Method for rapid purification of codonopsis pilosula lobetyolin monomer from codonopsis pilosula medicinal materials

A technology for the separation and purification of tangshenoside, applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve the problems of large solvent consumption, long time consumption, cumbersome solvent recovery, etc., and achieve low solvent consumption and short process cycle Short, solvent-intensive and labor-intensive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

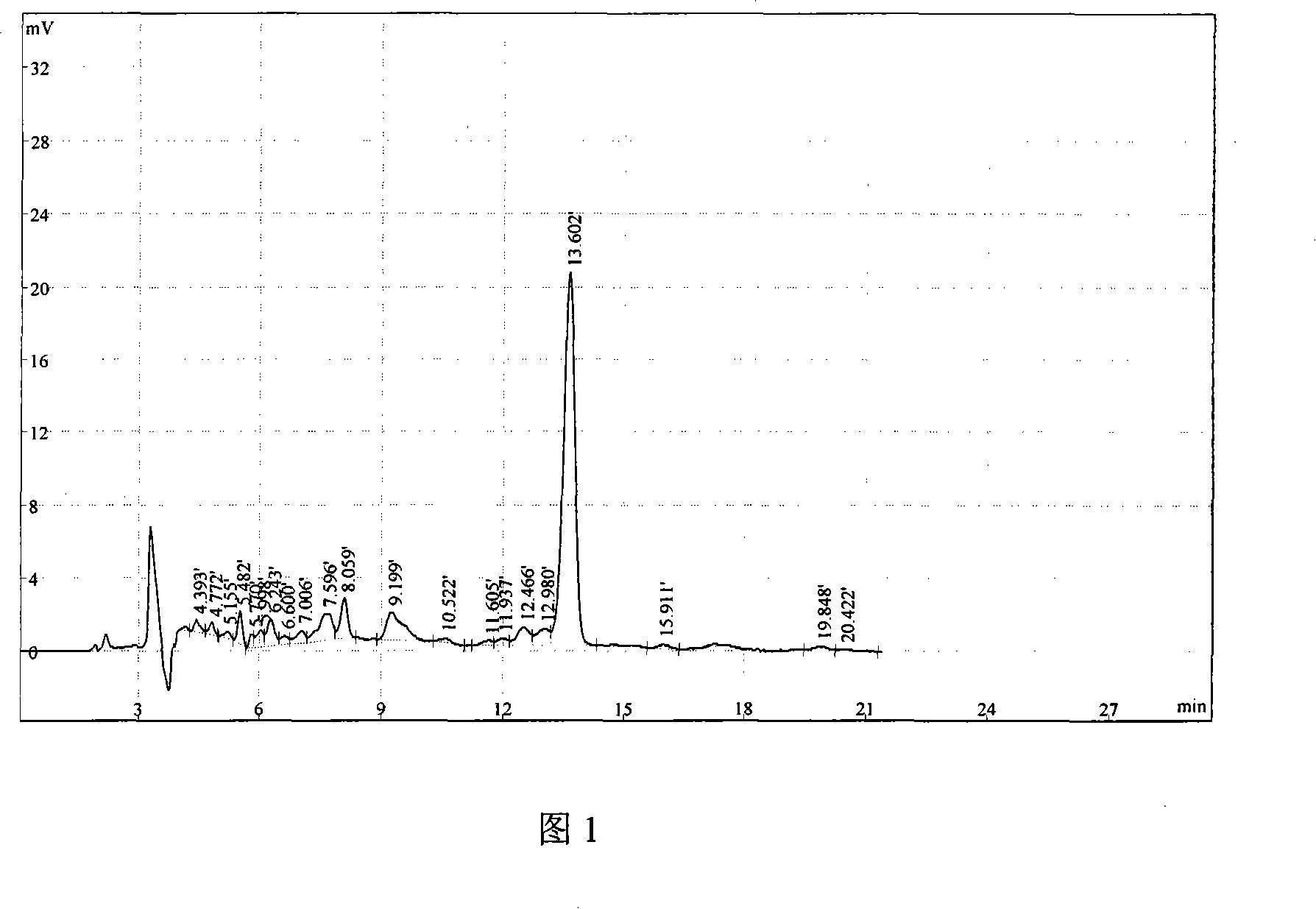

example 1

[0024] A method for rapidly separating and purifying tangshenoside monomers from Codonopsis pilosula medicinal materials produced in Shanxi, the following steps are carried out at 55°C:

[0025] A. Cold extraction: crush the dried roots of Codonopsis pilosula through a 60-mesh sieve, mix and soak them with ethanol for 24 hours, cold soak and filter to remove slag, and the obtained liquid is recovered under reduced pressure to remove ethanol to obtain a concentrated extract; the mixing ratio is the volume of Codonopsis pilosula powder and The volume ratio of ethanol or methanol is 1:3. The ethanol concentration was 95%.

[0026] B. Coarse separation of resin: After diluting the concentrated extract in the previous step with water, filter it with a fine gauze cloth of about 200 meshes to remove solid impurities such as sand and dust before applying the macroporous resin, and then pass it into the activated macroporous adsorption resin column, elute the macroporous adsorption re...

