Proton exchange membrane fuel cell structure applicable to high temperature operation

A proton exchange membrane and fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problems of liquid water remaining and increasing system complexity, achieve volume reduction, and facilitate mass production , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the technical solution of the present invention, the structure of the membrane electrode bipolar plate assembly according to the present invention will be further described below in conjunction with the accompanying drawings.

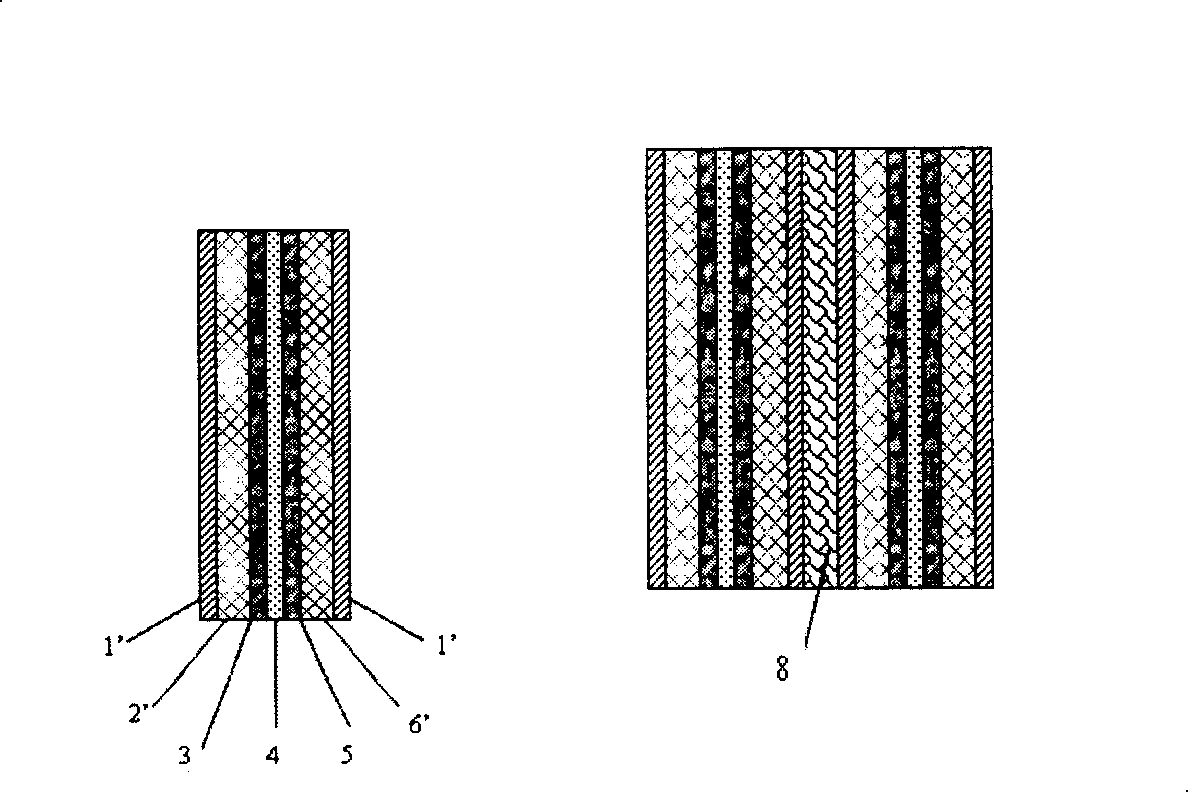

[0018] Such as figure 1 Shown:

[0019] Carbon felt, stainless steel fiber felt, titanium foam, metal fine wire mesh, etc. or specially designed porous microchannels are used as the flow field and the diffusion layer (fuel flow field 2', oxidant flow field 6'), attached to the thin metal separator On the separator (thin metal separator 1'), proton exchange membrane 4 with electrodes (anode electrode 3, cathode electrode 5) constitutes a membrane electrode bipolar plate assembly. It forms a single battery with the cooling cavity 8 .

