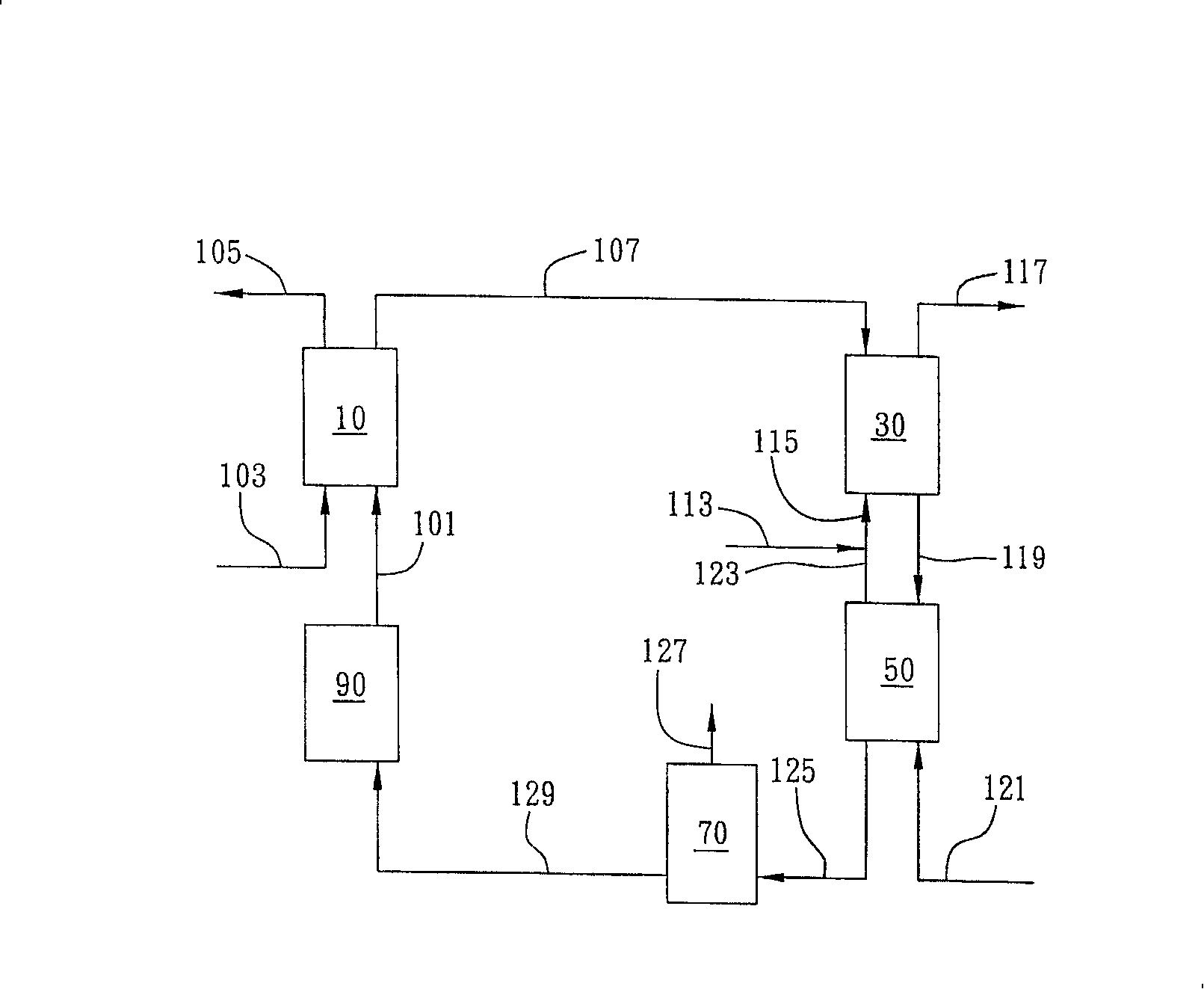

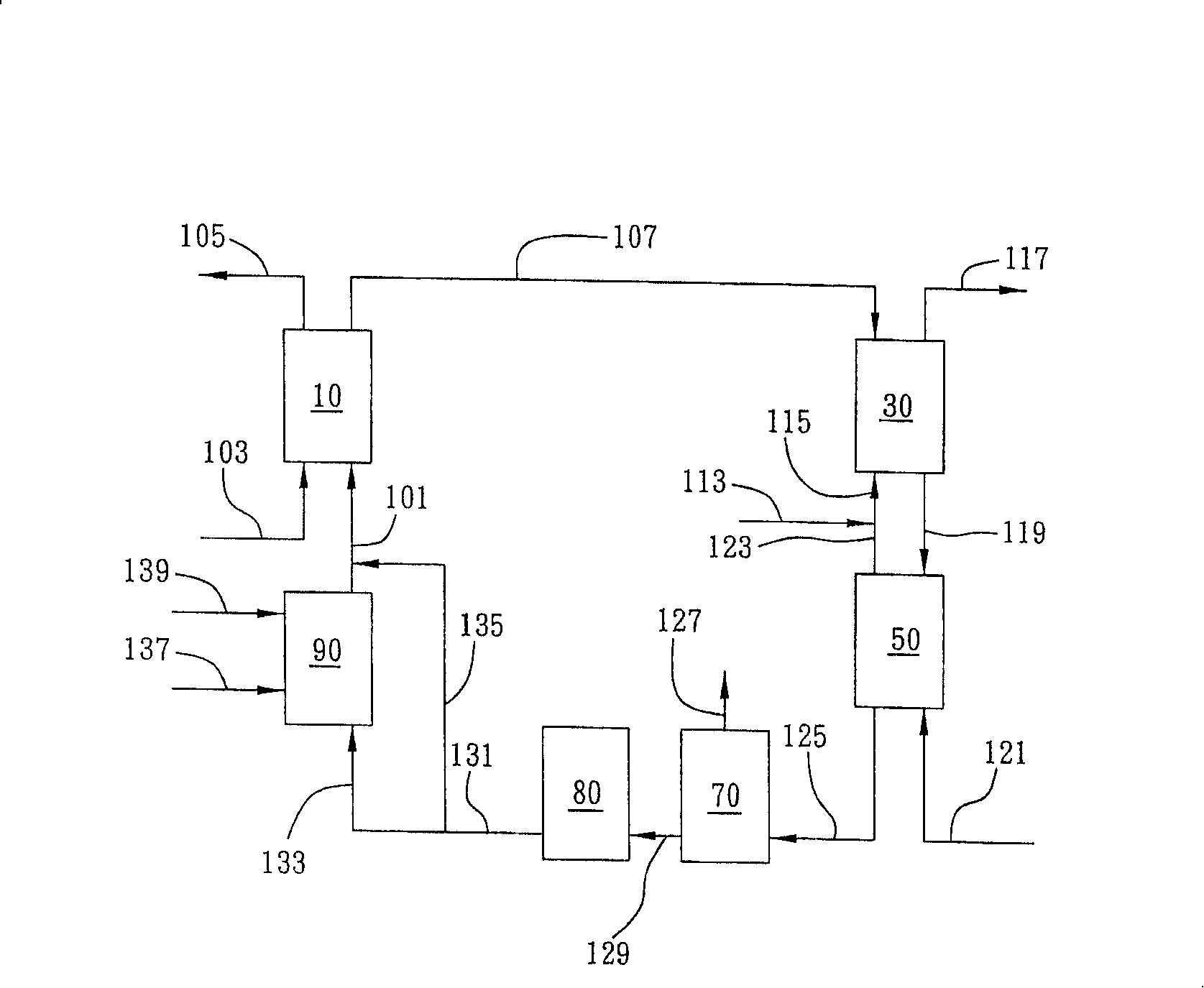

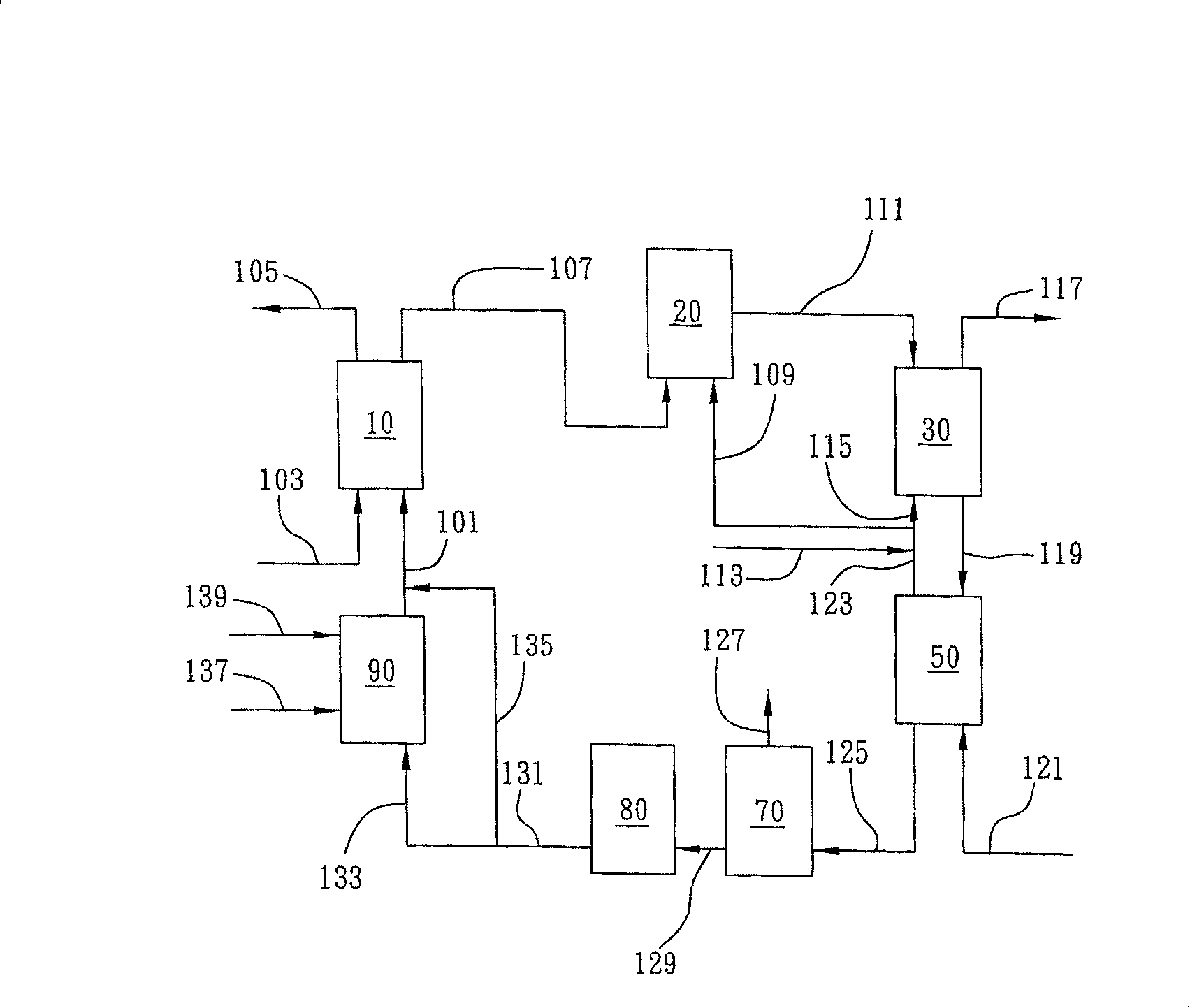

Hydroxylamine-oximation circulatoing system

A circulatory system and hydroxylamine technology, applied in the preparation of hydroxylamine and oxime, organic chemistry, etc., can solve problems such as unfavorable overall reaction, difficult removal of organic pollutants, corrosion of contact materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The phosphate inorganic treatment solution is continuously fed to the hydroxylamine reactor per unit time, and the inorganic treatment solution contains 2.88 mol / kg of hydrogen ions, 2.68 mol / kg of phosphate, and 0.20 mol / kg of free nitric acid. Hydroxylamine phosphate was synthesized at a temperature of 53° C. and a hydrogen partial pressure of 55%, using 10% palladium / activated carbon catalyst (manufactured by Japan Degussa Company) for catalysis. In the phosphate inorganic treatment liquid at the outlet of the hydroxylamine reactor, the concentration of the synthesized hydroxylamine phosphate is 1.14 mol / kg.

