Foaming polystyrene plate surface defeathering and flaying machine thereof

A technology of expanded polystyrene and peeling machine, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., which can solve the problems of increasing construction links, construction materials, and construction costs of insulation systems, and achieve environmental protection Clean and hygienic, compact structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

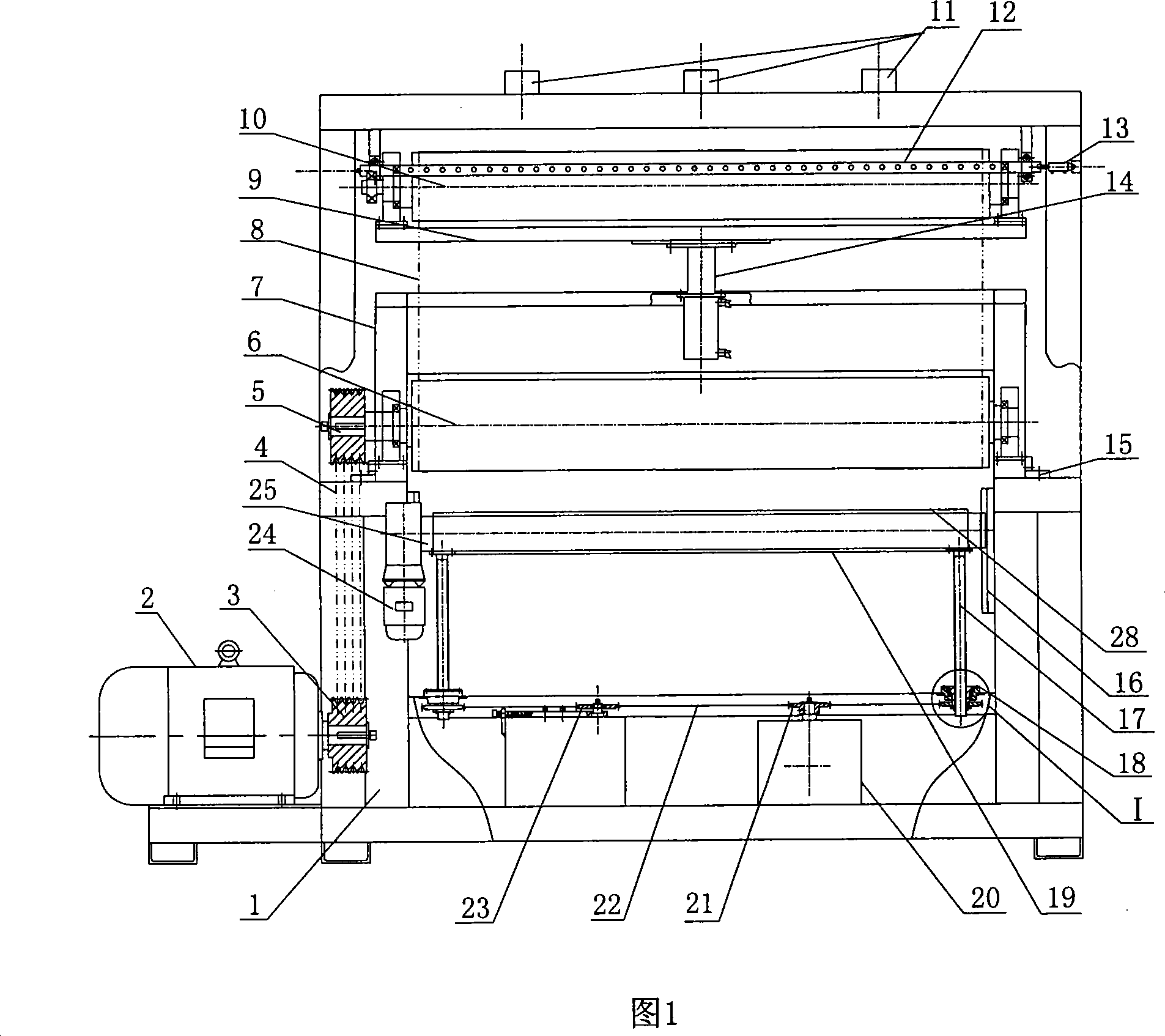

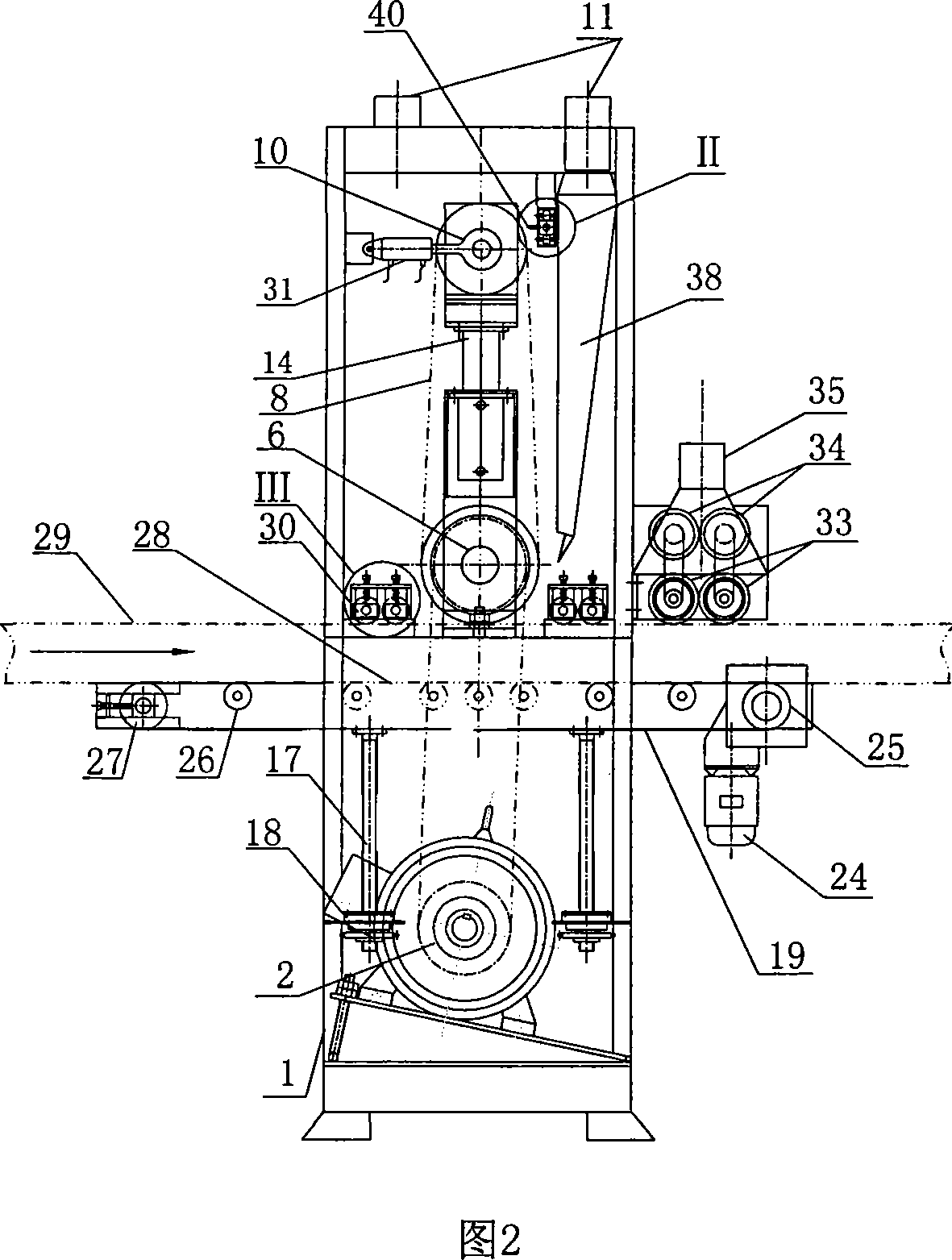