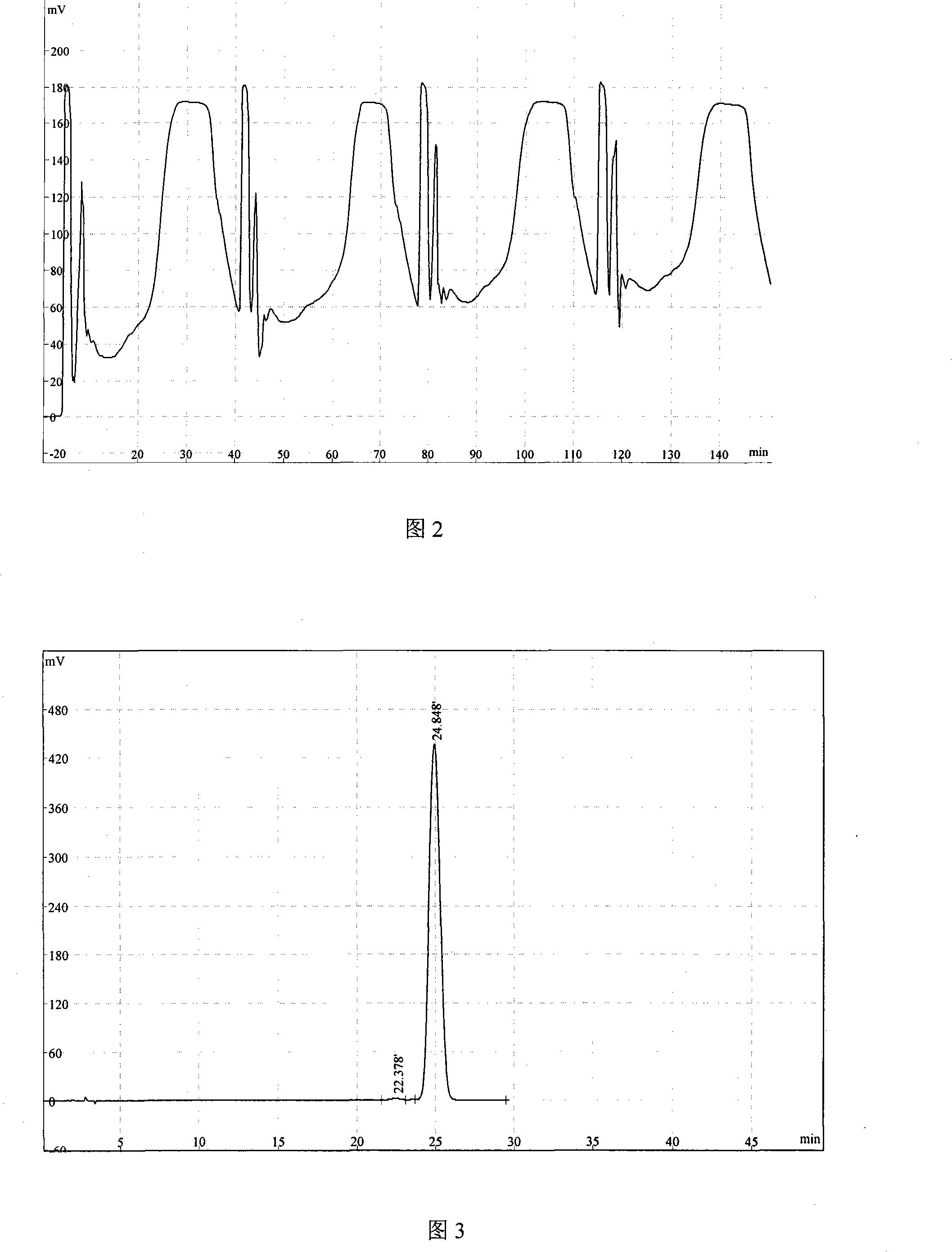

example 2

[0033] A method for rapidly separating and purifying tangshenoside monomers from Codonopsis pilosula medicinal materials produced in Shanxi, the following steps are carried out at 25°C:

[0034] A. Cold soaking extraction: mix and soak the dried tuber root powder of Codonopsis pilosula and ethanol for 36 hours, remove the slag by cold soaking and filtration, and recover the obtained liquid under reduced pressure to remove ethanol to obtain a concentrated extract; the mixing ratio is that the volume ratio of Codonopsis pilosula powder and ethanol is 1: 3; The concentration of ethanol is 100%, and the particle size of the dried tuber root powder of Codonopsis pilosula is 40 mesh.

[0035] B. Coarse separation of resin: After diluting the concentrated extract in the previous step with water, filter it with a fine gauze cloth of about 200 meshes to remove solid impurities such as sand and dust before applying the macroporous resin, and then pass it into the activated macroporous ad...

example 3

[0040] A method for rapidly separating and purifying tangshenoside monomers from Codonopsis pilosula medicinal materials produced in Shanxi, the following steps are carried out at 58°C:

[0041] A. Cold soaking extraction: Mix and soak the dried root tuber powder of Codonopsis pilosula and ethanol for 30 hours, then filter and remove the slag by cold soaking, and recover the obtained liquid under reduced pressure to remove ethanol to obtain a concentrated extract; the mixing ratio is that the volume ratio of Codonopsis pilosula powder and ethanol is 1: 3; The concentration of ethanol is 100%, and the particle size of the dried tuber root powder of Codonopsis pilosula is 100 mesh.

[0042] B. Coarse separation of resin: After diluting the concentrated extract in the previous step with water, filter it with a fine gauze cloth of about 200 meshes to remove solid impurities such as sand and dust before applying the macroporous resin, and then pass it into the activated macroporous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com