Video frequency reinforcing reality auxiliary operation welding protection helmet

A technology for video enhancement and auxiliary operation, applied in ophthalmic surgery, goggles, etc., can solve the problems of difficulty in meeting the requirements of high-tech welding product quality, accuracy and efficiency, welding workpiece assembly errors, etc., to improve welding quality, convenient operation, high-tech effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below by accompanying drawing:

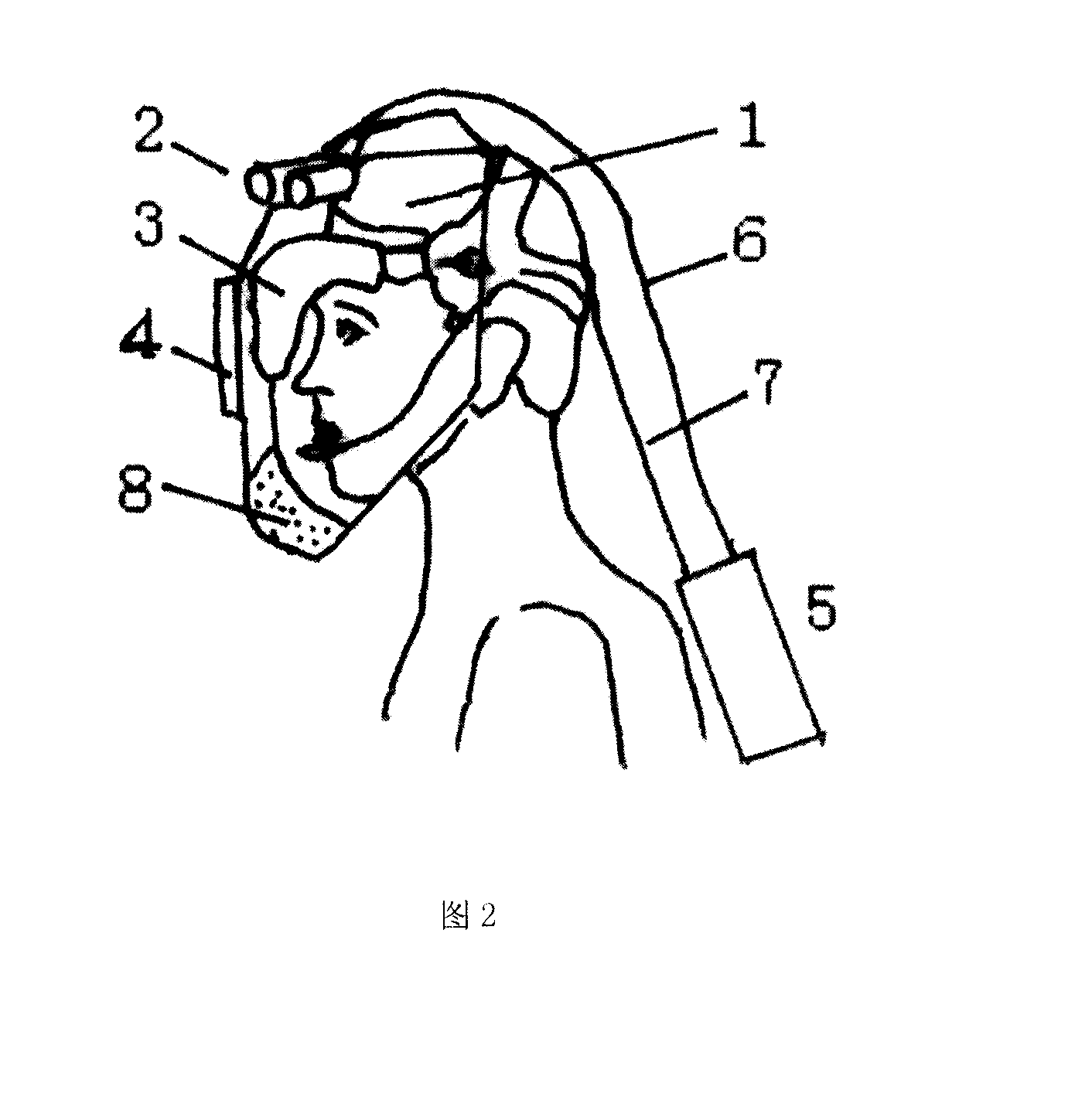

[0020] Figure 1 is a schematic diagram of video augmented reality. The real-world images are captured by two cameras installed on the user's helmet, and the computer calculates and processes these images, superimposes the information to be added on the video signal of the camera, and realizes the alignment of the virtual scene and the real scene through video signal fusion , and finally presented to the user through a display system similar to a virtual reality immersive head-mounted display. Since the user's eyes do not directly see the real world, the position and direction of the camera represent the position and line-of-sight direction of the user's head.

