Long-acting special controlled release fertilizer for corn and preparation method thereof

A corn-specific, controlled-release fertilizer technology, applied in the application, fertilization device, fertilizer mixture, etc., can solve the problem of inability to meet the needs of corn growth for nutrients, the complex preparation process of slow-release fertilizers, poor adhesion and closed continuity, etc. problems, to achieve the effects of low cost, prevention of leaching and fixation, and less process area

Inactive Publication Date: 2010-08-11

SHANDONG AGRICULTURAL UNIVERSITY

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a special controlled-release fertilizer for long-acting corn and its preparation method. The coating layer of the existing slow-release fertilizer is poor in toughness, brittle, easy to fall off, easy to break, poor in adhesion and sealing continuity technical problems; solve the complex problem of the existing slow-release fertilizer preparation process; and solve the problem that the existing fertilizer components cannot meet the nutritional requirements of corn growth

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

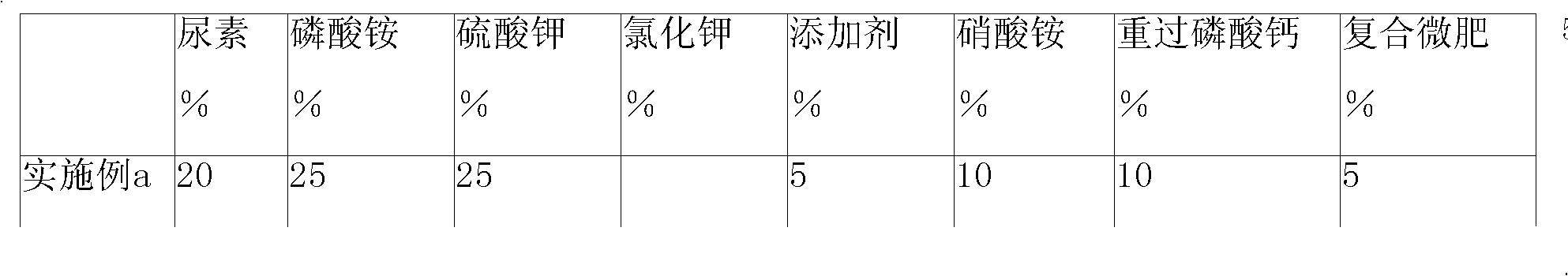

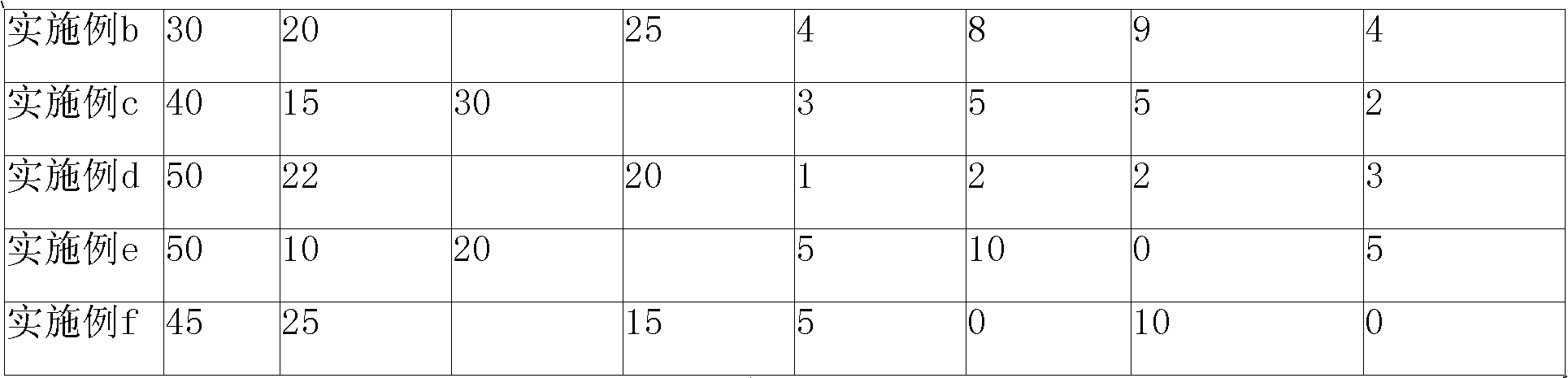

Embodiment 1

Embodiment 2

Embodiment h

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a special controlled release fertilizer for corn and a preparation method, which comprises a fertilizer core accounting for 80 to 92% of the total weight of the fertilizer, and a coating layer accounting for 8 to 20% of the total weight of the fertilizer; wherein, the weights of the nitrogenous fertilizer, phosphate fertilizer and potassium fertilizer are calculated respectively as pure nitrogen, phsophorus pentoxide and potassium chlorate, accounting for 25% to 50% of the total weight of the fertilizer with the weight ratio of 2 to 4:1 to 2:1 to 3; the coating layer comprises 69.5 to 93% sulfur, 530% polyethylene wax and 0.5 to 2% flow agent. The sulfur is melted, then is stirred uniformly after adding with montmorillonite, and, is stirred uniformly to form molten sulfur after adding with flow agent. The molten sulfur and polyethylene wax are synchronously sprayed on the surface of the fertilizer core, forming a slow released involucrum layer. The invention has the advantages of smaller area, less equipment investment and energy consumption, ability to meet the nutrient requirements in the whole corn growth period for one fertilization, long and safe fertilizer efficiency and simple fertilization.

Description

technical field The invention relates to a slow and controlled release fertilizer and a preparation method thereof, in particular to a special slow and controlled release fertilizer for corn and a preparation method thereof. Background technique In the prior art, the special fertilizer for corn is formed by mixing elemental chemical fertilizers containing nitrogen, phosphorus and potassium and micro-fertilizers according to a certain ratio. Nitrogen fertilizers used in fertilizer materials such as urea, ammonium chloride, ammonium sulfate, ammonium bicarbonate, etc., are prone to ammonia volatilization loss after application on calcareous soil. At the same time, after being converted into nitrate nitrogen by nitrifying bacteria in the soil , it is easier to leaching and loss; and the phosphorus in the fertilizer is also easier to combine with calcium, magnesium, iron and aluminum in the soil to grow insoluble precipitation; potassium is easy to be fixed by 2:1 clay minerals;...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C05G1/00C05G3/00

Inventor 史衍玺杨守祥董树亭王空军董元杰孔凡美

Owner SHANDONG AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com