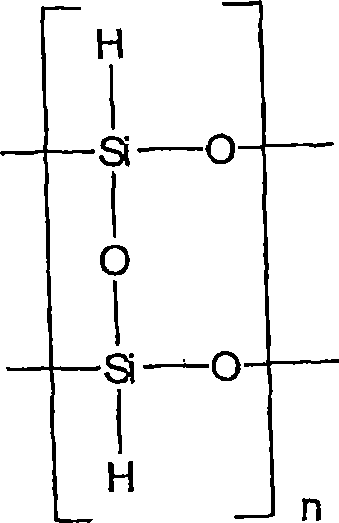

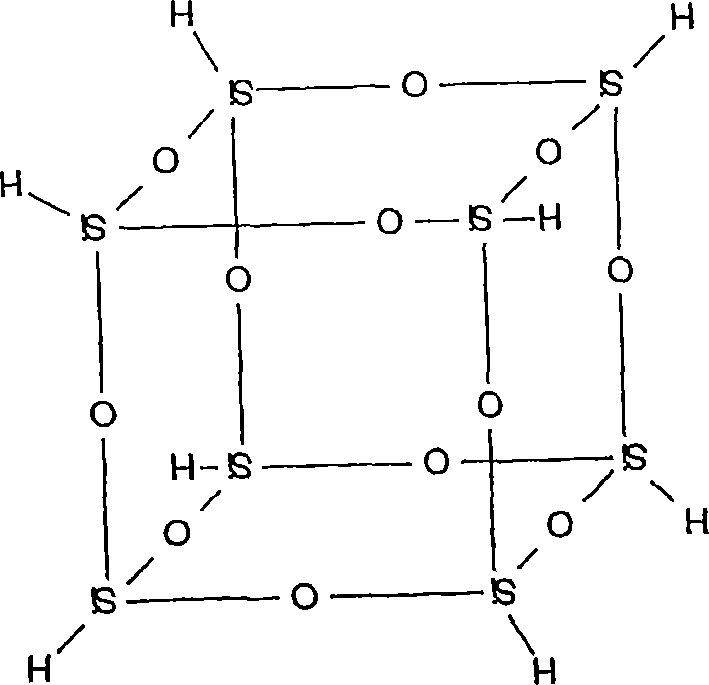

Method of curing hydrogen silses quioxane and densification in nano-scale trenches

A hydrogen silsesquioxane, densification technology, applied in nanotechnology, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as difficult to fill trenches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

