Anti-rust defect detecting liquid and its preparing technique

A preservative, weight percentage technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of poor results and high cost of use, and achieve the effects of showing clear magnetic marks, avoiding pollution, and reducing flaw detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

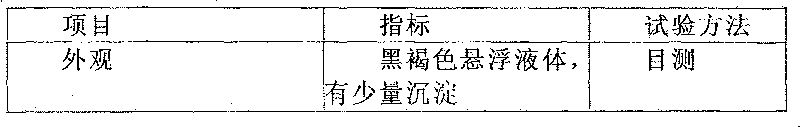

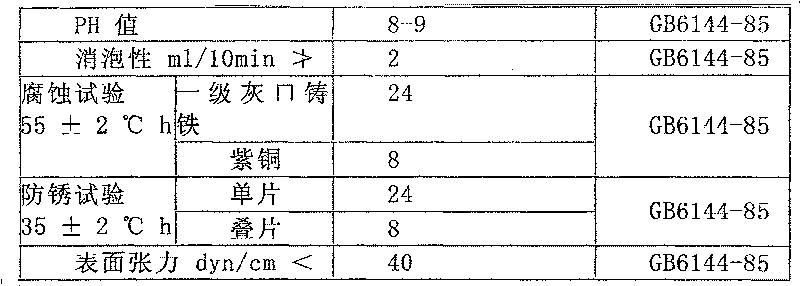

[0013] The components and weight percentages included in this anti-rust flaw detection solution are: 3.0% carboxylic ester; 15.0% polyalcohol; 0.5% non-ferrous metal preservative; 5.0% ionic surfactant; 5.0%; 20.0% dispersant; 5.0% magnetic adsorbent; 7.0% developer; 0.5% foam suppressor;

[0014] The carboxylic ester is the reaction product of triethanolamine and sebacic acid; the polyol is triethanolamine or diethanolamine; the non-ferrous metal preservative is thiadiazole or benzodiazepine; the ionic surface active The agent is NP-10 and Siben-80 or OP-10 and Siben-80; the dispersant is fatty alcohol and ethylene oxide condensate; the magnetic adsorbent is polar pigment or magnetic powder; The developer is silver bromide and sodium thiosulfate; the foam suppressor is simethicone. This anti-rust flaw detection fluid aims at the disadvantages of oil flaw detection fluid, it is a new type of water magnetic suspension flaw detection fluid, which is used for flaw detection of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com