Multi-component metal oxide semiconductor mesoporous material and synthesizing method thereof

A technology of oxide semiconductor and multi-element metal, which is applied in the field of synthesis of multi-element metal oxide semiconductor mesoporous materials, can solve the problems of small specific surface area of samples, harsh synthesis conditions, poor crystallinity, etc. The method is simple, the protection does not collapse, Effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

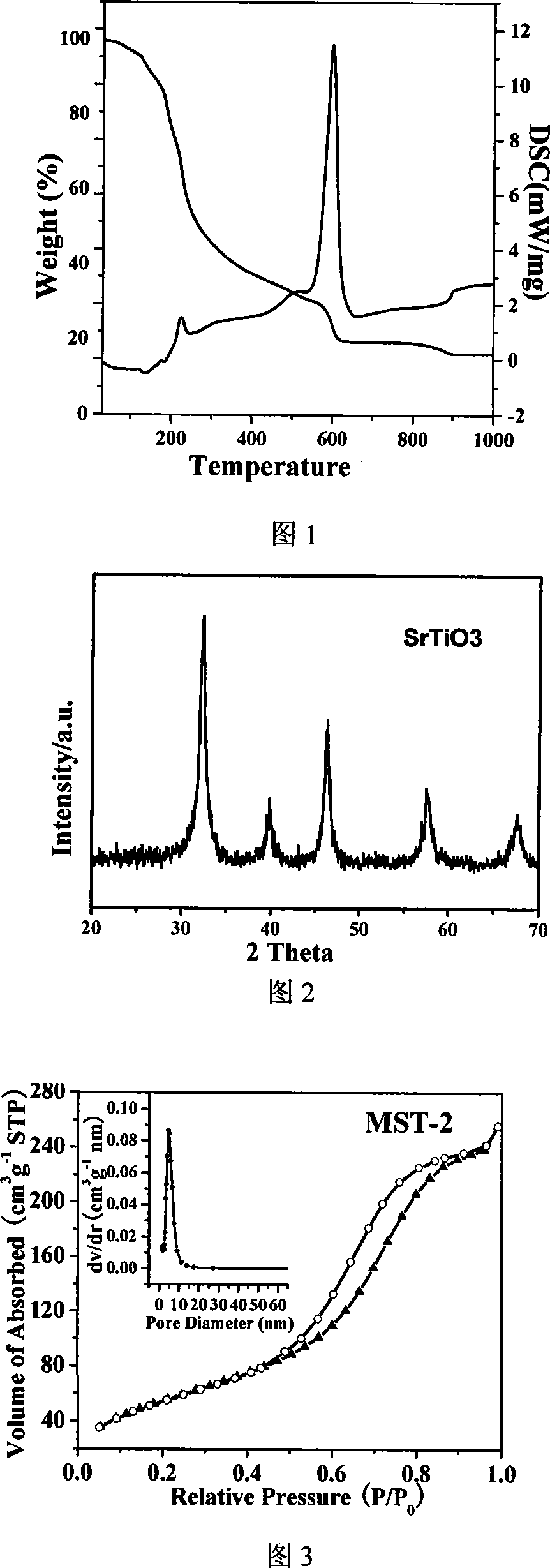

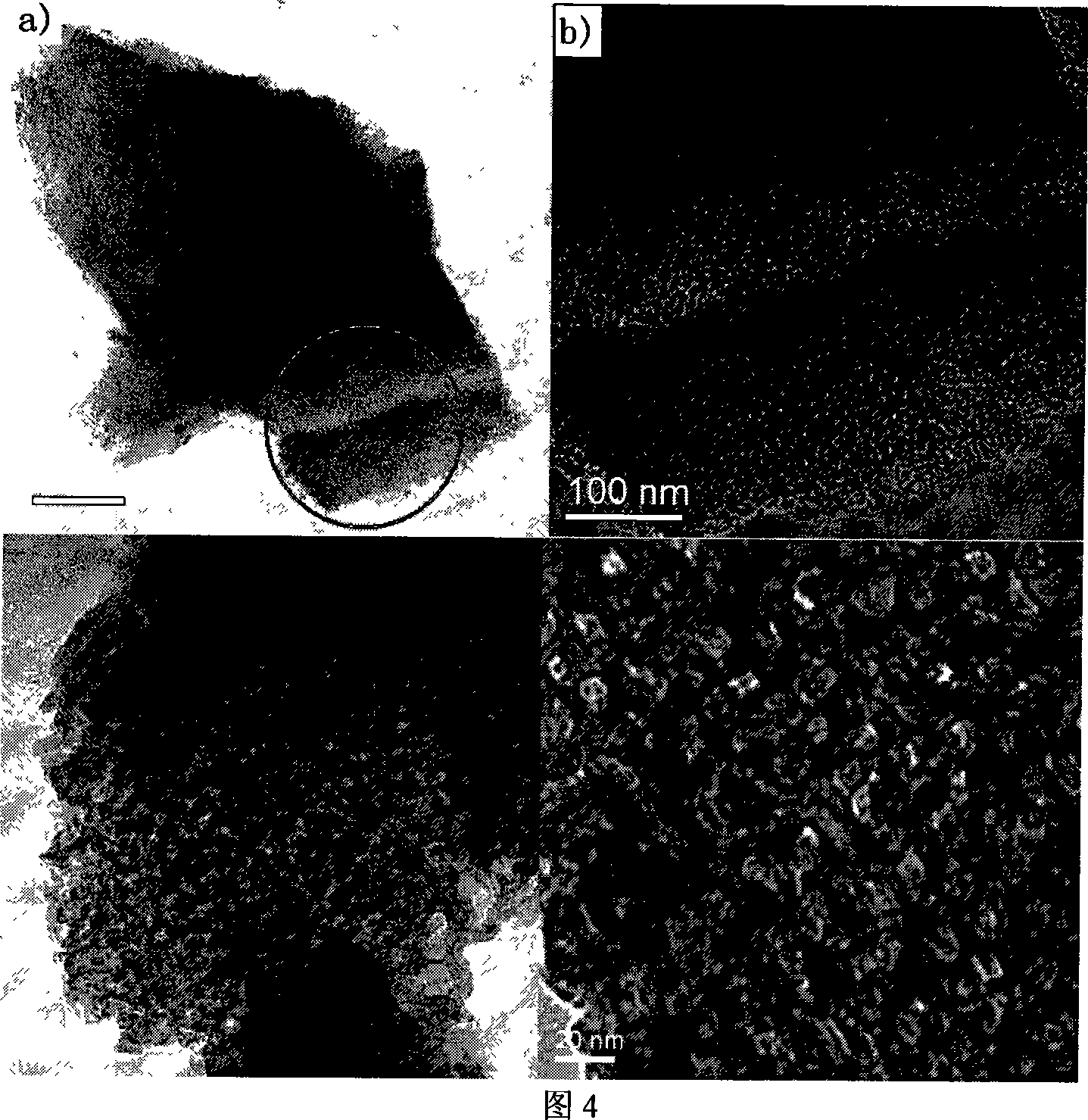

[0052] Dissolve 0.004molSrCO3 in 20ml glacial acetic acid and add 5ml H 2 O, accelerate the dissolution in ultrasound to obtain a clear liquid, add 0.65g of P123 to the mixture, stir for 20min, slowly add 0.004mol of titanium isopropoxide to the mixture, stir for 3 hours, and transfer the resulting clear solution to the incubation Place the dish in a 40°C oven for 3 days, and take out the scraped dry gel. The obtained xerogel was calcined in the air at 500°C for 5 hours to obtain the multi-element metal oxide semiconductor mesoporous SrTiO 3 powder.

Embodiment 2

