Surface treatment method for hydrogen-storing alloy powder

A technology of surface treatment and alloy powder, applied in the field of surface treatment of hydrogen storage alloy powder, can solve the problems of high current discharge performance and poor low temperature discharge performance, and achieve the effect of good low temperature discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example illustrates the surface treatment method of the hydrogen storage alloy powder provided by the present invention.

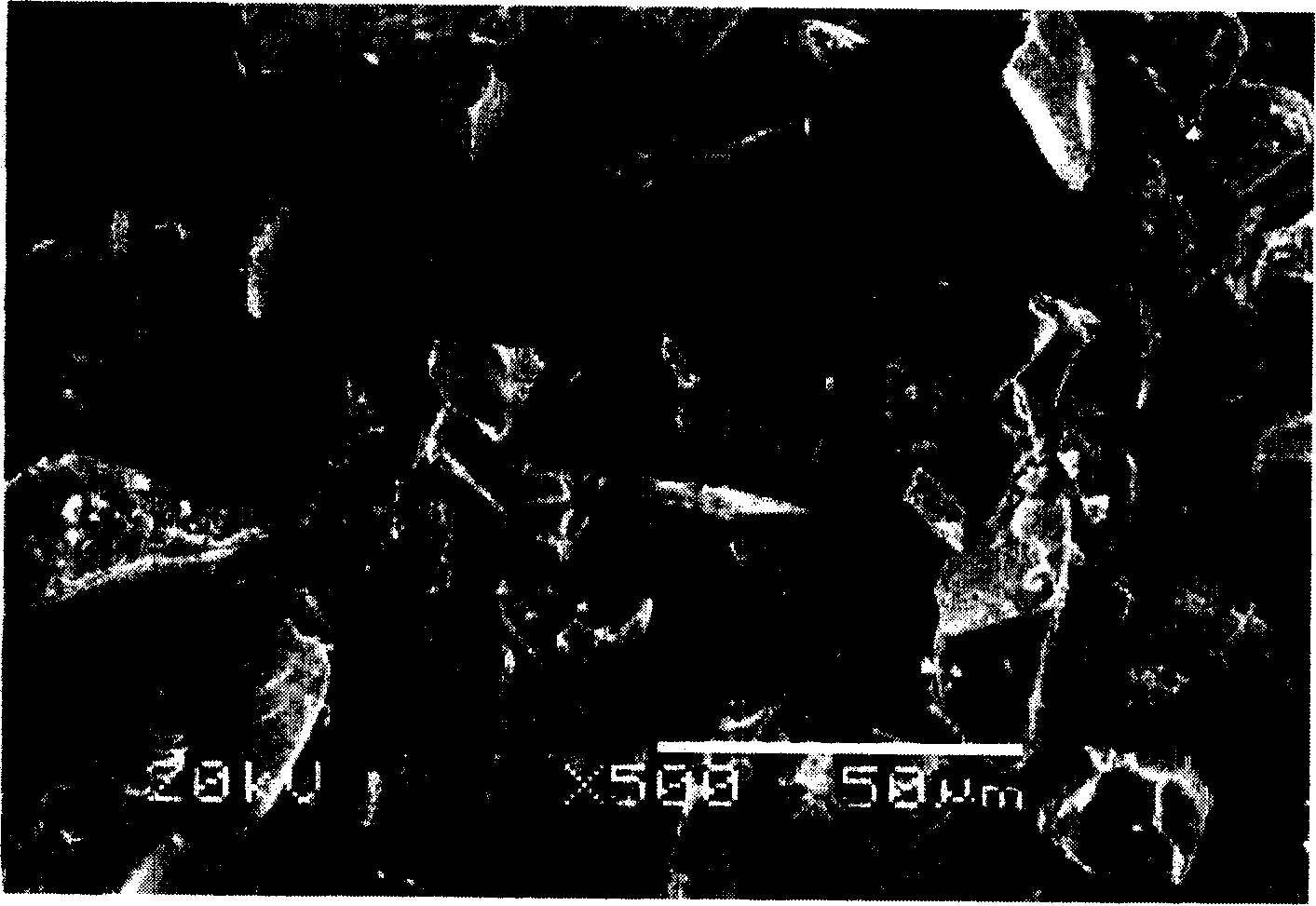

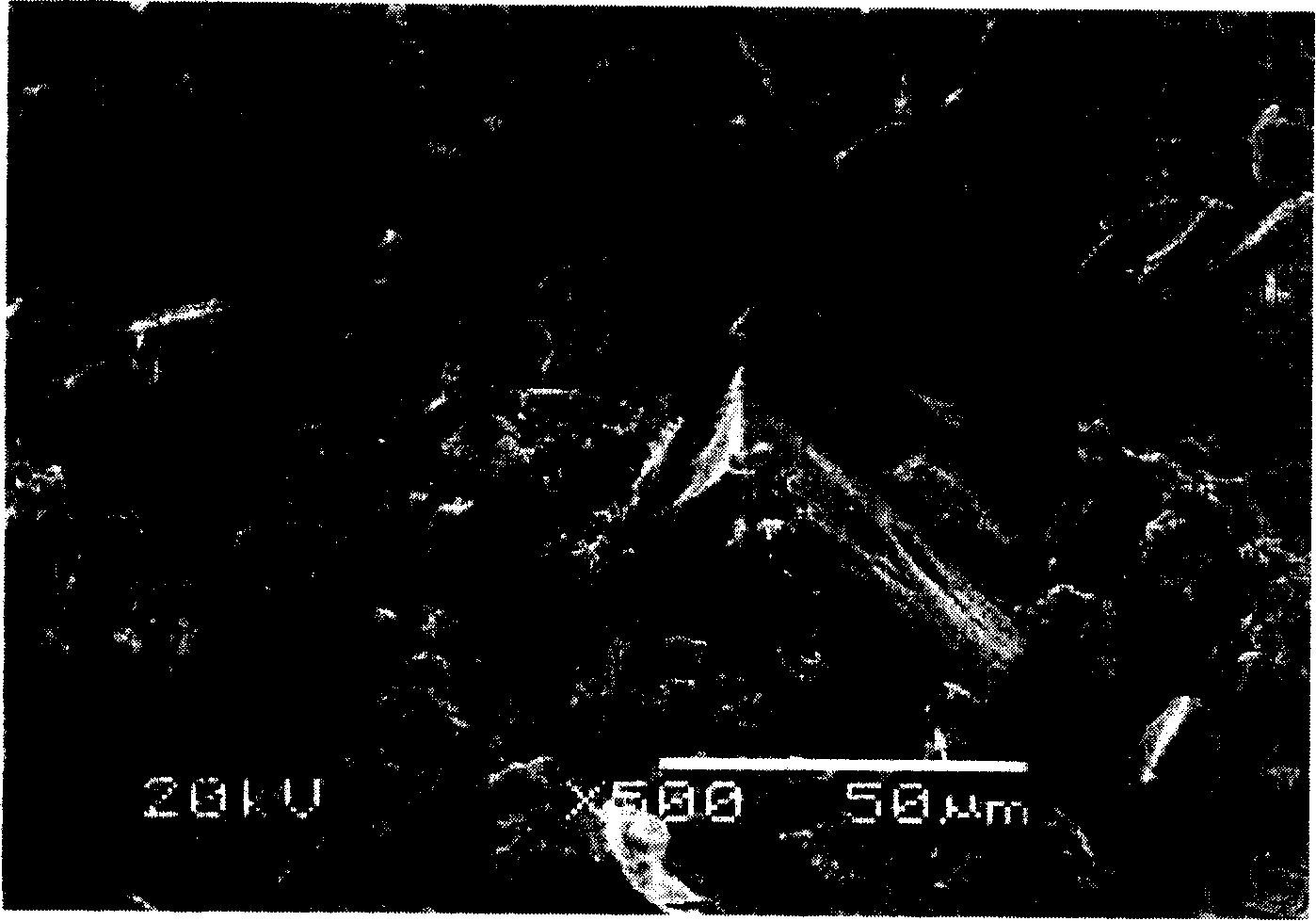

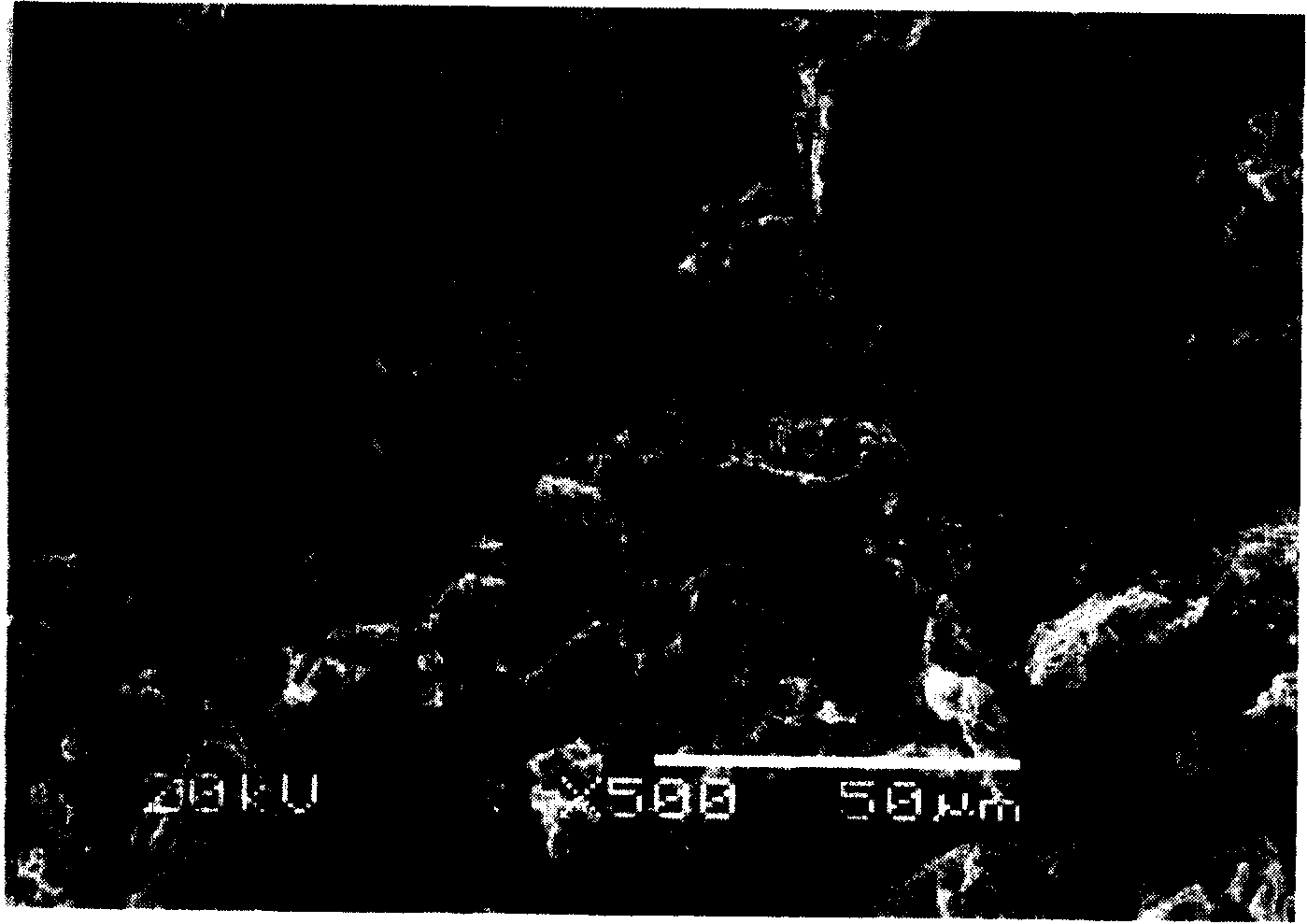

