Process for the selective oxidation of ethane to ethylene

A technology of ethane and ethylene, which is applied in the field of ethylene preparation, and can solve the problems that a single catalyst cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

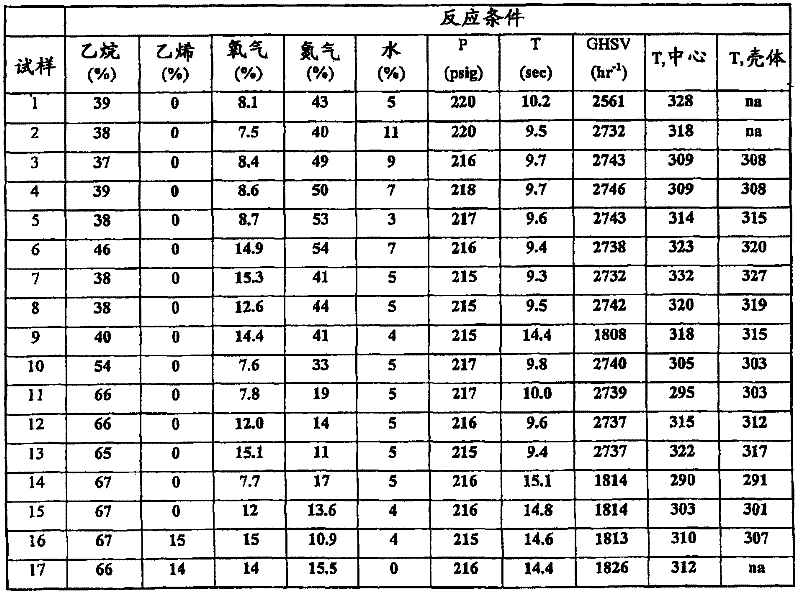

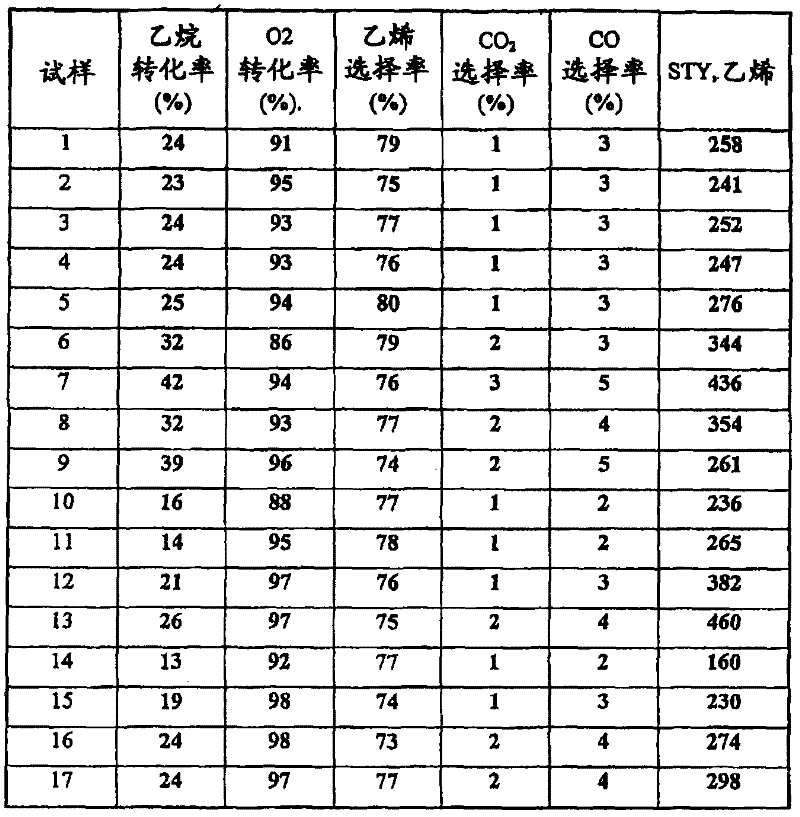

Image

Examples

Embodiment 1

[0032] Formula Mo is prepared as follows 1 V 0.33 Ta 0.12 Te 0.28 o z Catalyst: 25.0 g of ammonium heptamolybdate tetrahydrate (Aldrich Chemical Company), 5.47 g of ammonium metavanadate (Aldrich Chemical Company) and 9.10 g of telluric acid (Aldrich Chemical Company) were dissolved in 400 mL of water by heating to 80°C. After cooling to room temperature, 28.0 mL of an aqueous solution of tantalum oxalate (0.5M Ta, 1.5M oxalate) was added. Water was removed by a rotary evaporator in a warm water bath at 50°C to obtain a solid catalyst precursor. The solid was dried at 120°C before calcination.

[0033] The catalyst precursor solid was calcined at 600° C. for 2 hours in a nitrogen pre-purged lidded crucible. The oven was rapidly heated at 10°C / min to °C and held for 2 hours, followed by rapid heating at 10°C / min to 600°C and held at 600°C for 2 hours. The catalyst thus obtained was ground into a fine powder, pressed in a mould, followed by crushing and sieving to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com