Cleaning method of single polycrystalline battery piece recovery piece

A technology for battery slices and cleaning boxes, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of reducing the electrical properties of materials, reducing material quality, and polycrystalline impurities, achieving good rinsing effect and increasing income. rate, the effect of reducing the loss ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

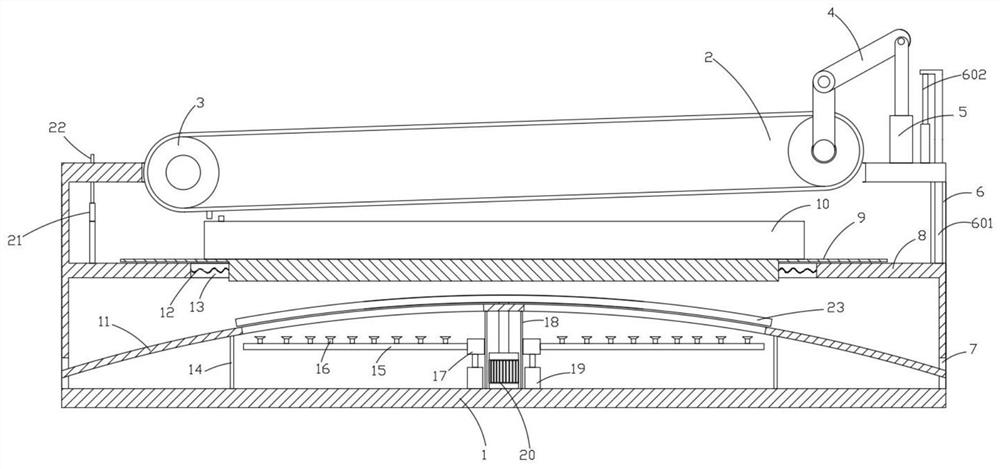

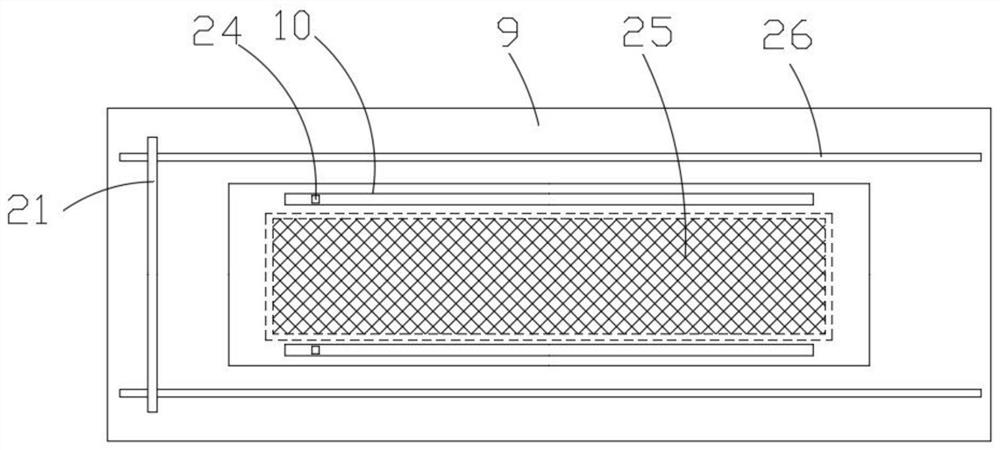

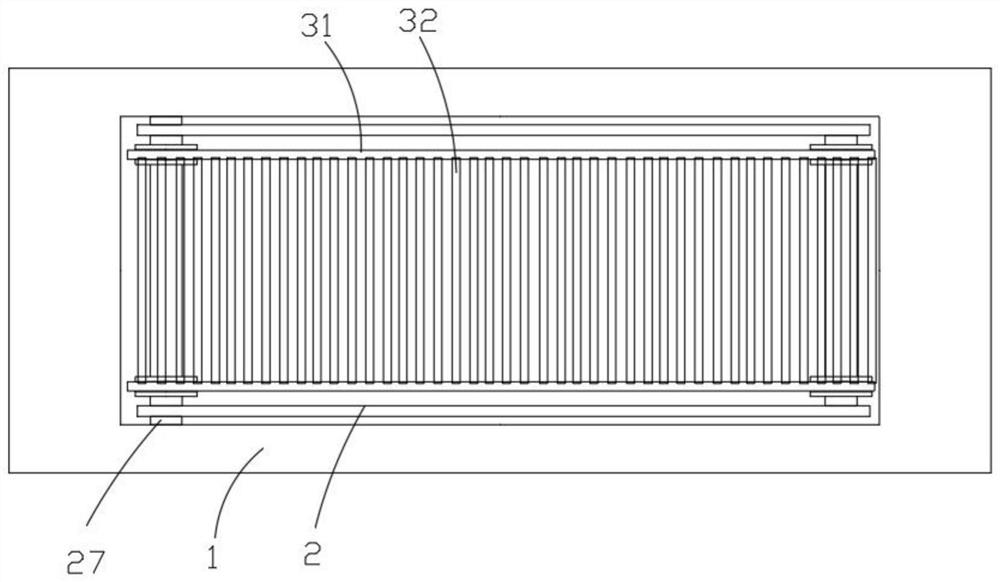

Method used

Image

Examples

Embodiment 1

[0032] A method for cleaning single-polycrystalline cells recovered sheets, comprising the following steps:

[0033] 1. Break the recycled single-polycrystalline battery sheet into an area of 8cm 2 left and right small fragments;

[0034] 2. Then put the small pieces into the hydrofluoric acid solution, stir well and soak for 15 minutes;

[0035] 3. After the soaking is completed, pick up the small pieces and put them into the mixed solution of nitric acid and hydrofluoric acid for reaction, and stir for 5 minutes. After the reaction is fully carried out, take out the small pieces of the battery and neutralize the battery with sodium hydroxide Then use the cleaning equipment to rinse the small pieces of the battery several times to remove the residue after the reaction, and measure the pH value of the rinsed liquid at the same time. The measured pH value of the liquid after rinsing is about 7 hours;

[0036] 4. After rinsing, use ultrasonic waves to clean the four sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com