[0027] 800 grams of alloy powder (Xiamen Tungsten Industry, MM03200, magnified 500 times by scanning electron microscope) shows the surface morphology figure 1 Shown) join in 2 liters of cobaltous sulfate aqueous solution, the content of the cobaltous sulfate in described cobaltous sulfate aqueous solution is 0.25% by weight, then add 8 grams of sodium hypophosphite, mix under stirring for 30 minutes, use Bühner funnel The solid matter was separated by suction filtration, spread the solid matter on a clean and dry plane with a thickness of about 10 mm, and stood in the air for 24 hours. Then this alloy powder is placed in 0.5 liters of sodium hydroxide solution, the concentration of described sodium hydroxide solution is 5 mol / liter, temperature is 80 ℃, contacts under stirring for 30 minutes, obtains solid matter with Buchner funnel suction fi...

Embodiment 2

[0032] The alloy powder was processed according to the method of Example 1, except that the content of cobaltous sulfate in the cobaltous sulfate aqueous solution was 0.5% by weight, and then 12 grams of sodium hypophosphite was added. The oxidation was carried out in an oxygen atmosphere for 5 hours. Alloy powder A2 was prepared.

Embodiment 3

[0034] The alloy powder is processed according to the method of Example 1, and the difference is that the cobaltous salt aqueous solution is a cobaltous chloride aqueous solution, and the content of the cobaltous chloride in the cobaltous chloride aqueous solution is 0.3% by weight, and then 15 grams of potassium hypophosphite. Alloy powder A3 was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com