Rubber composition, production method and shock-absorbing foot mat produced thereof

A technology of rubber composition and shock-absorbing feet, which is applied in the field of shock-absorbing foot pads, can solve the problems of cumbersome manufacturing steps, high rigidity of solid structures, and poor plastic friction resistance, and achieve simple and easy preparation methods, small sliding friction, Easy to move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

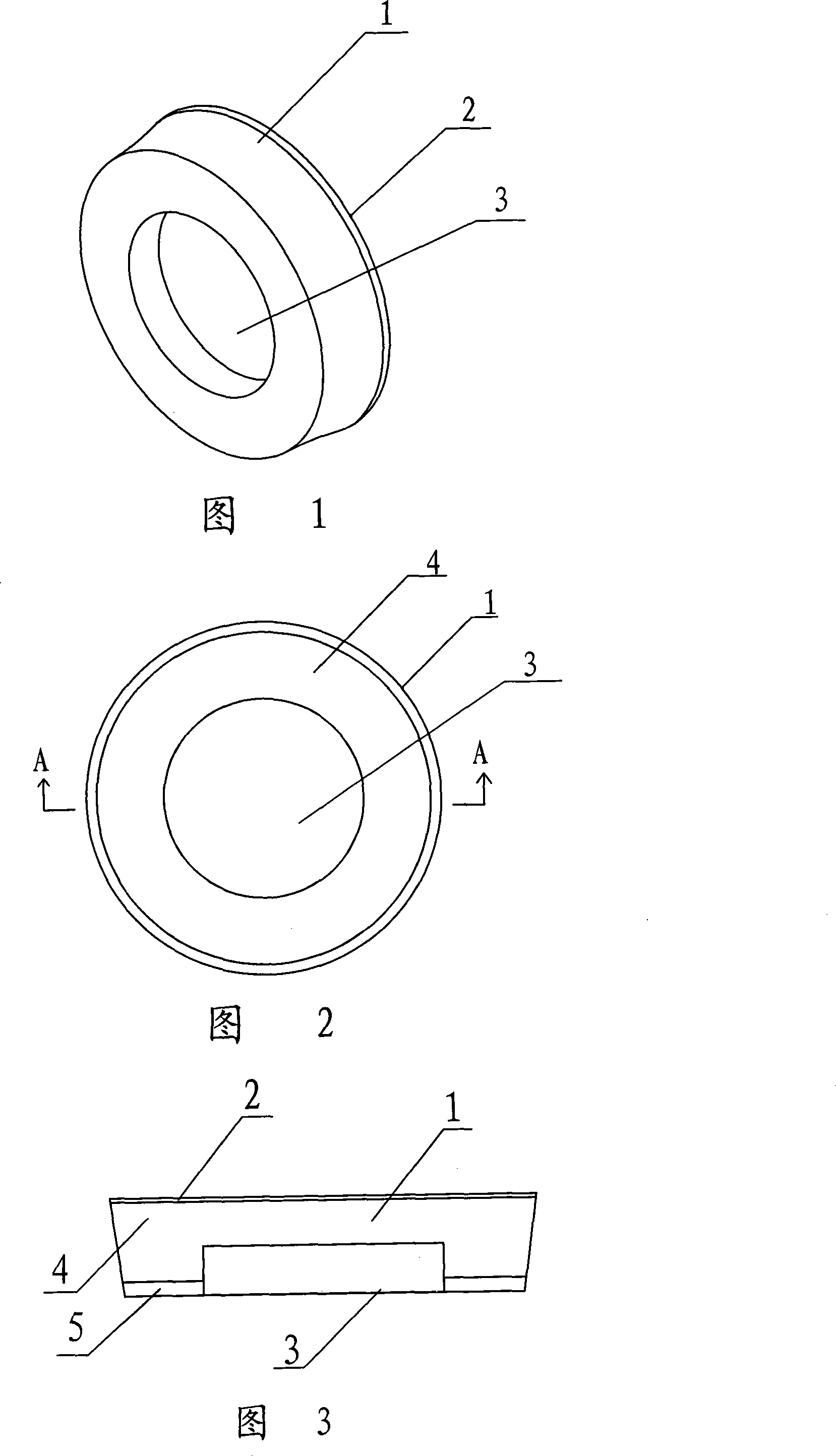

Image

Examples

Embodiment 1

[0025] Example 1: With reference to Table 1, a rubber composition comprising the following raw materials in parts by weight: 40-60% diene rubber, 30-50% reinforcing filler, 3-5% active agent, and vulcanizing agent 0.8-1.2%, vulcanization accelerator 0.7-2.0% and plasticizer 1-3%. Wherein, when the diene rubber is natural rubber and high benzene rubber, it constitutes a hard rubber composition. The reinforcing filler is one of ultrafine talc powder N330, high wear-resistant carbon black, light calcium, or any combination thereof; the active agent is one of zinc oxide, stearic acid, or A booster Any combination; the vulcanization accelerator is one of DM, D, TT, CZ, TT or ACP-300 or any combination thereof; the plasticizer is naphthenic oil. Specifically, refer to the components and weight ratios listed in column 3 of Table 1.

[0026] A method for preparing the aforementioned rubber composition, which includes the following steps: (1) Put the rubber into an open mill and mix it eve...

Embodiment 2

[0029] Example 2: A rubber composition and preparation method provided in this example are basically the same as Example 1. The difference is that the rubber composition includes the following raw materials in parts by weight: diene rubber 45 to 55%, reinforcing filler 35 to 45%, active agent 3.5 to 4.5%, vulcanizing agent 0.9 to 1.1%, vulcanization accelerator 0.8 to 1.5%, and plasticizer 2 to 3%. When the diene rubber is natural rubber and styrene butadiene rubber, it constitutes a soft rubber composition. Specifically, see the components and weight ratios listed in column 4 of Table 1.

[0030] The difference in its preparation method is that it includes the following steps: Take natural rubber (NR) and styrene butadiene rubber (SBR) in the ratio shown in Table 1 and put them in a mill with a roll pitch of 0.1mm wide, and mix, Put the uniformly plasticized compound rubber into the internal mixer, put in stearic acid after mixing for 2 minutes, put in zinc oxide after 20 seconds...

Embodiment 3

[0034] Example 3: A rubber composition, a preparation method and a shock-absorbing foot pad prepared in this example are basically the same as those in Example 1 or 2, except that the rubber composition includes the following weights The proportion of raw materials: 47% of diene rubber, 45% of reinforcing filler, 4.1% of active agent, 1.1% of vulcanizing agent, 0.8% of vulcanization accelerator, and 2% of plasticizer. Specifically, see the components and weight ratios listed in column 5 of Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com