[0054] 2.95g SrCO 3 Add to 60ml glacial acetic acid, add 10ml H 2 O. Heat and stir overnight to obtain a clear solution. 0.02 mol of tetrabutyl titanate was added to 16 g of ethanol and stirred for 5 hours to obtain a clear solution. The latter solution was added to the previously obtained solution and stirred vigorously for one hour. Then, 2 g of surfactant (P123) was added to the obtained solution and stirred for 2 hours to obtain a clear solution. The clear solution was poured into a petri dish, placed in an oven at 40°C, and aged for 60 hours, then the xerogel was scraped off, and the resulting xerogel was calcined in the air at 550°C for 5 hours. Mesoporous SrTiO 3 powder.

Embodiment 3

[0056] Add 8 g of citric acid to 10 g of water, stir to obtain a clear solution, and add 5 ml of ethanol. Then 2.95gSrCO 3 Add to the above solution and stir for 5 hours until it is clear. Add 0.02mol of titanium isopropoxide and stir for 1 hour until it is completely clear. Add 2 g of surfactant (P123) to the resulting solution and stir for 2 hours to obtain a clear solution. The clear solution was poured into a petri dish, placed in an oven at 40°C, and aged for 60 hours, then the xerogel was scraped off, and the resulting xerogel was calcined in the air at 550°C for 5 hours. Mesoporous SrTiO 3 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com