Method for purifying liquid crystal material

A liquid crystal material and electric field technology, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problem of not being able to increase the resistivity of liquid crystal materials stably and effectively, and achieve the effect of small influence, good reproducibility, and low loss of liquid crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This example is used to illustrate the method for purifying liquid crystal material provided by the present invention.

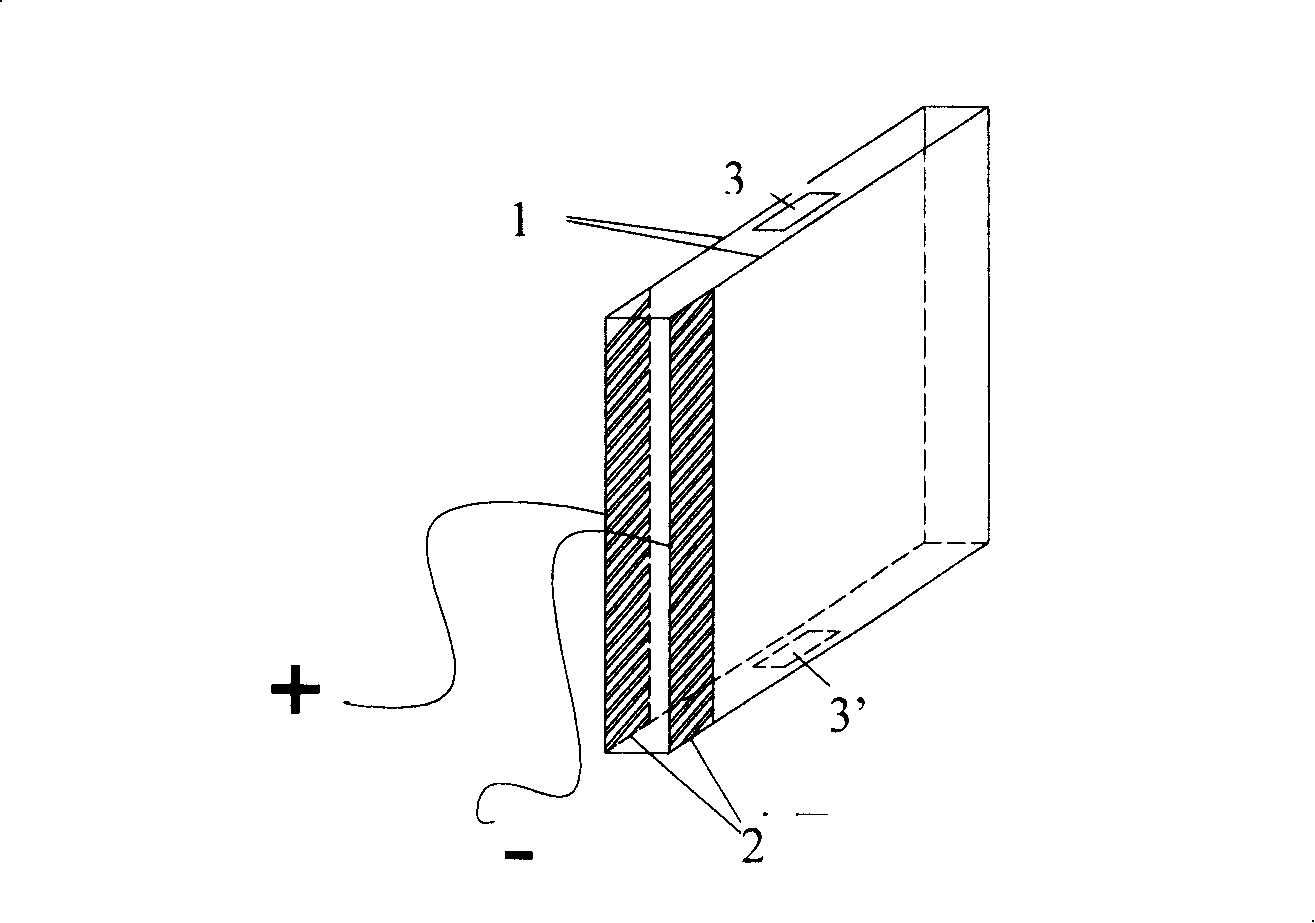

[0022] The initial resistivity was reduced to 3.0×10 by the pressurization method using a vacuum pump 11 2 liters of 4-(trans-4'-propylcyclohexyl) cyanide monomer liquid crystal in ohm cm was injected into an indium tin oxide conductive glass cell (CSG) with a length of 1.5 meters, a width of 0.5 meters and a height of 1000 microns Produced by the company), apply a DC voltage of 200 volts on the two pieces of conductive glass of the conductive glass box, control the injection speed of the monomer liquid crystal to 1 liter / 6 hours, and receive the purified liquid crystal material at the outlet of the conductive glass box , to obtain a resistivity of 1.99 liters of 6.3×10 13 ohm-cm liquid crystal material.

Embodiment 2

[0024] This example is used to illustrate the method for purifying liquid crystal material provided by the present invention.

[0025] The initial resistivity was reduced to 4.0×10 by the pressurization method using a vacuum pump 12 2 liters of 4-(trans-4'-propylcyclohexyl) cyanide monomer liquid crystal in ohm cm was injected into an indium tin oxide conductive glass cell (CSG) with a length of 1.5 meters, a width of 0.5 meters and a height of 1000 microns (manufactured by the company), apply a DC voltage of 280 volts on the two pieces of conductive glass of the conductive glass box, control the injection speed of the monomer liquid crystal to 0.5 liters / 6 hours, and receive the purified liquid crystal material at the outlet of the conductive glass box , to obtain a resistivity of 1.99 liters of 6.8×10 13 ohm-cm liquid crystal material.

Embodiment 3

[0027] This example is used to illustrate the method for purifying liquid crystal material provided by the present invention.

[0028] The initial resistivity was reduced to 4.0×10 by the pressurization method using a vacuum pump 12 2 liters of 4-(trans-4'-propylcyclohexyl) cyanide monomer liquid crystal in ohm cm was injected into an indium tin oxide conductive glass cell (CSG) with a length of 1.5 meters, a width of 0.5 meters and a height of 1000 microns (manufactured by the company), apply a DC voltage of 180 volts on the two pieces of conductive glass in the conductive glass box, control the injection speed of the monomer liquid crystal to 0.8 liters / 6 hours, and receive the purified liquid crystal material at the outlet of the conductive glass box , to obtain a resistivity of 1.99 liters of 6.4×10 13 ohm-cm liquid crystal material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com