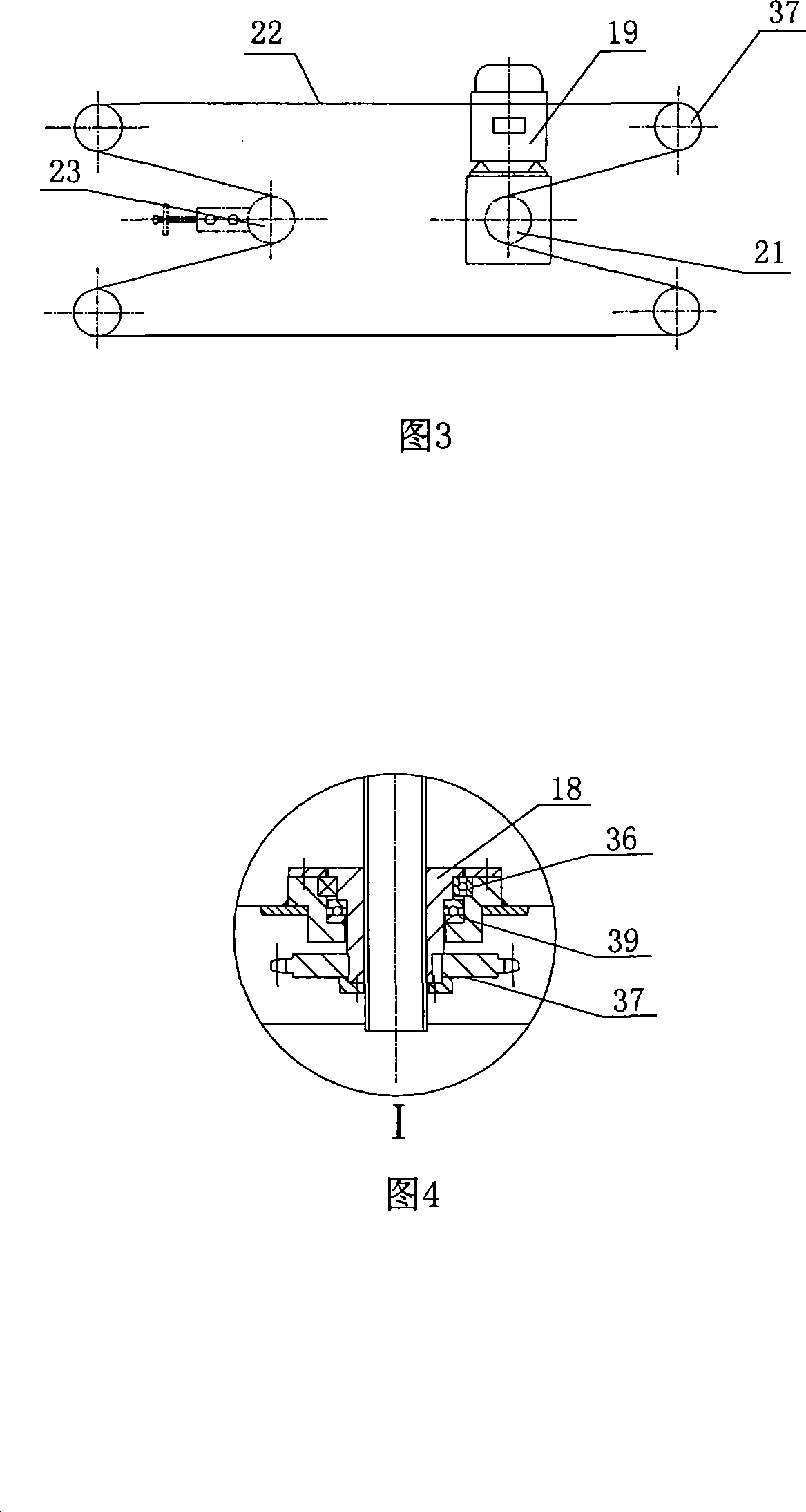

[0018] Referring to the accompanying drawings 1-6, the surface roughening and peeling machine for expanded polystyrene sheets is composed of a sheet roughening and peeling mechanism, a sheet conveying mechanism, a dust removal device, and a frame 1, and the sheet conveying mechanism is installed at the lower part of the frame 1 , The plate roughening and peeling mechanism is installed on the upper frame 1, and the dust removal device is fixed on the frame 1 in different regions. The roughening and peeling machine on the surface of the foamed polystyrene sheet can be driven by the motor to drive the transmission nut 18 and the driving screw 17 according to the thickness of the peeled sheet to rise and fall to adjust the use height of the rubber belt traction workbench 19.

[0019] The plate roughening and peeling mechanism mainly includes emery cloth belt 8, emery cloth belt peeling driving roller 6, emery cloth belt peeling driven roller 10, emery cloth belt peeling roller driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com