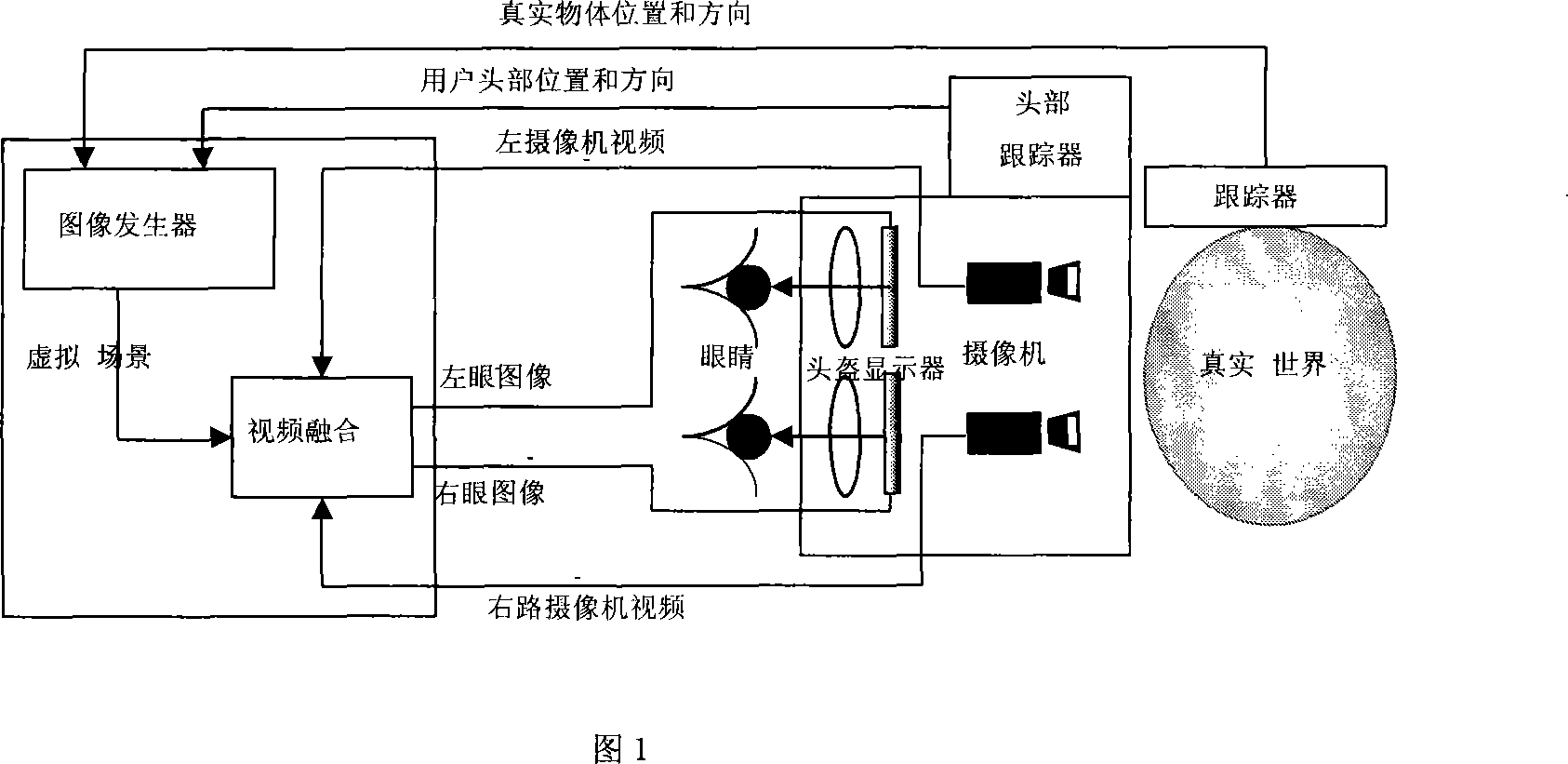

[0021] Figure 2 is a sketch of the helmet structure. It consists of a welding protective helmet 1, a camera 2, a helmet display 3, video input and output devices 6, 7, a portable computer 5, protective glass 4, a fan, a microp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com