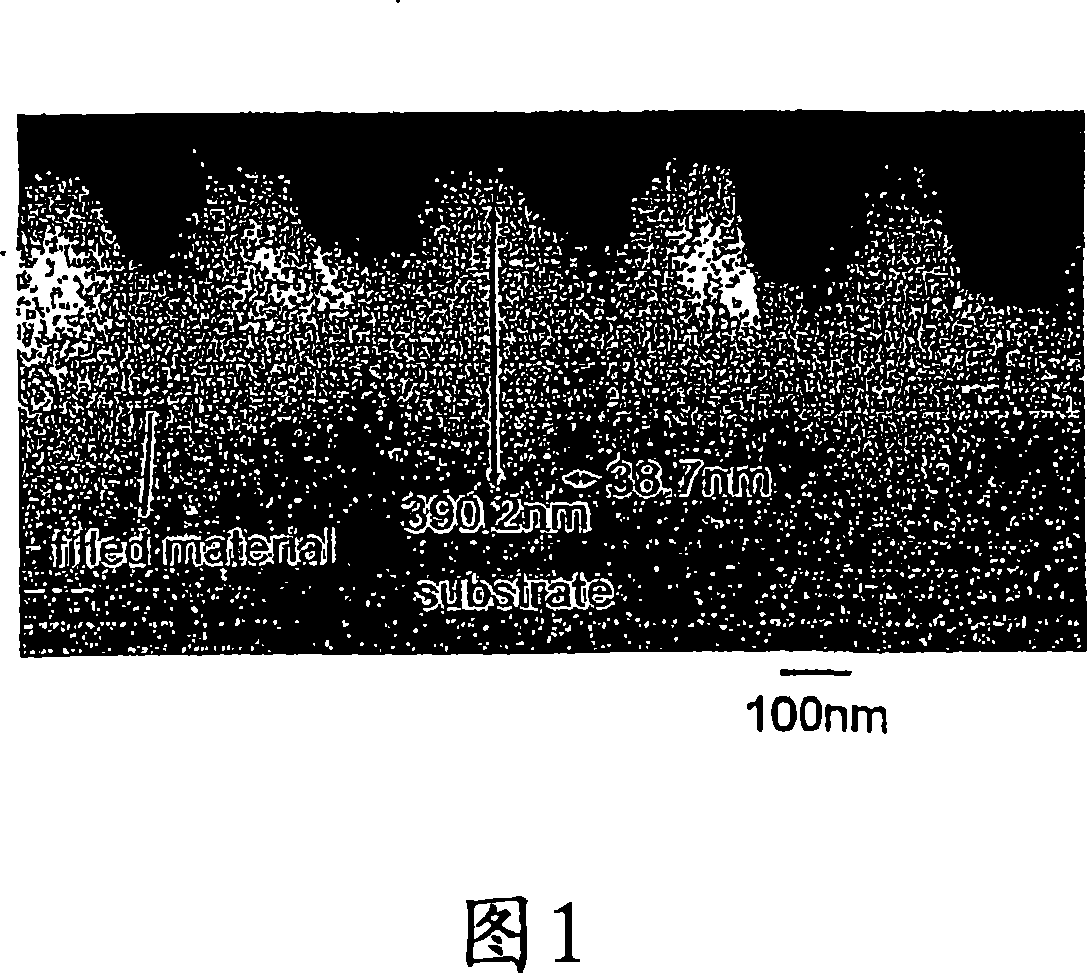

[0029] Two finely filtered HSQ solutions containing 4wt% and 8wt% HSQ in octamethyltrisiloxane were used. The film is spin-coated on the surface of the silicon wafer. In the first low temperature curing step, the film was initially kept at 100°C for 30 minutes in a water vapor environment. In the second low-temperature curing step, the temperature was increased to 250°C over 1 hour in a water vapor environment. During these two low temperature curing steps, water vapor remains in the grooves and reacts with HSQ. Then, in the third high temperature curing step, the film is further cured at 800° C. for 1 hour in a water vapor or nitrous oxide environment. The film was etched by exposing the film to a 200:1 hydrofluoric acid aqueous solution for 60 seconds, and the film loss was measured. The resulting film is shown in FIG. 1.

Embodiment 2

Example 2-Comparison

[0030] Example 1 was repeated at 800°C using normal oxidative curing but without water vapor. The etching resistance of the film was not observed. The filling material in the trench is completely removed.

Embodiment 3

[0031] Repeat Example 1, and nitrous oxide (N 2 O) Under the environment, further densify the cured HSQ film in the nano-scale trench of the silicon wafer. In particular, different temperatures were used to measure the curing of the HSQ resin film coated on the silicon wafer in a nitrous oxide environment. Using the same HF etching process as described in Example 1, the wet etching resistance in the nano-scale trench was measured. The process time for each measurement is 1 hour. As shown in Table 1, compared with the HSQ film cured in an oxygen or nitrogen environment, the film loss of the HSQ film cured in nitrous oxide is reduced in the dilute HF solution. In particular, at 800°C, the HSQ film cured under nitrous oxide has a film loss equivalent to that of a thermal oxide film. The values of the thermal oxide film in Table 1 are published data in the literature. Table 1 also shows the increase in mechanical properties (ie, hardness and modulus) of the HSQ film cured under nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com