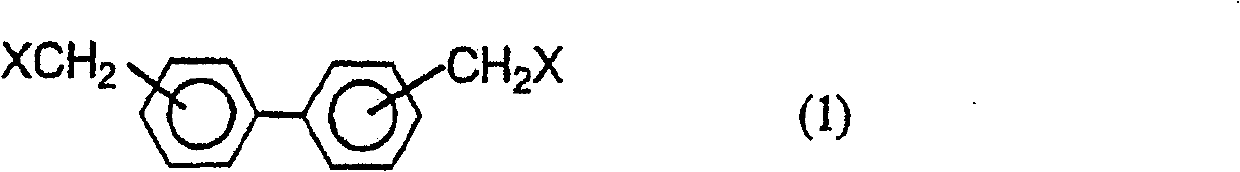

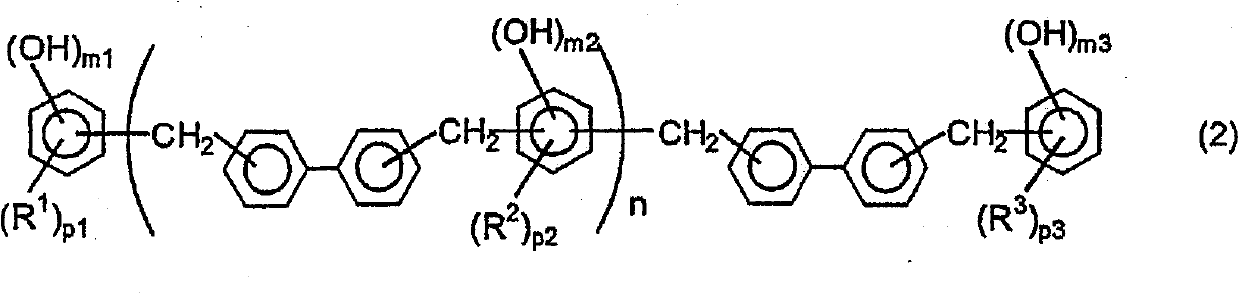

Biphenylene-bridged phenol novolak resins and use thereof

A novolac resin and biphenyl technology, which is applied in the field of biphenylene cross-linked novolac resins, can solve the problems of slow curing speed, long curing time, adverse effects on productivity or production cost, etc., and achieves low water absorption. sex, improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

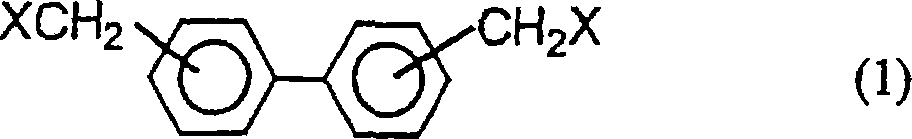

[0053] 169.2 parts (1.8 moles) of phenol, 22 parts (0.2 moles) of catechol, 112.6 parts (0.465 moles) of 4,4'-bismethoxymethylbiphenyl and 0.10 parts of 50% by weight sulfuric acid. Under nitrogen flow, the reaction was carried out at an internal temperature of 110°C to 140°C for 3 hours, then at 165°C for 3 hours, and cooled to 95°C. After cooling, 250 parts of pure water of 90° C. or higher were added and washed with water. Then, the internal temperature was raised to 160° C., and unreacted components were removed by decompression-steam treatment. A resin having a softening point of 65.3°C was obtained. As analyzed by gel permeation chromatography (hereinafter referred to as GPC), the polystyrene-equivalent number average molecular weight (Mn) was 773, and the weight average molecular weight (Mw) was 920.

Embodiment 2

[0055] 169.2 parts (1.8 moles) of phenol, 22 parts (0.2 moles) of resorcinol, 112.6 parts (0.465 moles) of 4,4'-bismethoxymethylbiphenyl and 0.10 parts of 50% by weight sulfuric acid. Under nitrogen flow, the reaction was carried out at an internal temperature of 110°C to 140°C for 3 hours, then at 165°C for 3 hours, and cooled to 95°C. After cooling, 250 parts of pure water of 90° C. or higher were thrown in and washed with water. Then, the internal temperature was raised to 160° C., and unreacted components were removed by decompression-steam treatment. A resin having a softening point of 78.8°C was obtained. By GPC analysis, the number average molecular weight (Mn) in terms of polystyrene was 858, and the weight average molecular weight (Mw) was 1116.

Embodiment 3

[0057] 169.2 parts (1.8 moles) of phenol, 22 parts (0.2 moles) of hydroquinone, 112.6 parts (0.465 moles) of 4,4'-bismethoxymethylbiphenyl and 0.10 parts of 50% by weight sulfuric acid. Under nitrogen flow, the reaction was carried out at an internal temperature of 110°C to 140°C for 3 hours, then at 165°C for 3 hours, and cooled to 95°C. After cooling, 250 parts of pure water of 90° C. or higher were thrown in and washed with water. Then, the internal temperature was raised to 160° C., and unreacted components were removed by decompression-steam treatment. A resin having a softening point of 70.6°C was obtained. By GPC analysis, the number average molecular weight (Mn) was 778 and the weight average molecular weight (Mw) was 930 in terms of polystyrene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com