Method for preparing phytase taking glycerol as carbon source

A technology of phytase and glycerol, applied in the field of preparing phytase, can solve the problems of unfavorable yeast growth, increase production process and cost, etc., and achieve the effect of reducing processing cost, production cost and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

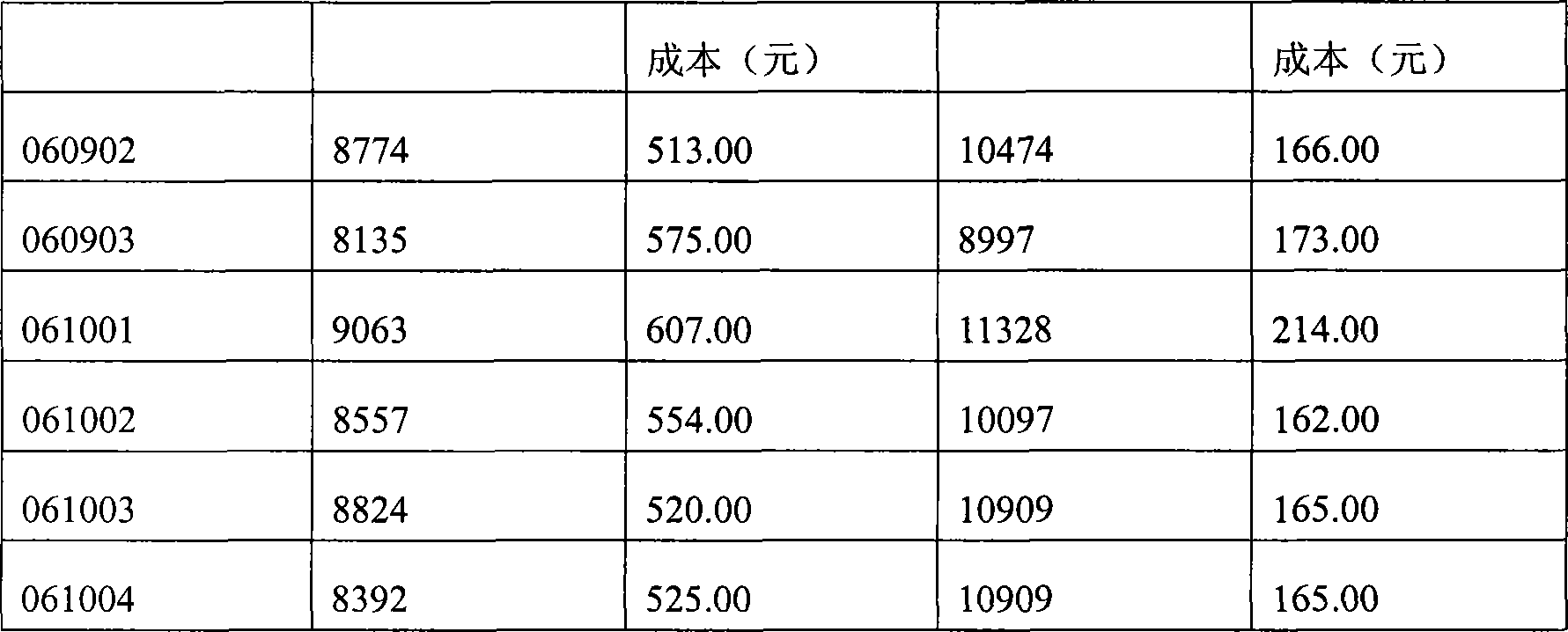

[0009] A method for preparing phytase using glycerol as a carbon source, adopting the fermentation production process of phytase-producing genetically engineered bacteria using Pichia pastoris as a carrier, is characterized in that glycerol is used as a carbon source, and glycerol as a carbon source is The fermentation stage is added in two steps: the first step is added with the basic fermentation medium, and the second step is added with 50% glycerin solution in the production fermentation.

[0010] The specific process is as follows:

[0011] 1. Culture medium

[0012] 1. Seed medium: 0.5-5% glycerin, 0.5-5% peptone, 0.1-2% yeast powder, according to the percentage of dissolution, and the rest is water;

[0013] 2. Fermentation medium: glycerol 1-10%, potassium dihydrogen phosphate 1-8%, potassium chloride 1-2%, ammonium sulfate 0.3-3%, potassium hydroxide 0.5-5%, biotin 0.02-0.2% , the rest is water;

[0014] 3. The trace element is PTM1 type, and the added amount is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com