Waste landfill site preventing landfill gas escape by using waterproof mat

A landfill and waterproof pad technology, which is applied in the fields of landfill technology, solid waste removal, protection devices, etc., can solve problems such as cracks, and achieve the effects of preventing the greenhouse effect, improving air quality and structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

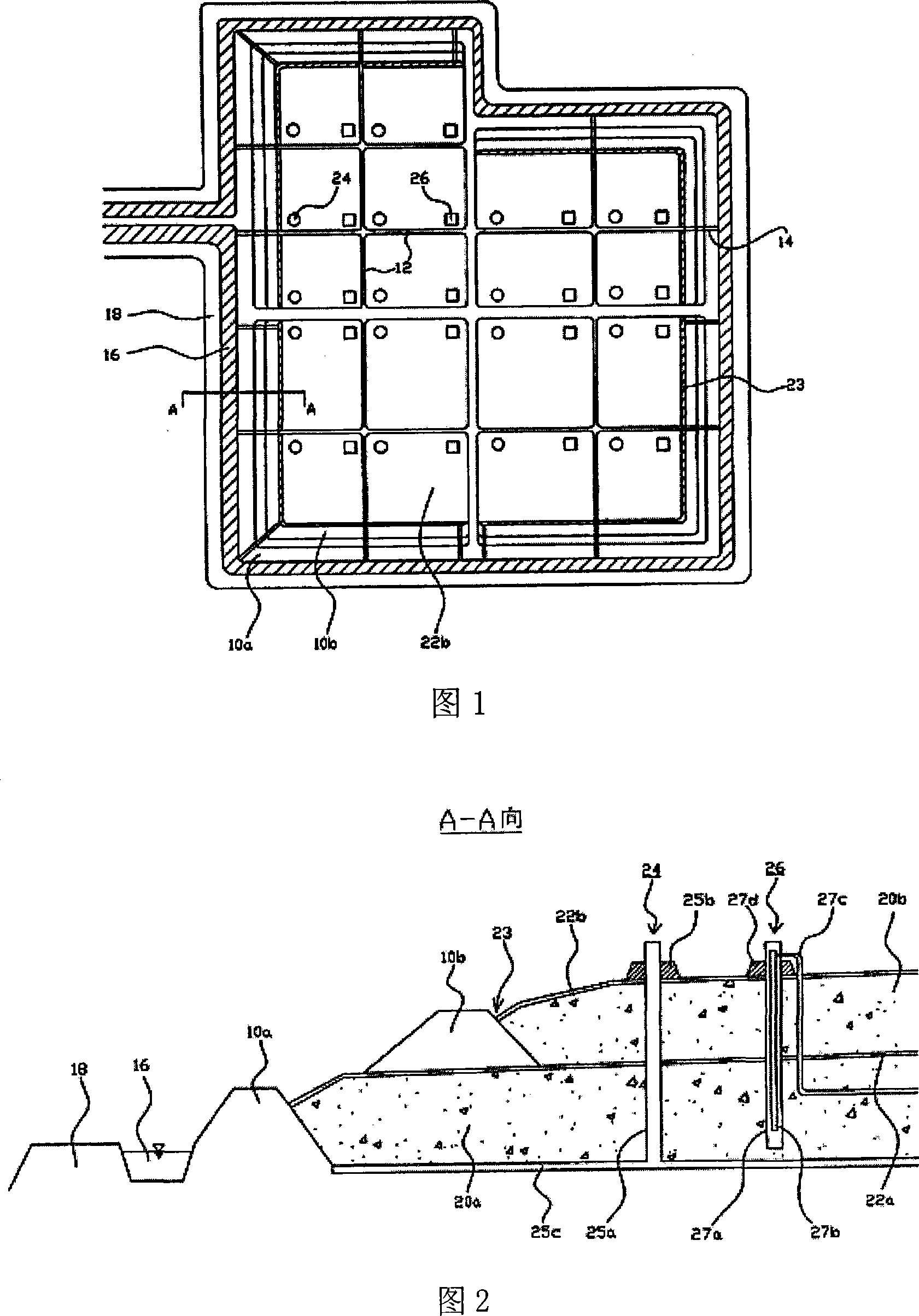

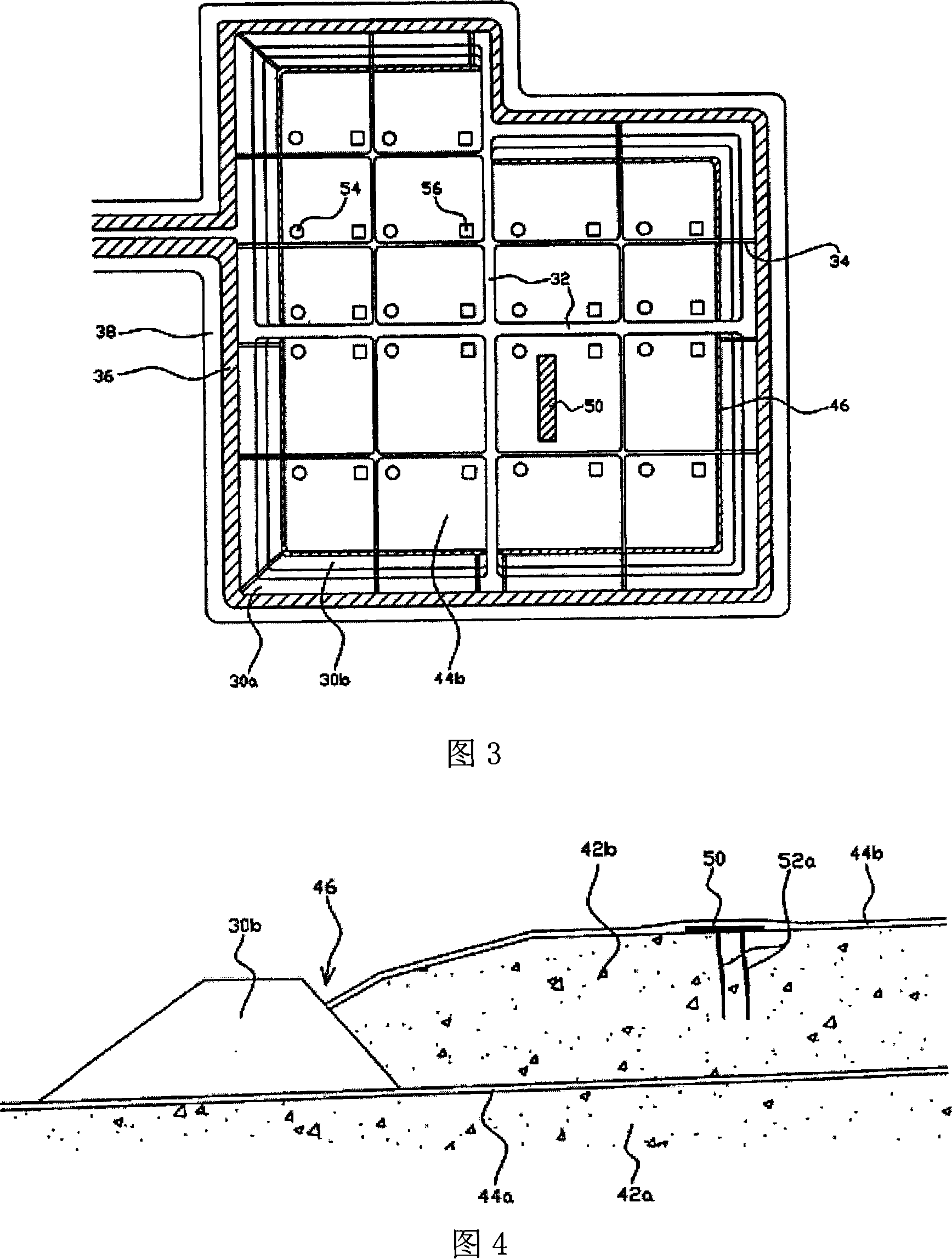

