Full-automatic general analyzer control circuit

A conventional analysis and control circuit technology, applied in the direction of analyzing materials, material analysis by optical means, instruments, etc., can solve the problems of cross-infection, large error in results, difference in detection results, etc., and achieve the effect of improving repeatability and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

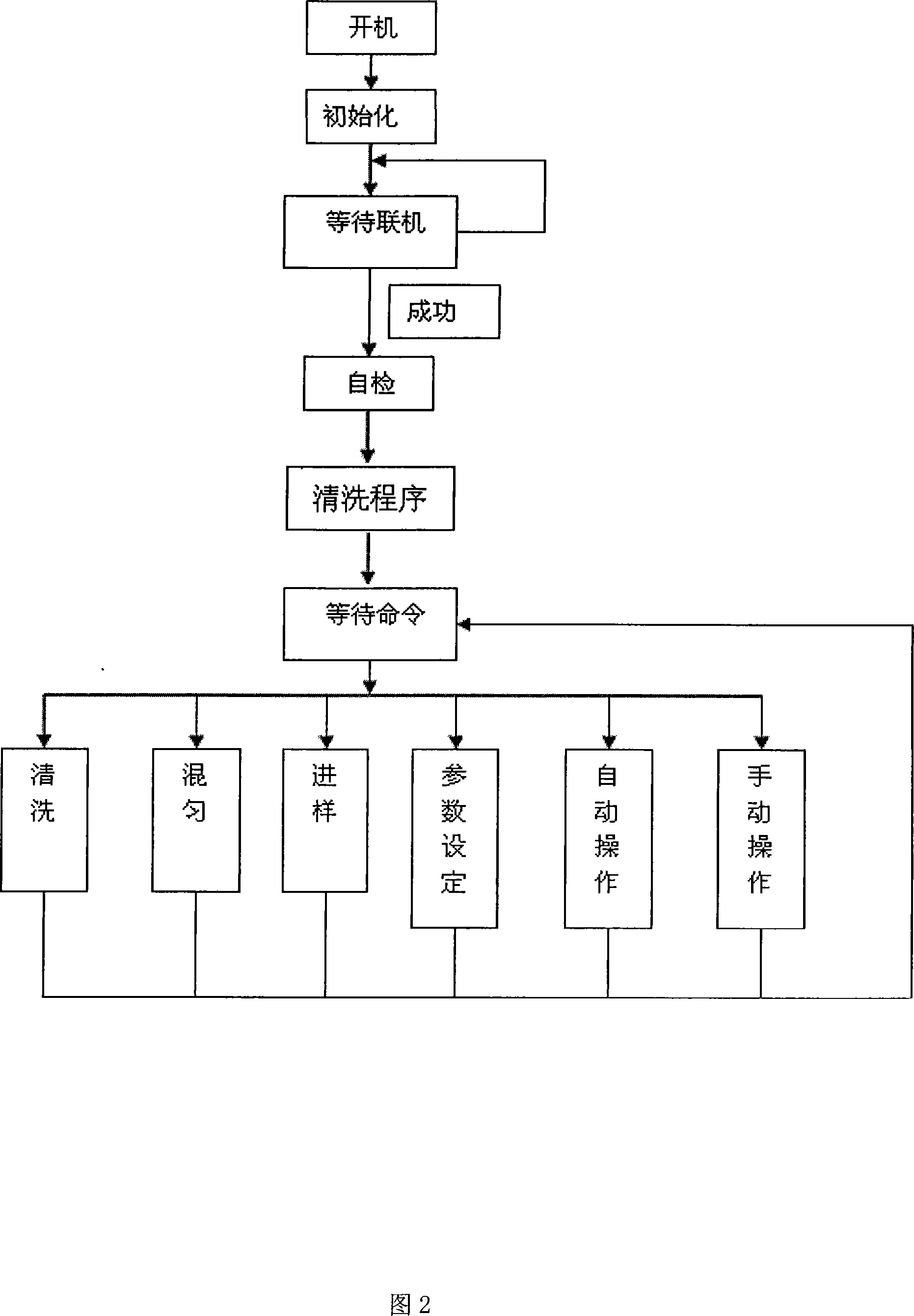

[0013] Figure 1 is the flow chart of the program design of the present invention. After starting up, the system initializes and waits for online connection. After the online connection is successful, the instrument performs self-inspection, and the solenoid valve self-inspects in turn. What you hear is the crisp sound of the solenoid valve opening. If there is any abnormality , you can turn off the power to check. After the self-test is completed, the instrument enters the cleaning program to clean the pipeline system. After cleaning, it is in standby mode, waiting for commands. Next, you can enter the cleaning, mixing, sample injection, parameter setting, automatic operation, and manual operation procedures in sequence.

