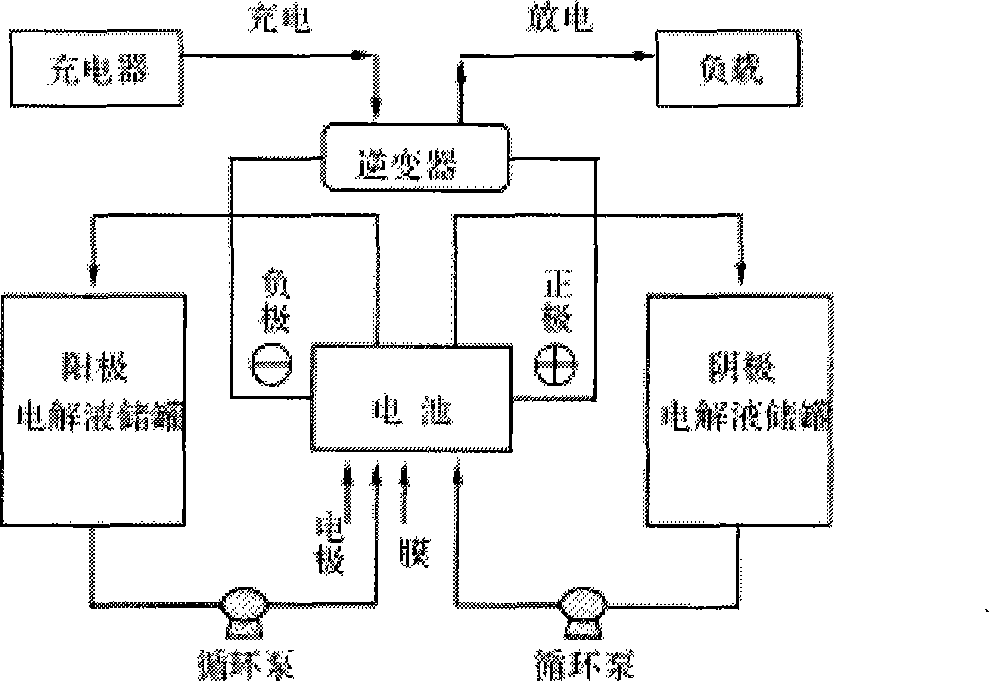

Large power redox flow cell device electric pile structure

A technology for flow batteries and stacks, which is applied in fuel cell components, fuel cells, and regenerative fuel cells, etc., can solve the problems of large-scale application of stacks, difficult processing and assembly, poor flow performance, etc. Discharge loss, improving assembly efficiency and effectiveness, improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] According to the structure design of this patent, an all-vanadium redox flow battery stack was built, and the charging and discharging experiments were carried out. Using V4+ / V5+ and V3+ / V2+ vanadium ions as the anode and cathode active materials of the redox flow battery respectively, the half-cell electrochemical reaction in the stack is as follows.

[0017] Positive reaction

[0018]

[0019] Negative reaction

[0020] E. 0 =-0.26V

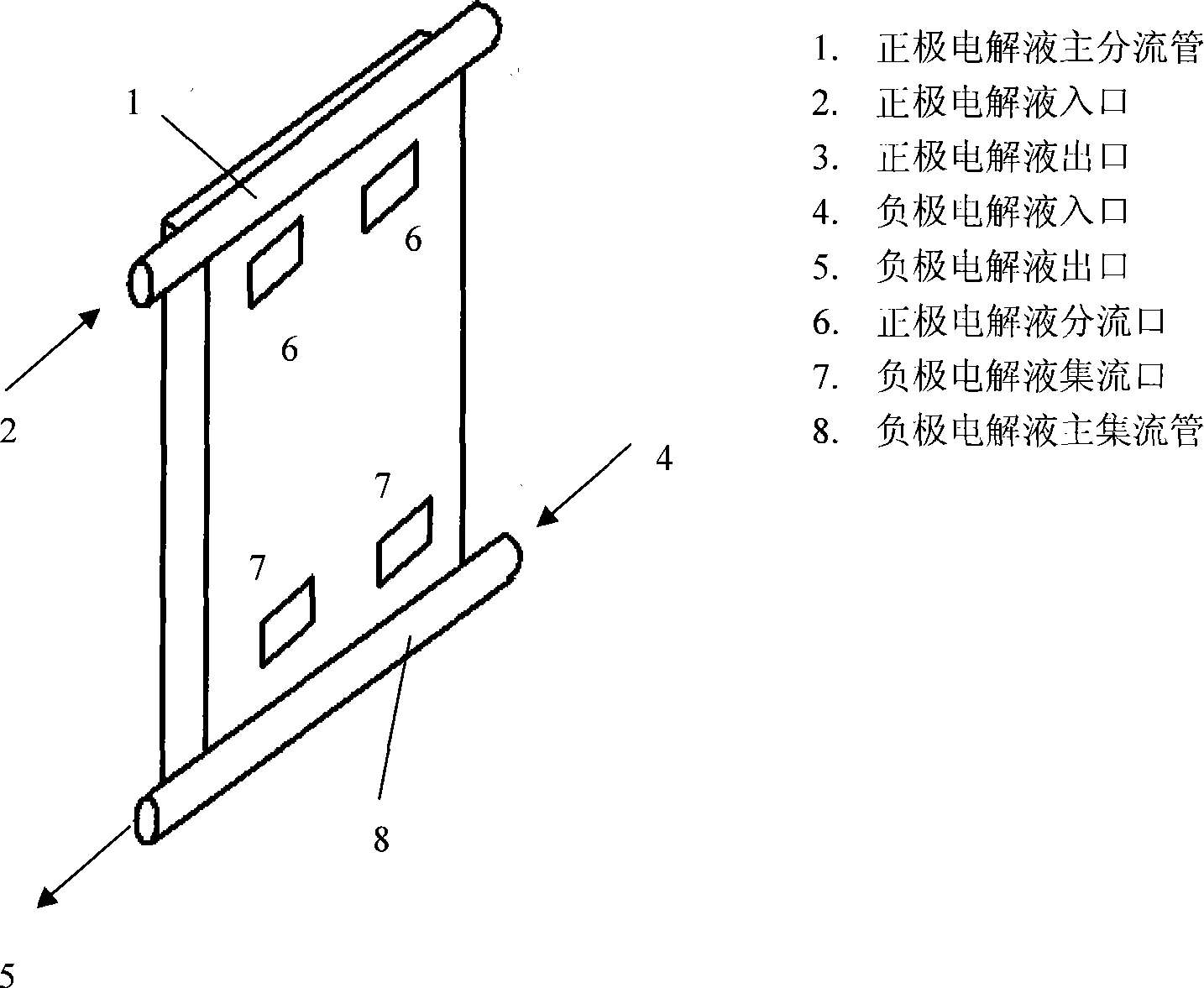

[0021] The all-vanadium redox flow battery stack is composed of four single cells in series, the effective electrode area is 200×270mm, and the positive and negative electrolytes are 800ml of 1.0mol / L V4++2mol / L H2SO4 and 1.0mol / L V3 respectively ++2mol / L H2SO4 aqueous solution, charge and discharge experiments were carried out at an electrolyte circulation flow rate of 50L / h, and the stack performance of the redox flow battery was measured at room temperature. Figure 4 is the curve of charging and discharging current and volta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com