Method for representing visible light solidifying performance of resin and adhesive for tooth material

A technology of dental materials and adhesives, applied in dental preparations, analytical materials, material inspection products, etc., can solve problems such as large data errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add white solid 4-META (4-ethoxy trimellitic anhydride) to liquid reactive diluent TEGDMA (triethylene glycol dimethacrylate) and matrix resin Bis-GMA (bisphenol A glycidyl methacrylate) ester) and stir evenly to obtain a binder mixture with a volume ratio of the three of 1:3:6.

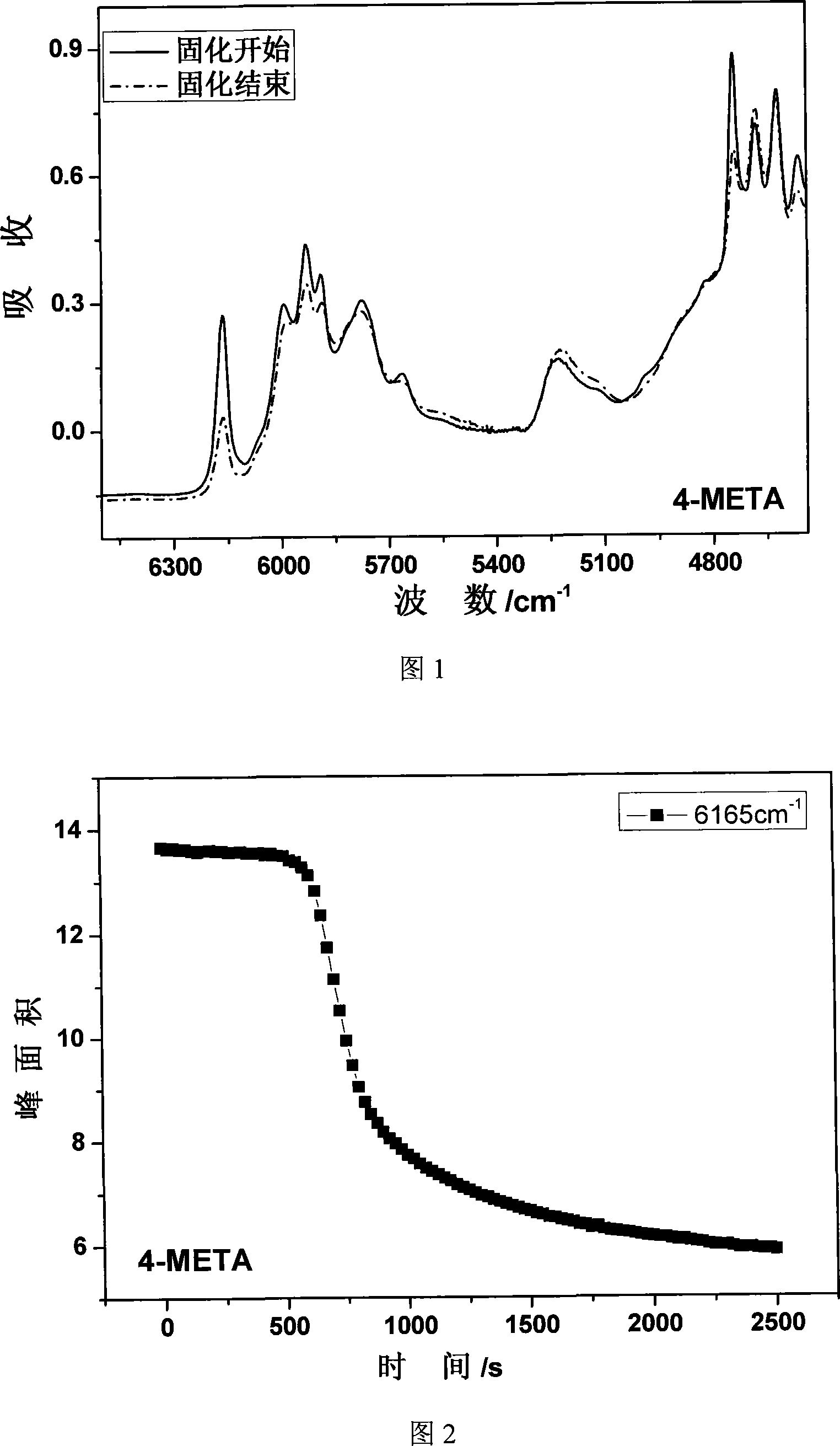

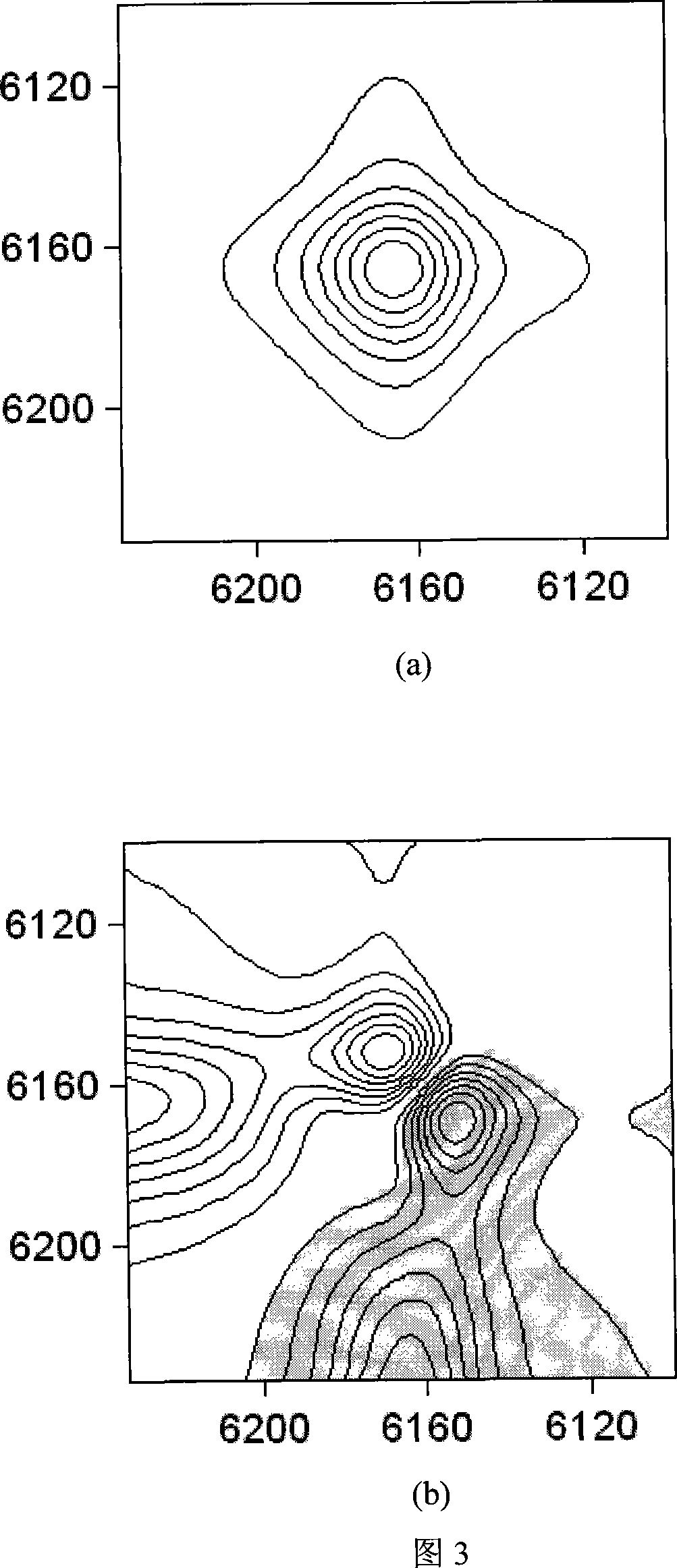

[0042] The adhesive is placed between two slides and placed in an infrared in situ cell at room temperature. Fix the visible light source, carry out continuous visible light curing on the adhesive, and conduct an online infrared test on the whole process, and obtain a series of infrared spectra. Figure 1 is the infrared spectra measured at the beginning of curing and the end of curing.

[0043] 6165cm in the infrared spectrum measured at different curing times -1 The peak area of the absorption peak is quantitatively analyzed and plotted (Fig. 2). Through Fig. 2, it can be calculated that the curing degree of the 4-META binder under visible light curing conditions is 56.91%. The specific m...

Embodiment 2

[0046] The liquid reactive diluent TEGDMA and the matrix resin Bis-GMA were stirred evenly to prepare a mixture with a volume ratio of 4:6.

