Method for refining lac red coloring matter

A technology of shellac red pigment and refining method, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve problems such as shortening process, environmental pollution, etc., and achieve obvious refining effect, improve safety, and eliminate pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

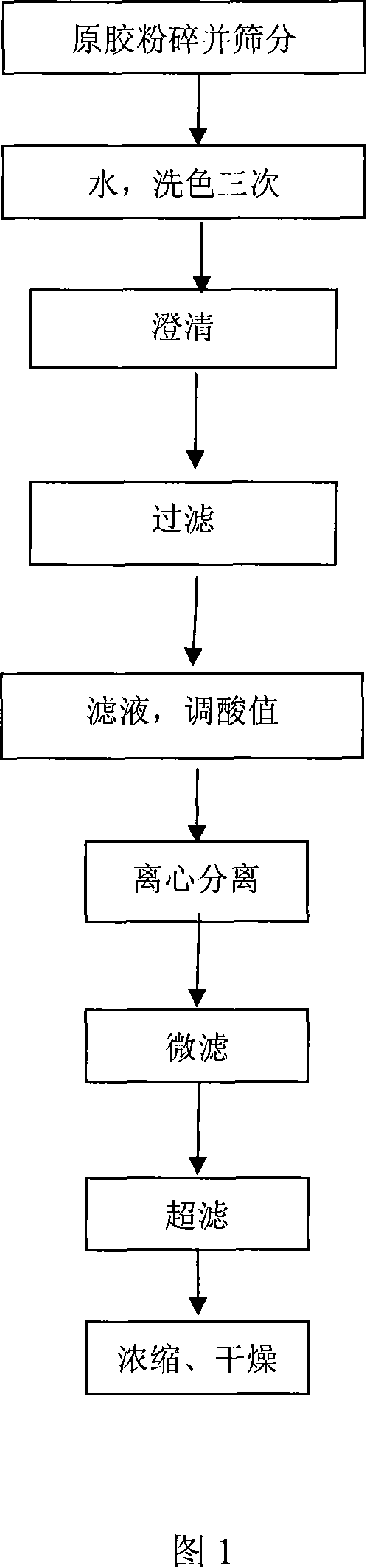

Method used

Image

Examples

Embodiment 1

[0044] 1. The raw rubber is crushed into particles with a particle size of 4-6 mm, and impurities such as resin, sand and soil are removed through a circular pendulum sieve;

[0045] 2. Add the crushed raw gum particles into a gum washing tank containing industrial tap water with a pH value between 7 and 8, and control the gum-to-liquid ratio (that is, the weight ratio of the crushed raw gum to the weight of the aqueous solution) at 1:5, Soak for 4 hours to collect the gel washing liquid; repeat three times and combine the gel washing liquid;

[0046] 3. Put the gel washing liquid into the clarification tank to settle, separate the sand and the fine shellac, the settlement time is 12 hours;

[0047] 4. The clarified washing liquid is filtered in two stages, the filter screen of the first filter is 200 mesh stainless steel wire mesh, and the filter of the second filter is 400 mesh stainless steel wire mesh;

[0048] 5. Use citric acid (solid) to adjust the acid value of the filtrate...

Embodiment 2

[0055] 1. Crush the raw rubber into particles with a particle size of 1 to 4 mm, and remove impurities such as resin and sand through a vibrating screen;

[0056] 2. Put the crushed raw rubber particles into a washing tank containing industrial tap water with a pH value of between 7 and 8, control the ratio of glue to liquid to 1:8, soak for 12 hours to collect the washing liquid; repeat three times and combine the washing liquid;

[0057] 3. Put the gel washing liquid into the clarification tank to settle, and separate the sand and fine shellac. The clarification time is 24 hours;

[0058] 4. Two-stage filtration of the clarified washing liquid, the first-stage filter is a 200-mesh stainless steel wire mesh, and the second-stage filter is a 400-mesh stainless steel wire mesh;

[0059] 5. Use phytic acid solution with a weight concentration of 3% to adjust the acid value of the filtrate, and control the pH of the filtrate to be 3.5-4.0;

[0060] 6. Feed the phytic acid-adjusted fi...

Embodiment 3

[0064] 1. Crush the raw rubber into particles with a particle size of 7-10 mm, and remove resin, sand and other impurities through a circular pendulum screen;

[0065] 2. Put the crushed raw rubber particles into a washing tank containing industrial tap water with a pH value of 7 to 8, control the ratio of glue to liquid to 1:3, soak for 2 hours to collect the washing liquid; repeat three times and combine the washing liquid;

[0066] 3. Put the gel washing liquid into the clarification tank to settle, separate the sand and the fine shellac, and the clarification time is 2 hours;

[0067] 4. The clarified washing liquid is filtered in two stages, the filter screen of the first filter is 200 mesh stainless steel wire mesh, and the filter of the second filter is 400 mesh stainless steel wire mesh;

[0068] 5. Adjust the acid value of the filtrate with an acetic acid solution with a weight concentration of 5%, and control the pH of the filtrate to 3.5-4.0;

[0069] 6. The filtrate ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com