Method for sorting color cotton imitation colored woven blank textile

A technology for weaving raw blanks and colored cotton, applied in biochemical equipment and methods, fiber treatment, textiles and papermaking, etc., can solve the problems of poor color fastness, environmental pollution, and easy fading of colored cotton, and achieve good control and softness The effect of improving sex and color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

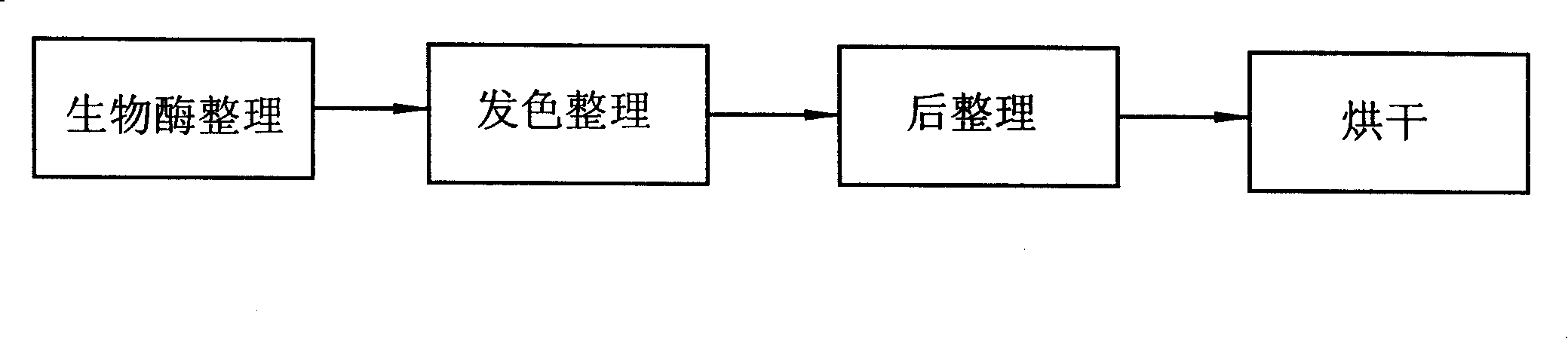

[0019] A kind of finishing method of colored cotton imitation yarn-dyed raw fabric of the present invention, it comprises such as figure 1 As shown, the colored cotton imitation yarn-dyed original fabric is subjected to biological enzyme finishing, color hair finishing, post-finishing and drying in sequence. In the biological enzyme finishing aqueous solution of the nonionic surfactant, wherein the compound scouring enzyme is composed of pectinase, amylase and cellulase, wherein pectinase accounts for 1% by weight of the biological enzyme finishing aqueous solution, amylase accounts for 3%, fiber The enzyme accounts for 2%, and the colored cotton imitation yarn-dyed original fabric is treated in an industrial washing machine at a temperature of 55° C. for 60 minutes in the biological enzyme finishing aqueous solution; then the colored cotton imitation yarn-dyed original fabric is dried; Cotton imitation yarn-dyed raw fabric is put into containing 0.3% fatty alcohol polyoxyethy...

Embodiment 2

[0022] A kind of finishing method of colored cotton imitation yarn-dyed raw fabric of the present invention, it comprises such as figure 1 As shown, the colored cotton imitation yarn-dyed original fabric is subjected to biological enzyme finishing, color hair finishing, post-finishing and drying in sequence. In the biological enzyme finishing aqueous solution of sodium carbonate and 0.08% industrial nonionic surfactant, the compound scouring enzyme is made up of pectinase and amylase, wherein pectinase accounts for 1.5% of biological enzyme finishing aqueous solution weight, and amylase accounts for 4%, the colored cotton imitation yarn-dyed original fabric is treated in an industrial washing machine with a temperature of 57 ° C for 80 minutes in the biological enzyme finishing aqueous solution; then the colored cotton imitation yarn-dyed original fabric is dried; and the colored cotton imitation color The woven raw fabric is put into the coloring and finishing aqueous solutio...

Embodiment 3

[0024] A kind of finishing method of colored cotton imitation yarn-dyed raw fabric of the present invention, it comprises such as figure 1 As shown, the colored cotton imitation yarn-dyed original fabric is subjected to biological enzyme finishing, color hair finishing, post-finishing and drying in sequence. In the bio-enzyme finishing aqueous solution of sodium carbonate used and 0.2% industrial nonionic surfactant, compound scouring enzyme is made up of pectinase and cellulase, and pectinase accounts for 1.5% of biological enzyme finishing aqueous solution weight, and cellulose Enzymes account for 2.5%, and the colored cotton imitation yarn-dyed original fabric is treated in an industrial washing machine with a temperature of 58 ° C for 80 minutes in the biological enzyme finishing aqueous solution; then the colored cotton imitation yarn-dyed original fabric is dried; The imitation yarn-dyed raw fabric is put into containing 0.4% fatty alcohol polyoxyethylene ether surfactan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com