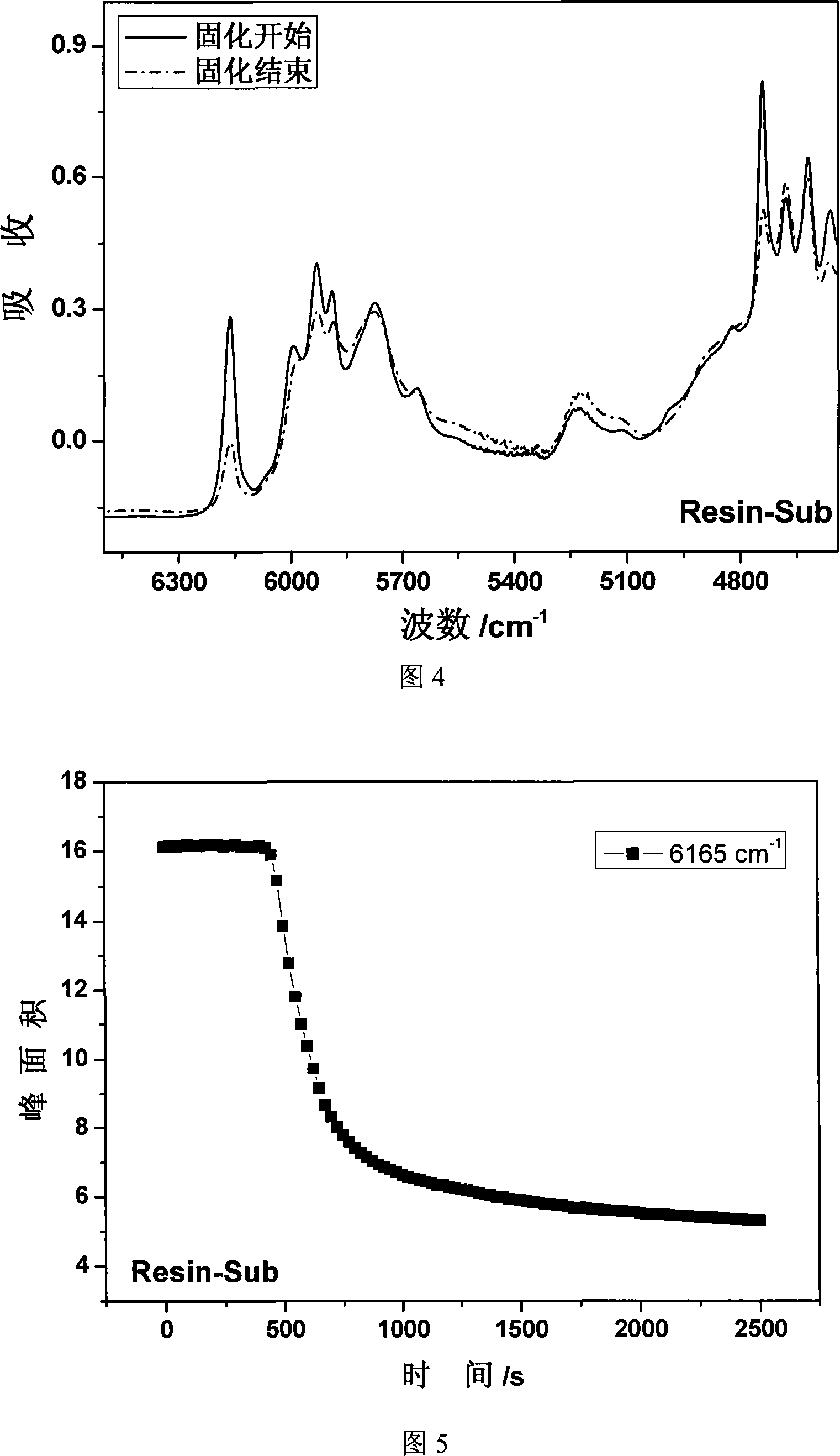

[0047] The mixture was placed between two slides in an infrared in situ cell at room temperature. The visible light source is fixed and the adhesive is continuously cured by visible light, and the online infrared test is carried out for the whole process, and a series of infrared spectra are obtained. Fig. 4 is the infrared spectrogram measured at the beginning of curing and the end of curing.

[0048] 6165cm in the infrared spectrum measured at different curing times -1 The peak area of the absorption peak is quantitatively analyzed and plotted (Fig. 5), and the degree of curing of the diluent TEGDMA and matrix resin Bis-GMA mixture under visible light curing conditions can be calculated to be 67.19%, and the specific calculation method is the same as in the embodiment 1; In addition, it can also be inferred that the curing inductio...

Embodiment 3

[0051] Add the white solid PMDM (ethoxy pyromellitate dimethacrylate) into the liquid reactive diluent TEGDMA and the matrix resin Bis-GMA and stir evenly to obtain a bond with a volume ratio of 1:3:6. agent mixture.

[0052] The adhesive is placed between two slides and placed in an infrared in situ cell at room temperature. The visible light source is fixed and the adhesive is continuously cured by visible light, and the online infrared test is carried out for the whole process, and a series of infrared spectra are obtained. Fig. 7 is the infrared spectrogram measured at the beginning of curing and the end of curing.

[0053] 6165cm in the infrared spectrum measured at different curing times -1 The peak area of the absorption peak is quantitatively analyzed and plotted (Fig. 8), and the degree of curing of the PMDM adhesive under visible light curing conditions can be calculated to be 55.73% by Fig. 8; The curing induction period under the experimental curing conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com