Antisludging agent of reverse osmosis water treatment system

A technology of scale inhibitor and weight percentage, applied in the field of water treatment chemicals, can solve the problems of low tolerance of iron ions, low scale inhibition performance, etc., and achieve the effects of reducing operating costs, prolonging service life, and improving dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

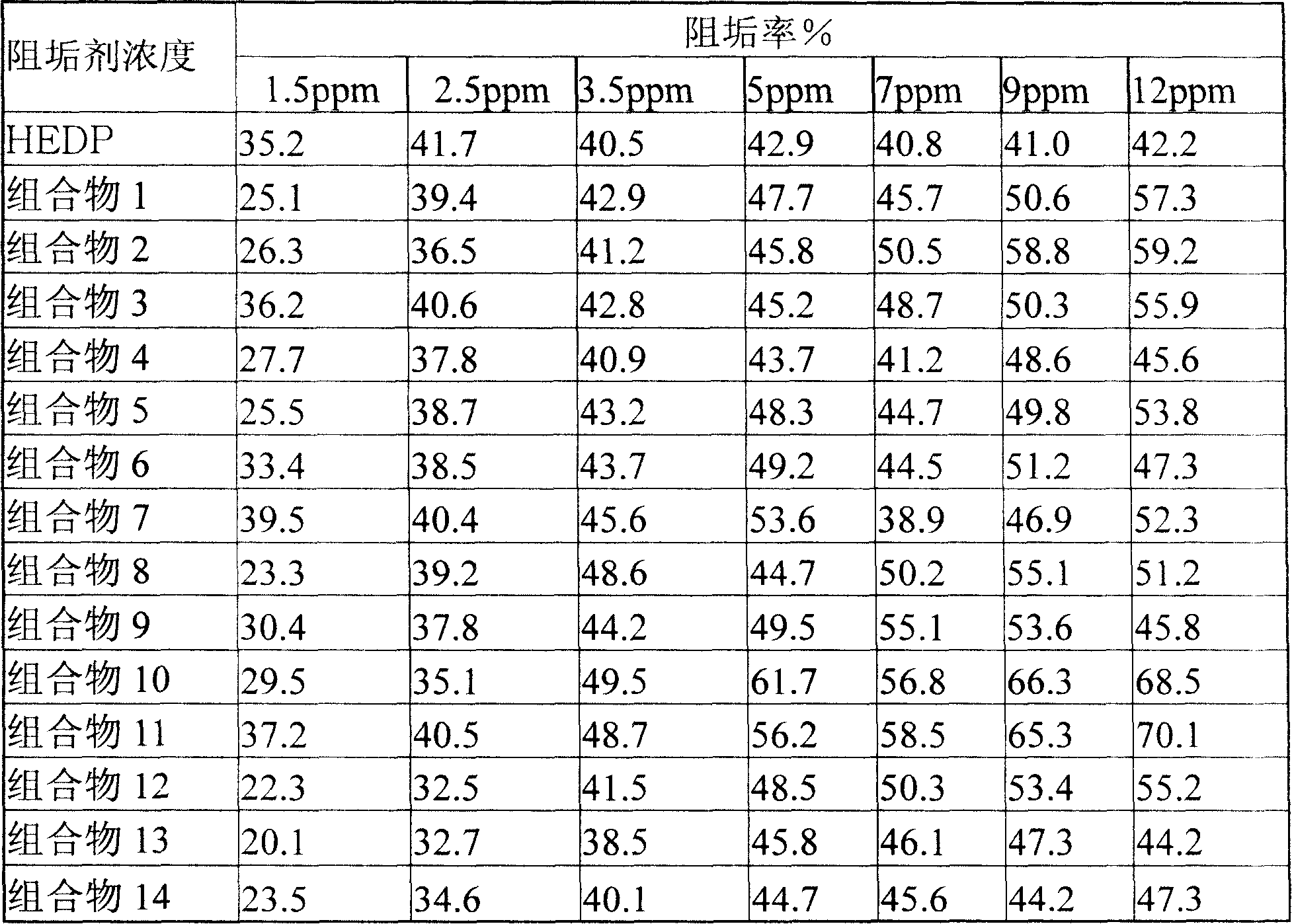

Examples

Embodiment 1

[0022] Example 1 Composition 1

[0023] 10% (weight percent: Wt) of hydroxyethylene diphosphonic acid; 25% (Wt) of diethylenetriamine pentamethylene phosphonic acid; 5% (Wt) of polyamino polyether group methylene phosphonic acid. Others are deionized water.

[0024] The preparation method is to mix the above raw materials with deionized water, stir evenly, let stand for 30 minutes, filter and fill.

Embodiment 2

[0025] Embodiment 2 Composition 2

[0026] Hydroxyethylene diphosphonic acid 15% (Wt); Diethylene triamine pentamethylene phosphonic acid 25% (Wt); Polyamino polyether group methylene phosphonic acid 5% (Wt); others are deionized water .

[0027] The preparation method is the same as in Example 1.

Embodiment 3

[0028] Embodiment three Composition 3

[0029] Hydroxyethylene diphosphonic acid 20% (Wt); Diethylene triamine pentamethylene phosphonic acid 25% (Wt); Polyaminopolyether group methylene phosphonic acid 15% (Wt); others are deionized water .

[0030] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com