A kind of production method of straw decomposed fertilizer of leguminous crops

A technology of straw decomposing and production method, which is applied in the preparation of organic fertilizers, organic fertilizers, and fertilization devices, etc., to achieve the effects of avoiding environmental pollution and reducing the application amount of chemical fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

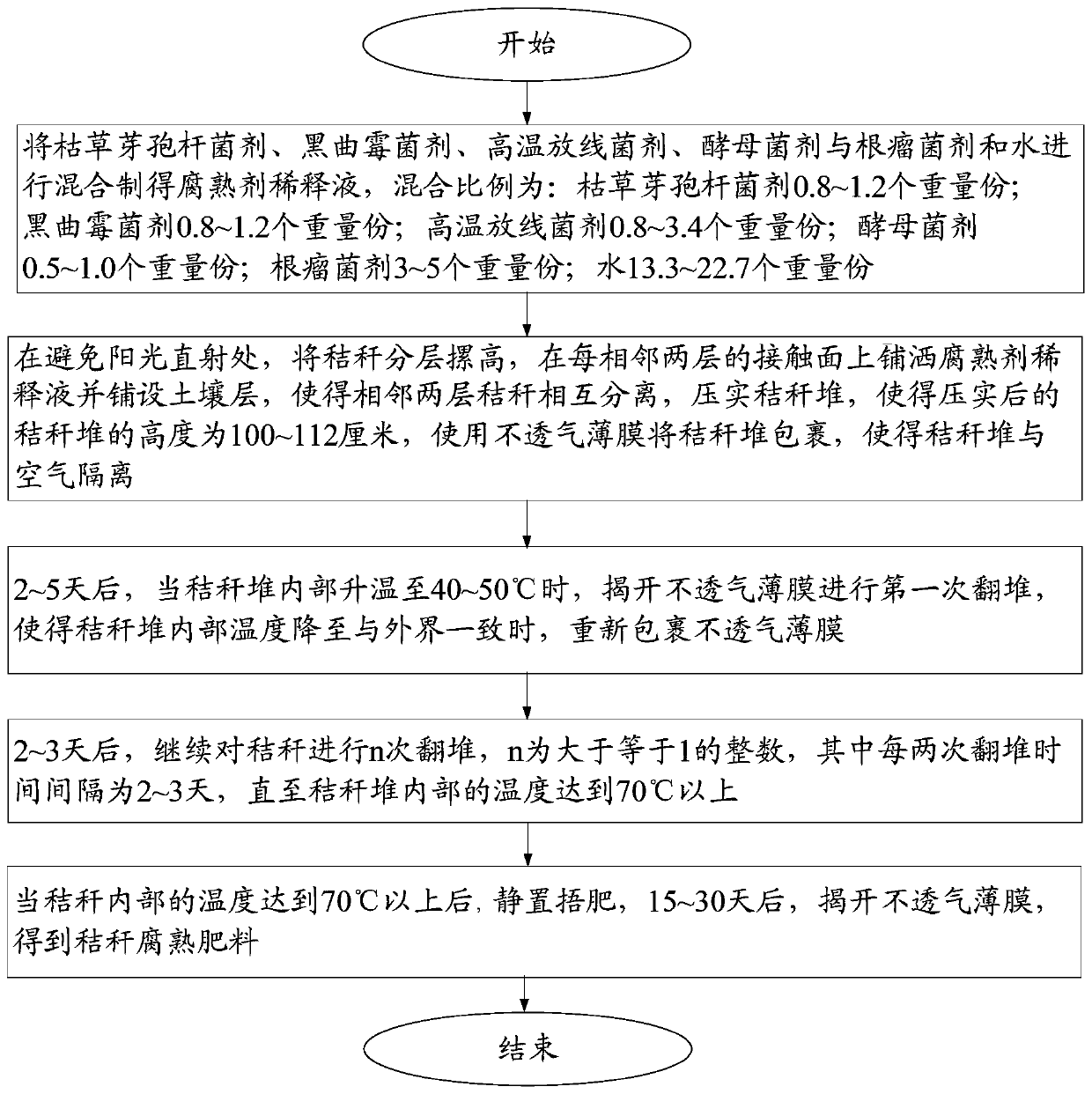

Image

Examples

Embodiment 1

[0026] Experimental Materials : straw

[0027] Experimental procedure :

[0028] (1) Bacillus subtilis agent, Aspergillus niger agent, high-temperature actinomycetes agent, saccharomyces agent are mixed with rhizobia agent and water to obtain decomposing agent dilution, and the mixing ratio is: 0.8 parts by weight of Bacillus subtilis agent 0.8 parts by weight of Aspergillus niger agent; 3.4 parts by weight of high-temperature actinomycetes agent; 0.5 parts by weight of yeast agent; 3 parts by weight of rhizobia agent; 13.3 parts by weight of water.

[0029] (2) Divide the stalks into 5 layers in a place where direct sunlight is avoided, spread decomposing agent dilution on the contact surface of each adjacent two layers and lay the soil layer, so that the adjacent two layers of straw are separated from each other, wherein, The dosage ratio of the decomposing agent dilution on the contact surface of each adjacent two layers is 3:2:2:3; the thickness of the soil layer is 8...

Embodiment 2

[0036] Experimental Materials : straw

[0037] Experimental procedure :

[0038] (1) Bacillus subtilis agent, Aspergillus niger agent, high-temperature actinomycetes agent, saccharomyces agent are mixed with rhizobia agent and water to obtain decomposing agent dilution, and the mixing ratio is: 0.8 parts by weight of Bacillus subtilis agent 0.8 parts by weight of Aspergillus niger agent; 2.0 parts by weight of high-temperature actinomycetes agent; 0.5 parts by weight of yeast agent; 5 parts by weight of rhizobia agent; 22.7 parts by weight of water.

[0039] (2) Divide the stalks into 5 layers in a place where direct sunlight is avoided, spread decomposing agent dilution on the contact surface of each adjacent two layers and lay the soil layer, so that the adjacent two layers of straw are separated from each other, wherein, According to the order from top to bottom, the amount of corrosive diluent on the contact surface of each adjacent two layers is 0.06kg / m 2 、0.04kg / m...

Embodiment 3

[0046] Experimental Materials : straw

[0047] Experimental procedure :

[0048] (1) Bacillus subtilis agent, Aspergillus niger agent, high-temperature actinomycetes agent, saccharomyces agent and rhizobia agent and water are mixed to obtain decomposing agent dilution, and the mixing ratio is: 0.9 parts by weight of Bacillus subtilis agent 0.9 parts by weight of Aspergillus niger agent; 1.5 parts by weight of high-temperature actinomycetes agent; 0.7 parts by weight of yeast agent; 4 parts by weight of rhizobia agent; 17.1 parts by weight of water.

[0049] (2) Divide the stalks into 5 layers in a place where direct sunlight is avoided, spread decomposing agent dilution on the contact surface of each adjacent two layers and lay the soil layer, so that the adjacent two layers of straw are separated from each other, wherein, According to the order from top to bottom, the amount of corrosive diluent on the contact surface of each adjacent two layers is 0.12kg / m 2 、0.08kg / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com