Catalyst for production of propylene and ethylene with carbon alkatetraenes, regeneration and uses thereof

A technology for producing carbon tetraolefins and carbon tetraolefins, which is applied in the direction of catalyst regeneration/reactivation, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of poor selectivity and short service life, and achieve convenient operation and low reaction temperature , The effect of simple preparation method and regeneration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

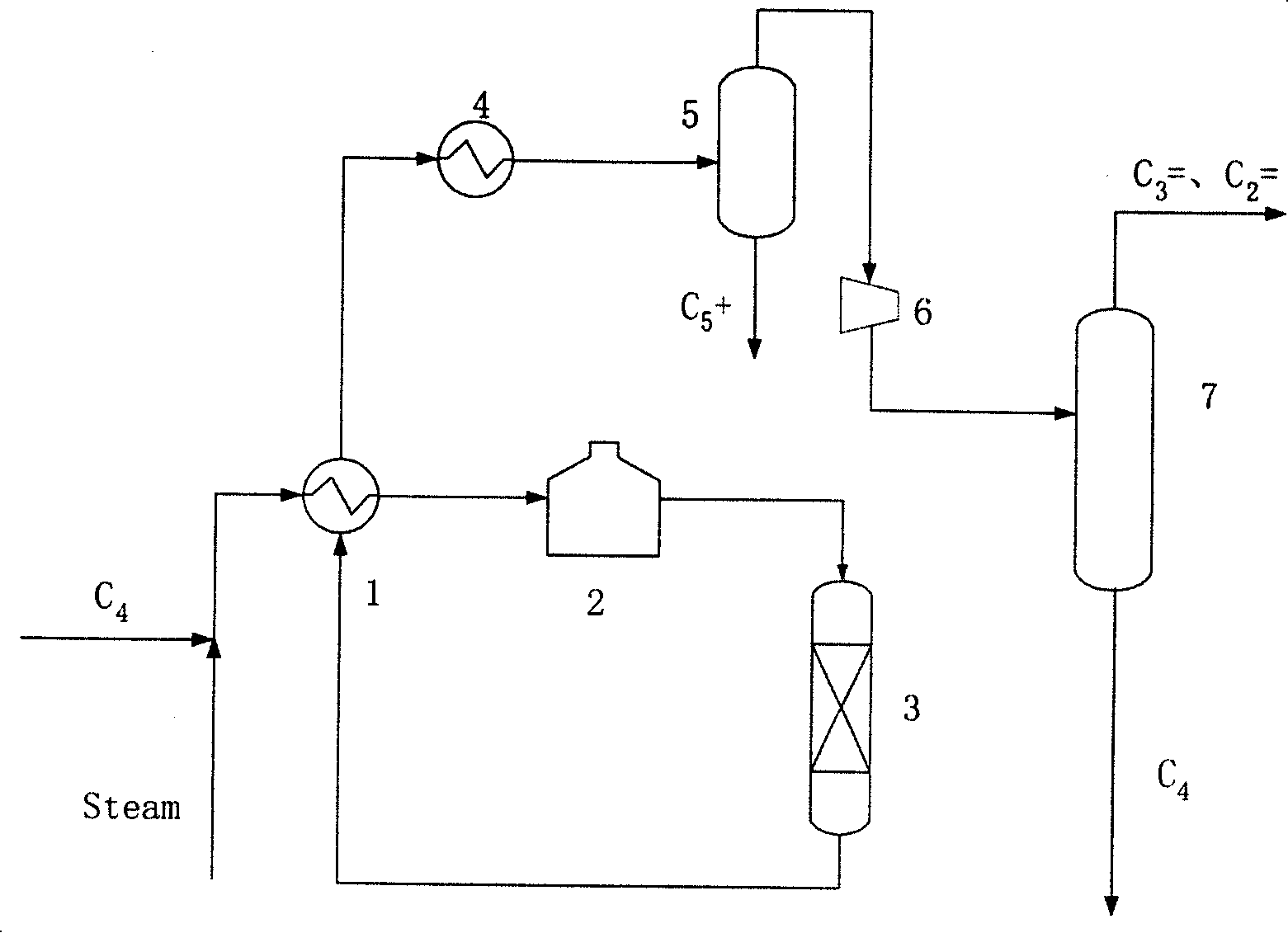

Method used

Image

Examples

Embodiment 1

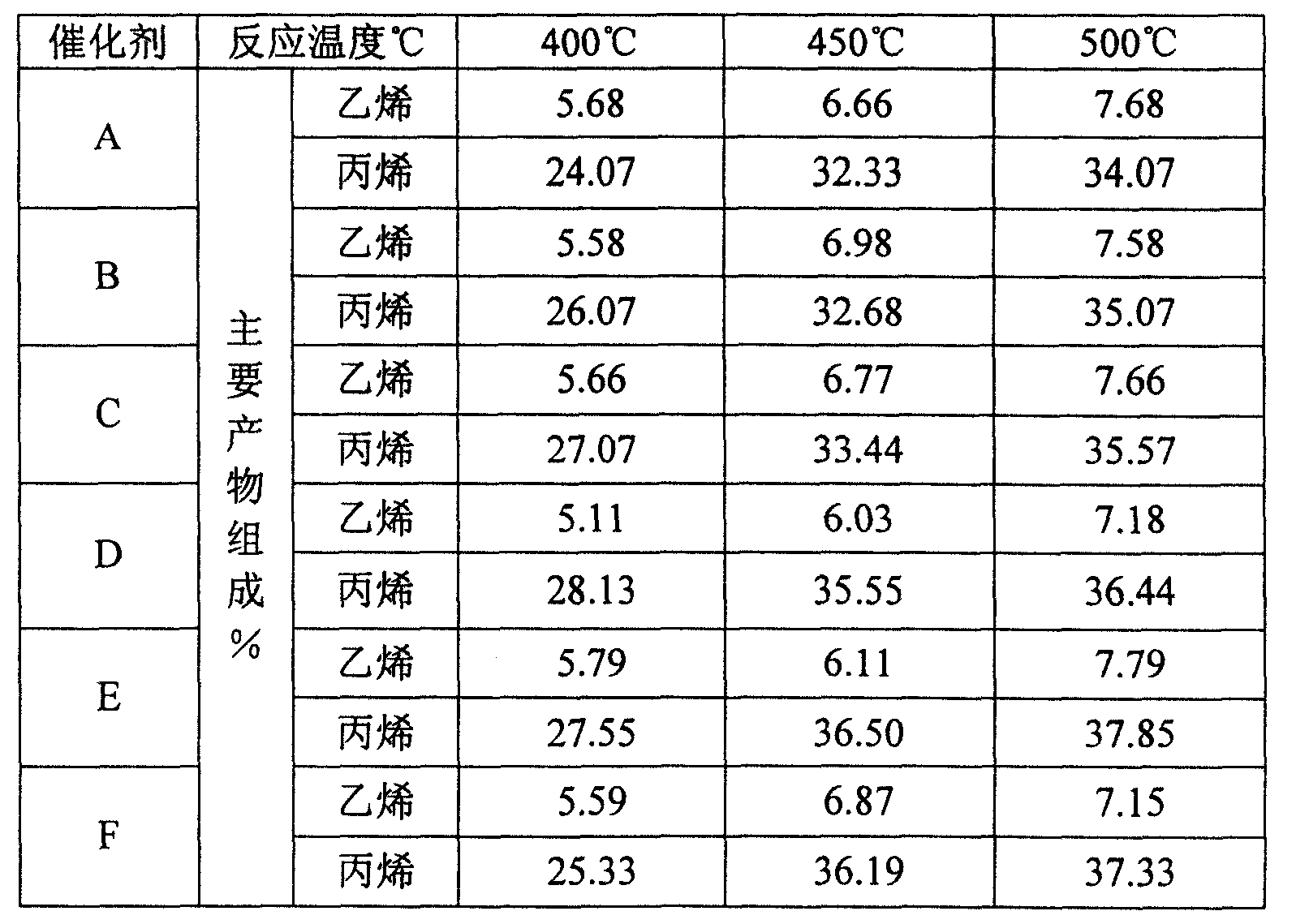

[0039] Embodiment 1 prepares catalyst A

[0040] 50g ZRP molecular sieve (SiO 2 / Al 2 o 3 >200), 50g of silicon oxide, 2g of scallop powder; mix well, add 80ml of 5% nitric acid, mix well, extrude into 2mm cylindrical shape, and cut into 2-3mm; dry at 80°C and 120°C respectively After 10 hours, it was calcined at 580° C. for 6 hours, taken out, and cooled to room temperature. The obtained catalyst was denoted as Catalyst A. Put in a desiccator for later use.

Embodiment 2

[0041] Embodiment 2 prepares catalyst B

[0042] 45g ZRP molecular sieve (SiO 2 / Al 2 o 3 >200), 45g of silicon oxide, 10g of magnesium oxide and 2g of turnip powder were mixed, and after mixing, 80ml of nitric acid was added. Other operating methods are the same as in Example 1. The resulting catalyst is denoted Catalyst B.

Embodiment 3

[0043] Embodiment 3 prepares catalyst C

[0044] 45g ZRP molecular sieve (SiO 2 / Al 2 o 3 >200), 45g of silicon oxide, 10g of zirconia and 2g of turnip powder were mixed, and after mixing, 80ml of nitric acid was added. Other operating methods are the same as in Example 1. The resulting catalyst is denoted Catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com