[0048] The hydroxylamine phosphate inorganic treatment solution and the toluene solution containing cyclohexanone are continuously fed into the oximation tower from the top and bottom of the oximation tower for oximation reaction (the operating temperature of the oximation tower is 51° C.). The molar ratio is 0.90. In the organic phase overflowing from the top...

Embodiment 2

[0053] The phosphate inorganic treatment solution is continuously fed to the hydroxylamine reactor per unit time, and the inorganic treatment solution contains 3.45 mol / kg of hydrogen ions, 3.05 mol / kg of phosphate, and 0.58 mol / kg of free nitric acid. Hydroxylamine phosphate was synthesized at a temperature of 53° C. and a hydrogen partial pressure of 55%, using 10% palladium / activated carbon catalyst (manufactured by Japan Degussa Company) for catalysis. In the phosphate inorganic treatment liquid at the outlet of the hydroxylamine reactor, the concentration of the synthesized hydroxylamine phosphate is 1.41 mol / kg.

[0054] The inorganic treatment solution of hydroxylamine phosphate is firstly fed into the premixing reactor in the same direction as part of the toluene solution of cyclohexanone, and premixed at a temperature of 37° C. and a pressure of one atmosphere. In the mixed reaction liquid discharged from the premixing reactor, the concentration ratio of hydroxylamine...

Embodiment 3

[0060] The phosphate inorganic treatment solution is continuously fed to the hydroxylamine reactor per unit time, and the inorganic treatment solution contains 4.00 mol / kg of hydrogen ions, 3.27 mol / kg of phosphate, and 0.72 mol / kg of free nitric acid. Hydroxylamine phosphate was synthesized at a temperature of 53° C. and a hydrogen partial pressure of 55%, using 10% palladium / activated carbon catalyst (manufactured by Japan Degussa Company) for catalysis. In the phosphate inorganic treatment liquid at the outlet of the hydroxylamine reactor, the concentration of the synthesized hydroxylamine phosphate is 1.64 mol / kg.

[0061] The inorganic treatment solution of hydroxylamine phosphate is firstly fed into the premixing reactor in the same direction as part of the toluene solution of cyclohexanone, and premixed at a temperature of 37° C. and a pressure of one atmosphere. In the mixed reaction liquid discharged from the premixed reactor, the concentration ratio of hydroxylamine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com