Method of producing oxygen-containing soft magnetic ribbon for high frequency

A thin strip and soft magnetic technology, applied in the direction of magnetic properties of inorganic materials, can solve the problems of unfavorable large-scale production, difficult process control, complicated preparation process, etc., and achieve the effects of excellent high-frequency performance, large energy consumption, and simplified process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

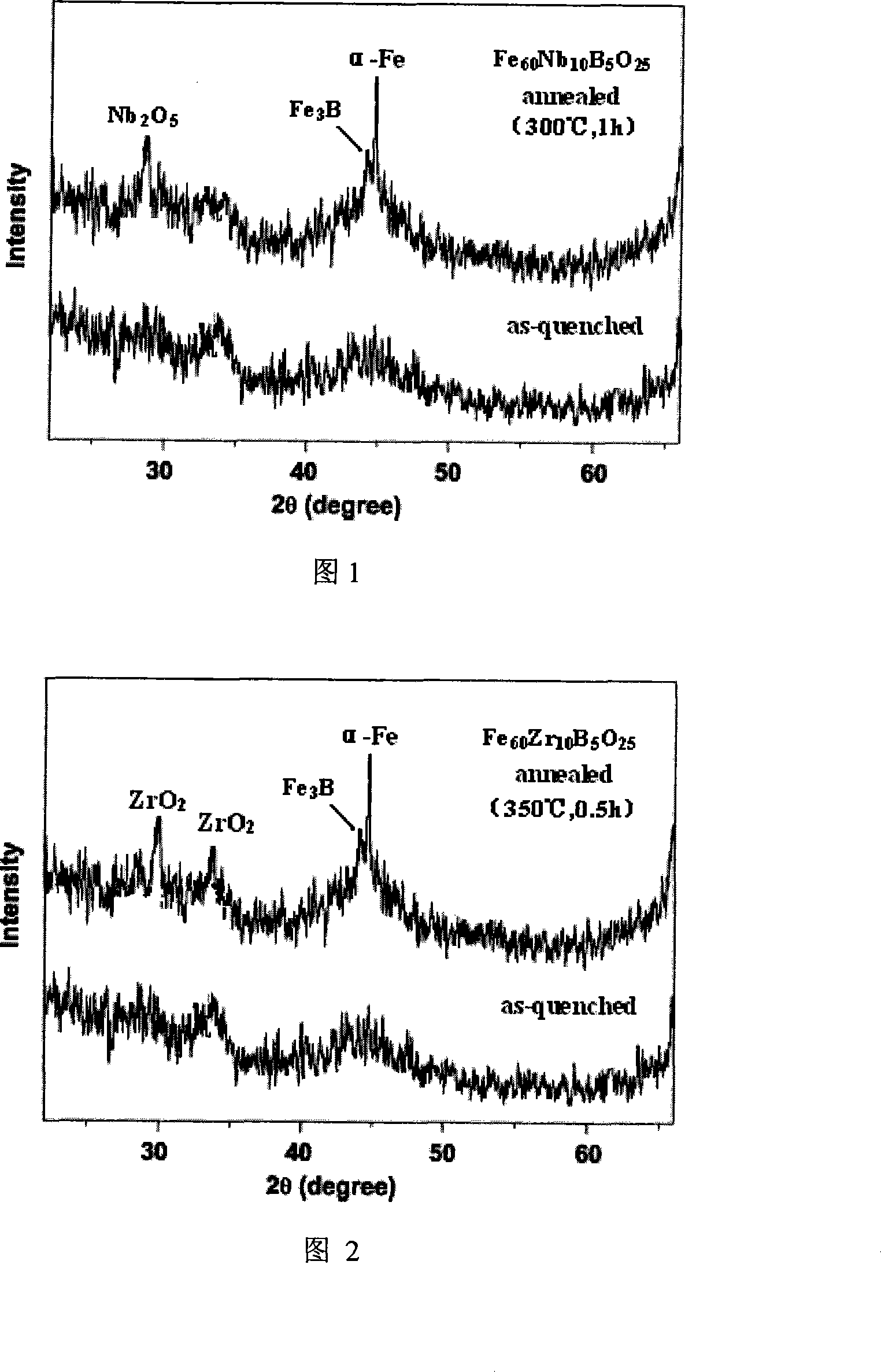

[0032] With pure iron, ferroferric oxide, pure niobium, ferroboron (Fe 82.73 B 17.67 ) as raw material, respectively 21.3%, 30.5%, 19.6%, and 28.6% by mass fraction to prepare ingredients for smelting Fe 60 Nb 10 B 5 o 25 Then cut the master alloy into small cubic pieces with a size of about 1cm×1cm×1cm, use a polishing machine for surface polishing treatment, and then clean the surface with acetone solution, and then package it in a quartz crystal with a zirconia crucible and a nozzle. In the glass tube, evacuate to 1×10 -4 Pa. Use intermediate frequency induction heating equipment to heat the quartz tube, the initial heating power is 5kW, and gradually increase to 15kW after the alloy turns red, and continue heating for 3 minutes after the alloy is completely melted, so that the alloy is fully stirred evenly, and then argon gas is introduced into the quartz tube , the argon pressure is 15kPa, and under the action of argon pressure, the melt is quickly sprayed from the ...

Embodiment 2

[0034] With pure iron, ferric oxide, pure zirconium, ferroboron (Fe 82.73 B 17.67 ) as raw material, respectively 21.4%, 30.6%, 19.3%, and 28.7% by mass fraction to prepare ingredients for smelting Fe 60 Zr 10 B 5 o 25 Then cut it into small cubic pieces with a size of about 1cm×1cm×1cm, use a polishing machine for surface polishing treatment, and then clean the surface with acetone solution, and then package it in a quartz glass with a zirconia crucible and a nozzle Inside the tube, evacuate to 5×10 -4 Pa. Use intermediate frequency induction heating equipment to heat the quartz tube, the initial heating power is 5kW, and gradually increase to 20kW after the alloy turns red, and continue heating for 5 minutes after the alloy is completely melted, so that the alloy is fully stirred evenly, and then argon gas is introduced into the quartz tube , the argon pressure is 15kPa, and under the action of argon pressure, the melt is quickly sprayed from the nozzle at the lower en...

Embodiment 3

[0036] With pure iron, ferroferric oxide, pure titanium, ferroboron (Fe 82.73 B 17.67 ) as raw material, respectively 9.34%, 26.74%, 19.9%, and 44.02% by mass fraction to prepare ingredients for smelting Fe 55 Ti 18 B 7 o 20 Then cut it into small cubic pieces with a size of about 1cm×1cm×1cm, use a polishing machine for surface polishing treatment, and then clean the surface with acetone solution, and then package it in a quartz glass with a zirconia crucible and a nozzle Inside the tube, evacuate to 1×10 -4 Pa. Use intermediate frequency induction heating equipment to heat the quartz tube, the initial heating power is 5kW, and gradually increase to 20kW after the alloy turns red, and continue heating for 4 minutes after the alloy is completely melted, so that the alloy is fully stirred evenly, and then argon gas is introduced into the quartz tube , the argon pressure is 10kPa, and under the action of argon pressure, the melt is quickly sprayed from the nozzle at the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com