Method for producing ethanol from crop straw

A crop straw and ethanol technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of increased production costs, large heat energy, increased costs, etc., and achieve the effect of reducing production and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

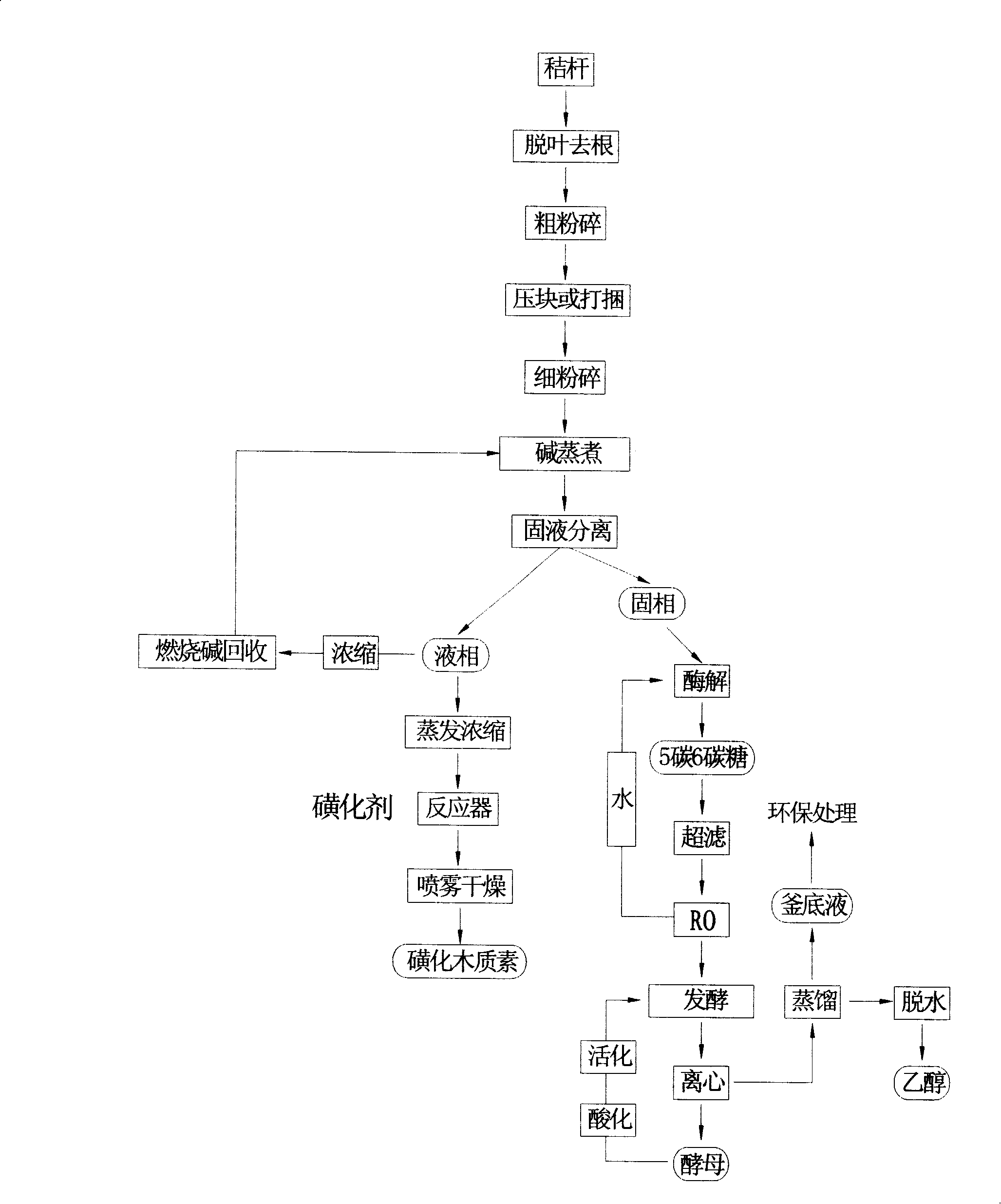

Method used

Image

Examples

Embodiment 1

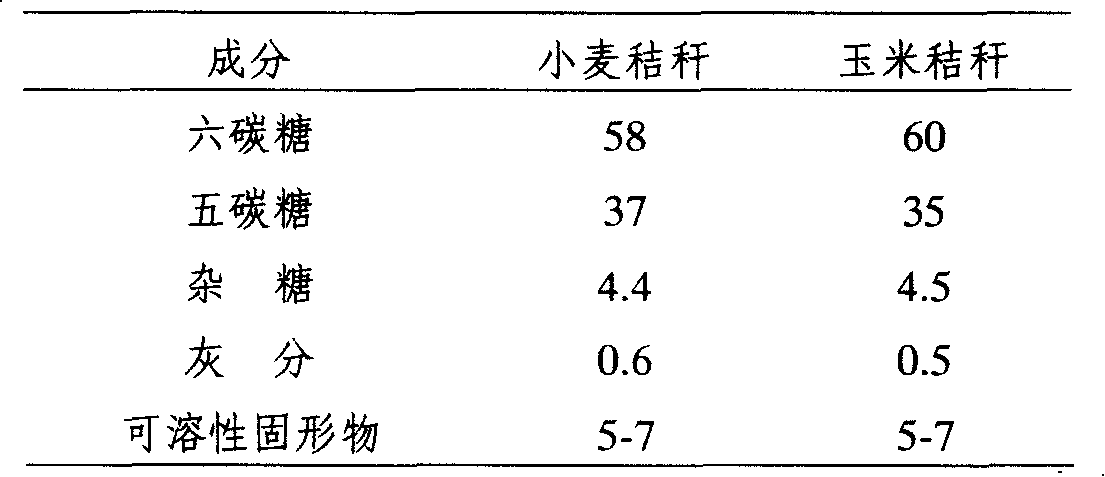

[0043] Embodiment 1. The processing of corn stalk

[0044] Take 100 kg of corn stalks, remove the leaves and roots by hand, and use the straw feed kneading machine (Wanqing 9STC-400 machine) and SFSP56×36 chip grinder (Jiangsu Muyang Group) for processing, and the hole diameter of the bottom discharge screen is Ф5' The straw powdery material is obtained.

Embodiment 2

[0045] Embodiment 2. dilute lye cooking pretreatment

[0046] Take the reactor as 0.8m 3 , Cylindrical reactor with a rotation speed of 1r / min, electric heating. Open the flange cover at one end of the cylindrical reactor, add 100kg of pulverized straw lumps, then add 600kg, 1.8% NaOH aqueous solution, cover the flange cover, and tighten it. Heat to 120°C under rotation, hold for 1 hour, then cool, open the flange and pour out the entire contents.

Embodiment 3

[0047] Embodiment 3. solid-liquid separation

[0048] The above-mentioned alkali-cooked materials are transferred to the DJG350 screw squeezer. Start the machine to collect liquid from the bottom and solids from the discharge end. After all the materials enter the squeeze dryer for the first time, add the collected solids, and add hot water at a ratio of 1:1 until all the materials enter the squeeze dryer.

[0049] Or use a separator (SS450 type three-legged upper discharge centrifuge, rotating speed 3000r / min, maximum loading capacity 30kg), separate 30kg of material each time, and centrifuge for 10min under the condition of 3000r / min to discharge the liquid. A solid with a water content of 65% to 75% is obtained. Take out the solids, put in water 5-6 times the weight of the solids, adjust the slurry, and then add it to a centrifuge for separation. Repeat twice continuously to reduce the alkali content in the stalks, and the pH of the water for the second washing is 9.0. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com