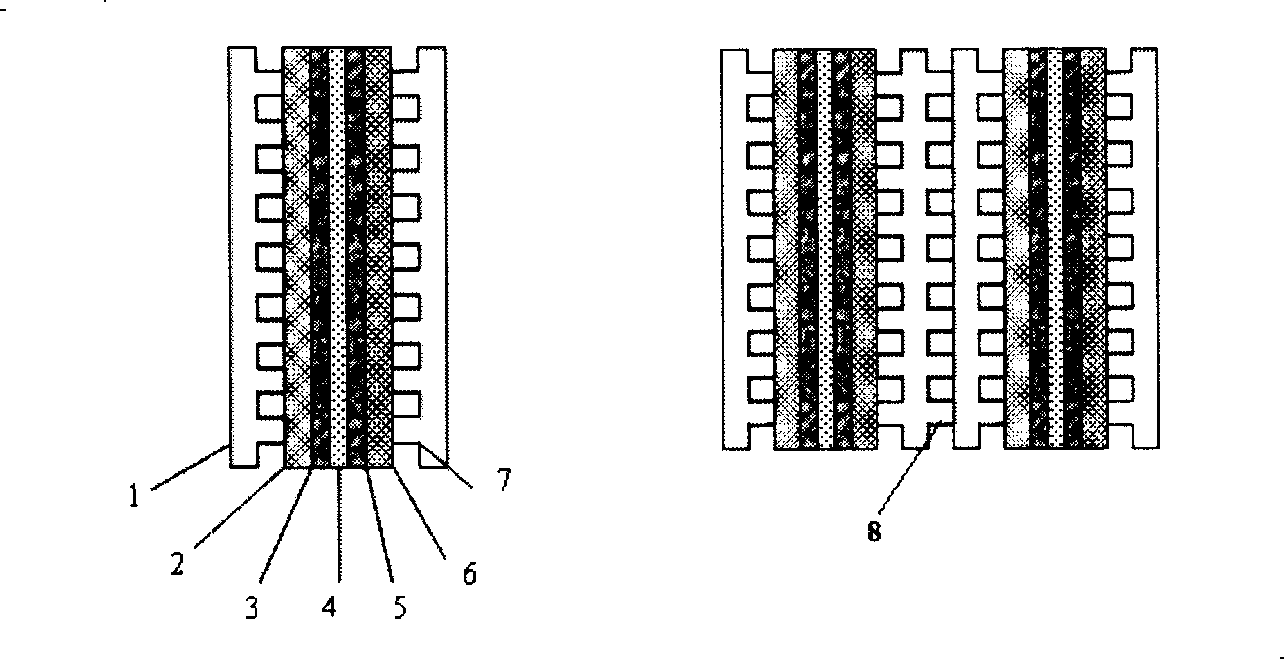

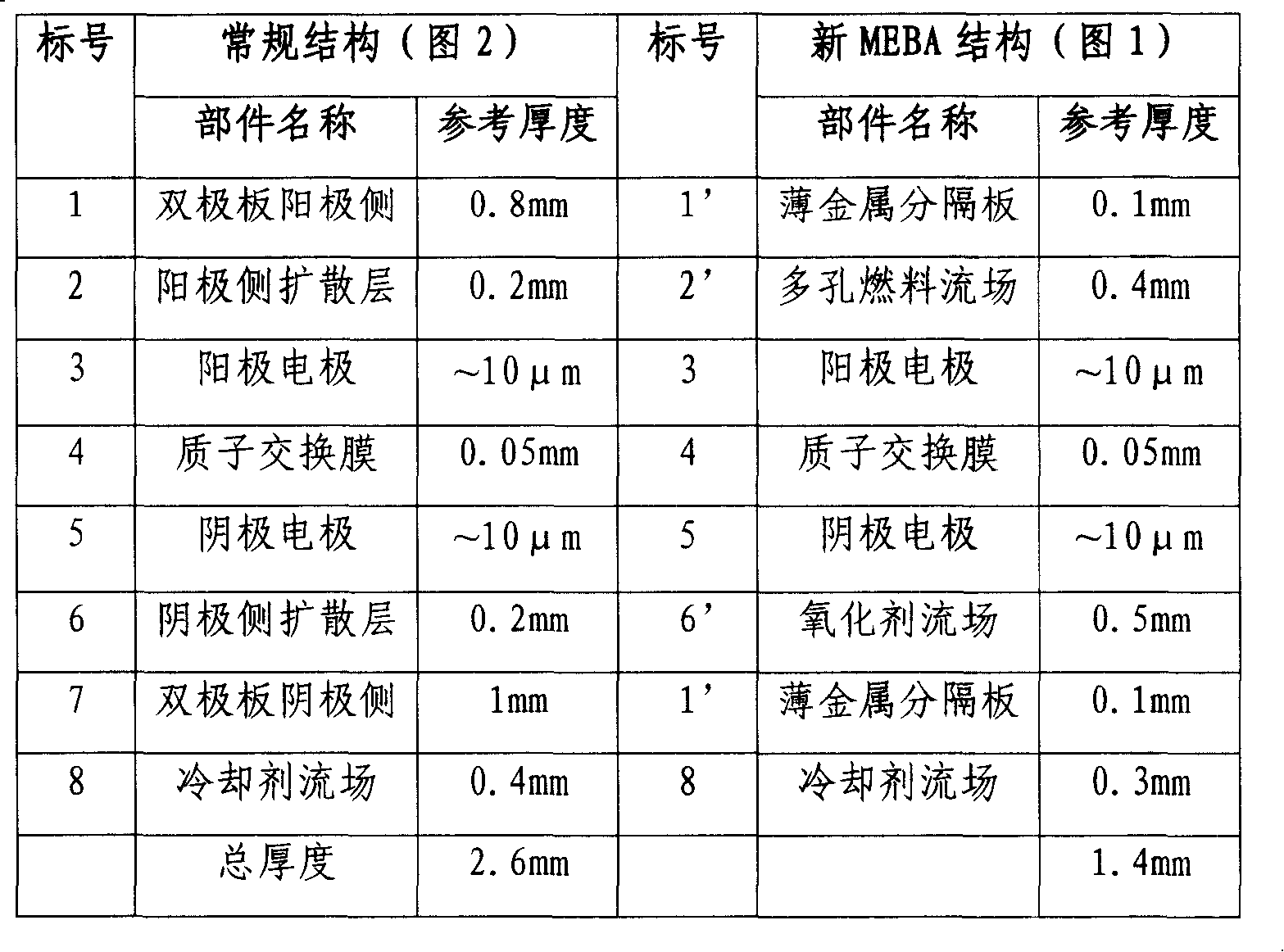

[0020] Due to the simplified structure, the thickness is greatly reduced. The comparison of new structure of the present invention and conventional structure is shown in the table bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com