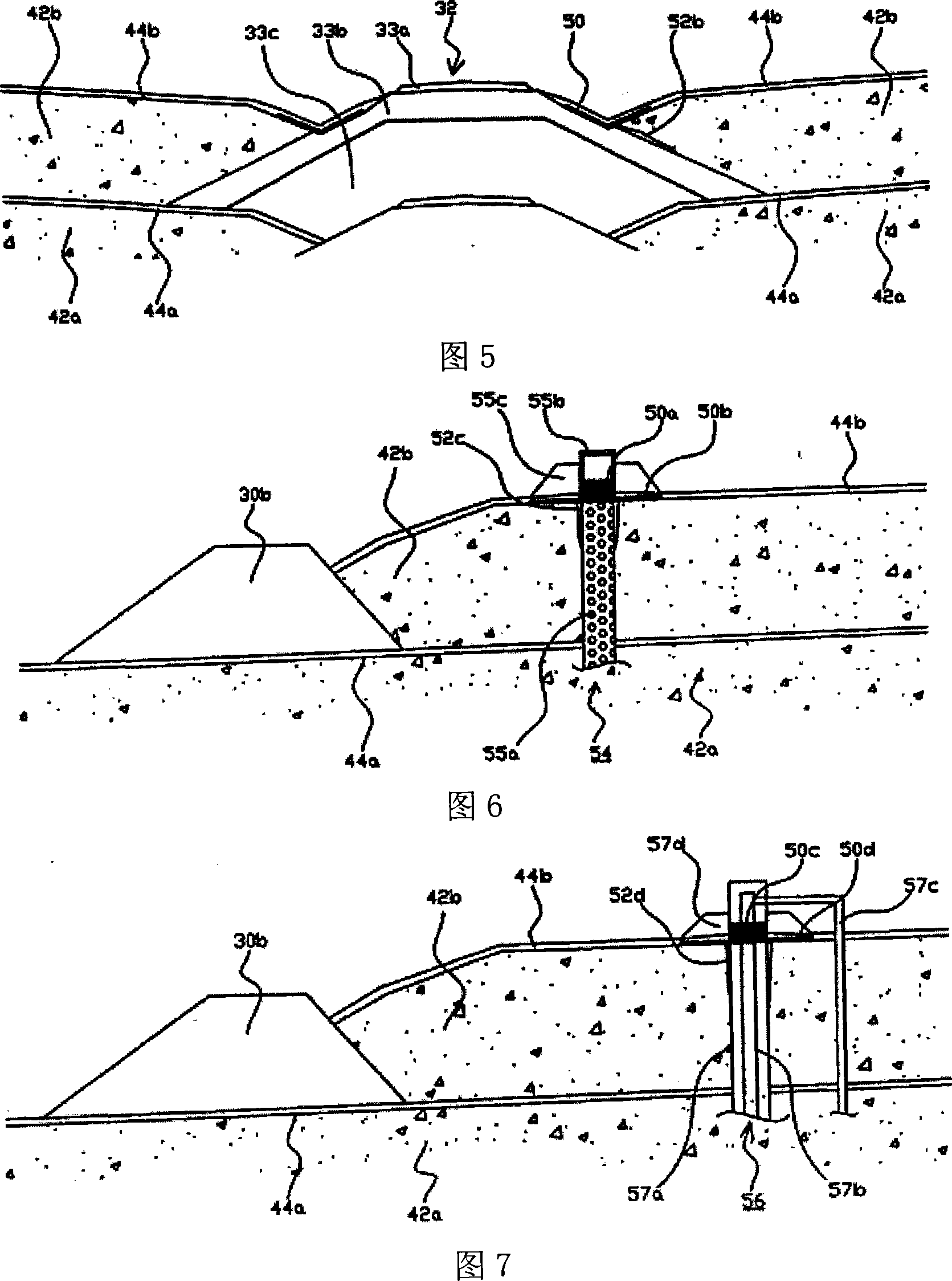

[0019] Hereinafter, a landfill site in which leakage of landfill gas can be prevented by using a waterproof pad according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0020] Fig. 3 is a top view of a landfill that can use a waterproof pad to prevent leakage of landfill gas according to an embodiment of the present invention. The schematic diagram of the waterproof pad 50 of the covering soil layer 44b, referring to FIG. 3 and FIG. 4, illustrates a landfill site according to an embodiment of the present invention.

[0021] The landfill site includes: more than one layer of landfill layers 42a, 42b, whose size gradually becomes smaller as they go up, and cover soil layers 44a, 44b are formed thereon; embankments 30a, 30b, which are formed on The edges of the landfill layers 42a, 42b are used to provide landfill space for garbage; the internal road 32, which is formed on the inner side of the embankments 30a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com