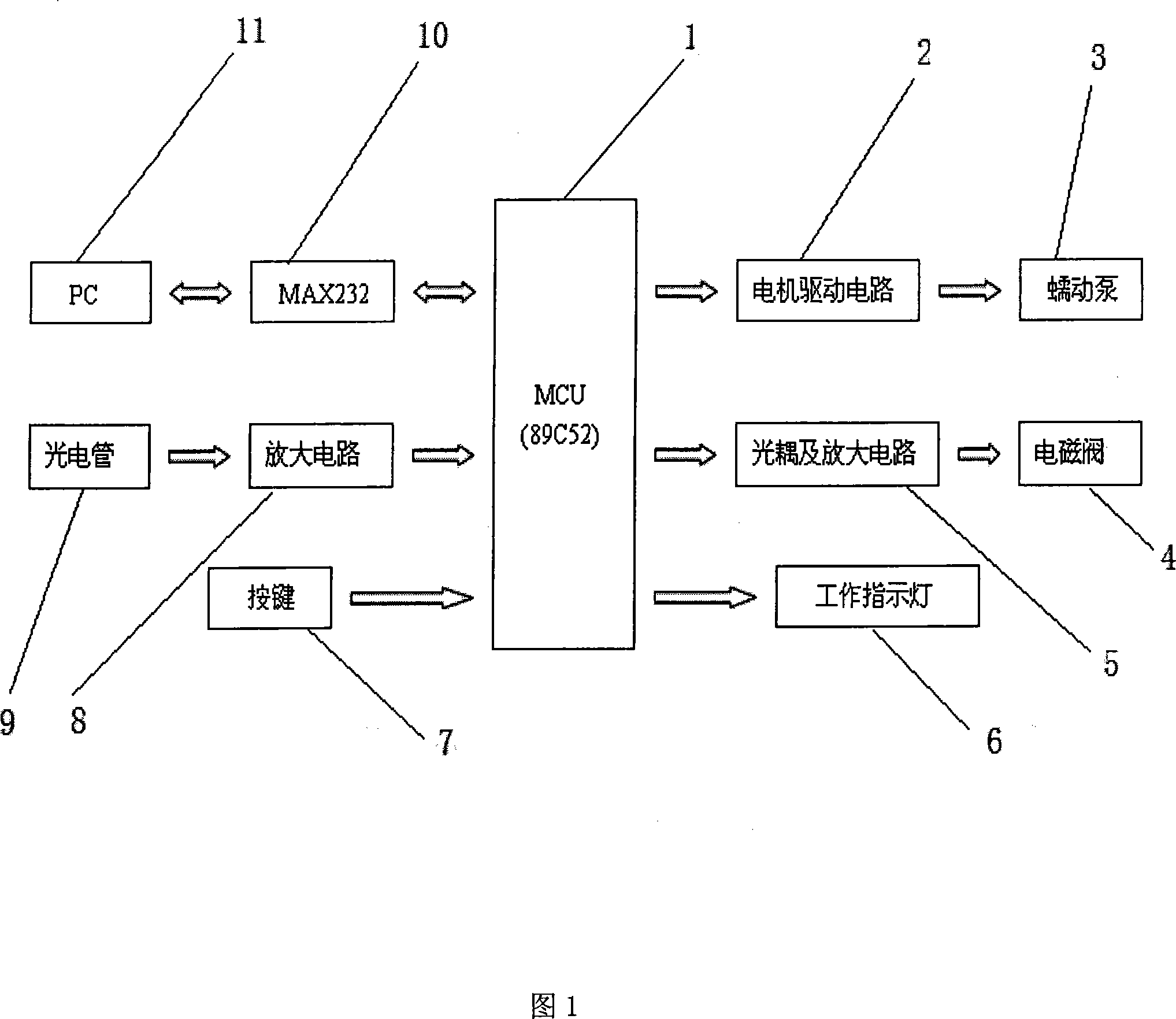

[0014] Fig. 2 is the circuit design block diagram of the present invention, and this invention circuit part is mainly by MCU1, motor drive circuit 2, peristaltic pump 3, optocoupler and amplifying circuit 4, electromagnetic valve 5, working indicator light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com