Regenerated cellulose spinning solution and its solvent and preparation method

A technology of regenerated cellulose and spinning dope, applied in the field of chemical fiber spinning, can solve the problems of easy decomposition of NMMO, unfavorable recovery and reuse of NMMO, high solution melting point and high viscosity, so as to shorten the dissolution time, increase production and economical Benefit, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

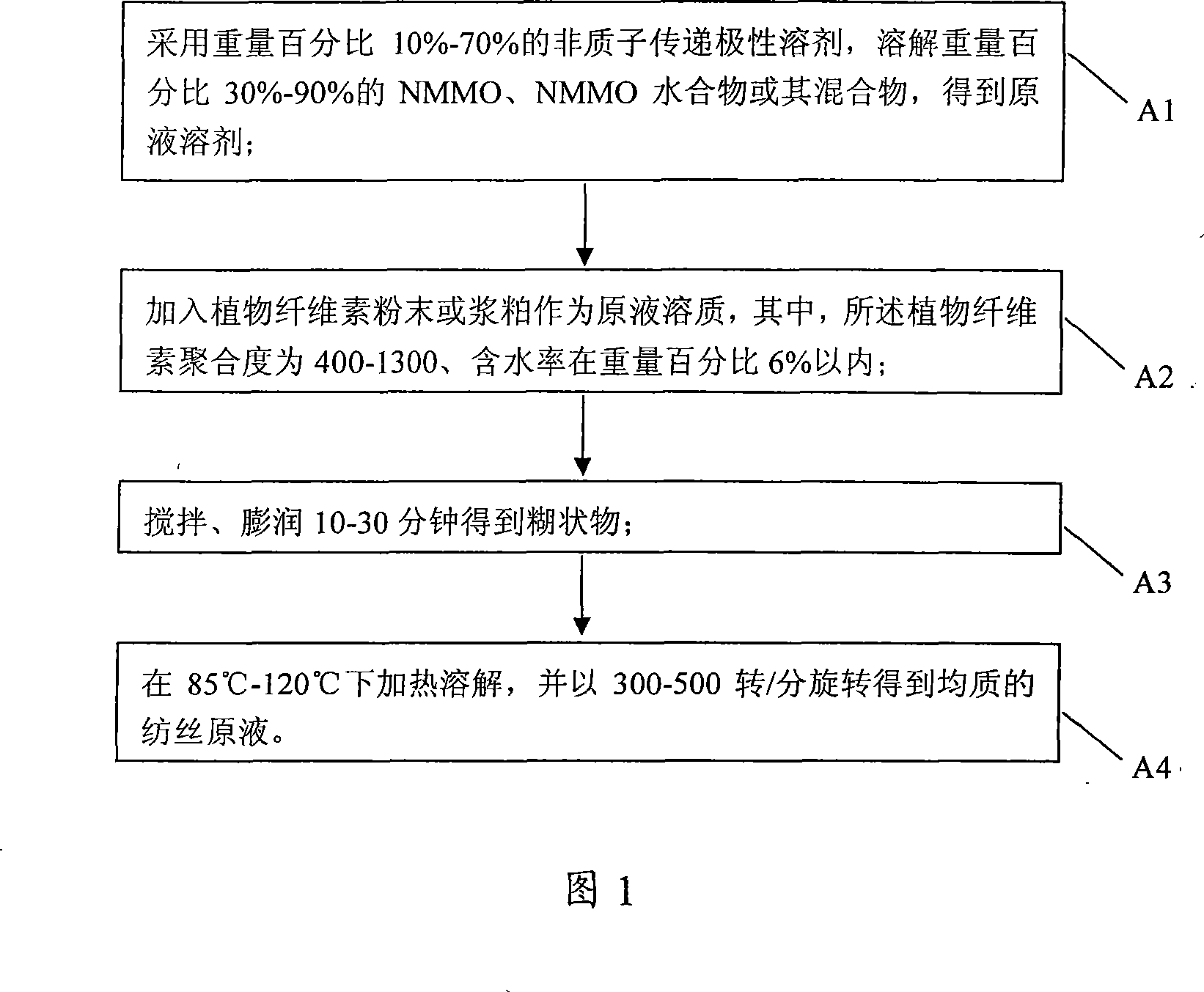

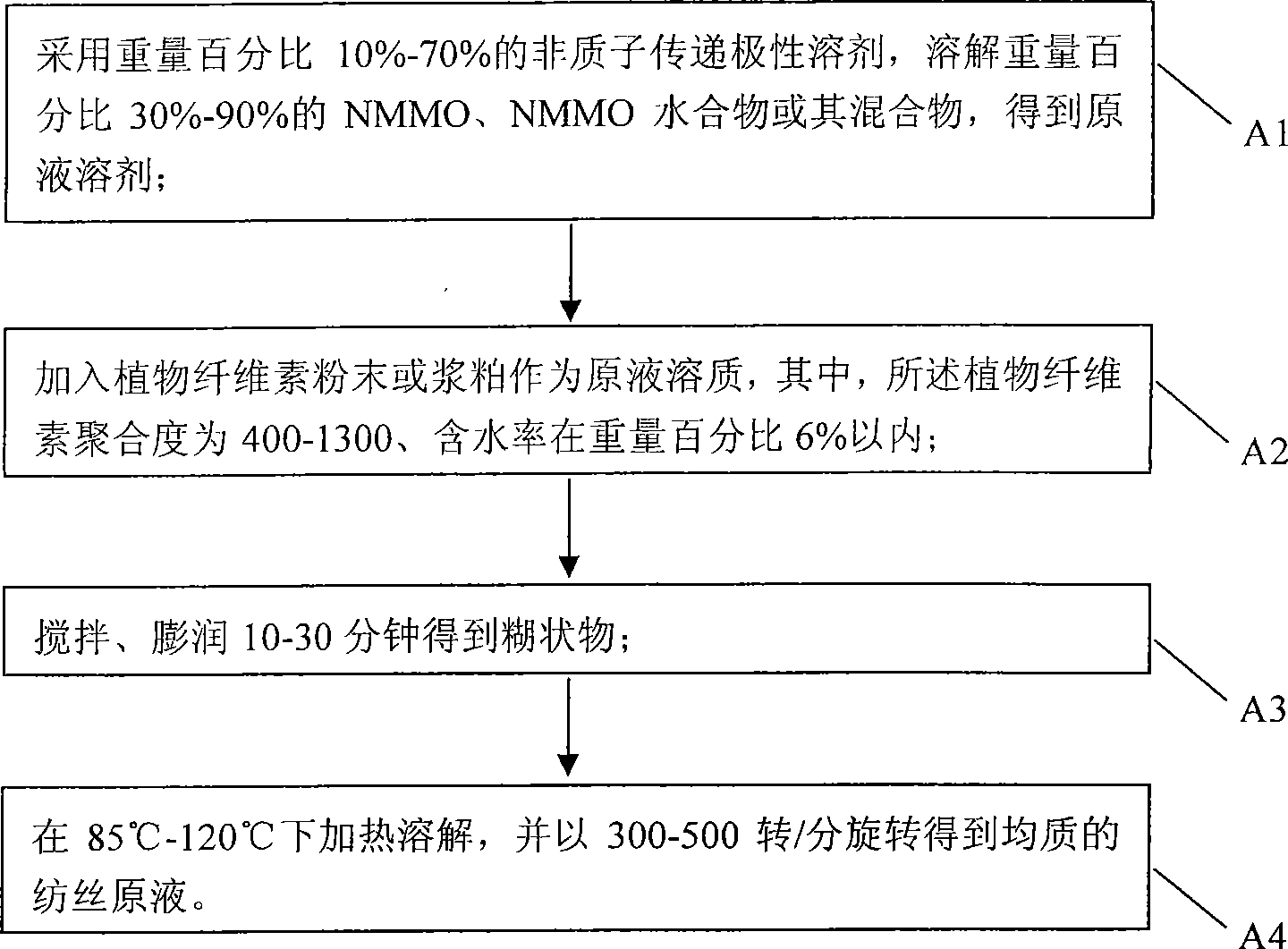

Method used

Image

Examples

Embodiment Construction

For example, dissolve NMMO, NMMO monohydrate or NMMO dihydrate in dimethyl sulfoxide at room temperature, or at 60-70°C, or add NMMO trihydrate and / or NMMO tetrahydrate as spinning The solvent of the stock solution, the water content of the solvent is within 15% by weight. Alternatively, the water content is within 13%, 13.5%, 14.5% or 14%, as long as the water content is within 15%; the weight percentage of dimethyl sulfoxide and NMMO or its hydrate is 10-70:90-30 ; for example, 20% dimethyl sulfoxide and 80% NMMO, or 40% dimethyl sulfoxide and 40% NMMO hydrate, and 20% NMMO dihydrate, or 60% dimethyl sulfoxide and 40% NMMO monohydrate, or 50% dimethyl sulfoxide and 20% NMMO dihydrate and 30% NMMO monohydrate, or 65% dimethyl sulfoxide and 20% NMMO monohydrate, 10% NMMO dihydrate, 5% NMMO trihydrate, etc.; and add 0.05%-0.1% by weight heat stabilizer to the mixed solvent, such as 0.06% propyl gallate , that is, propyl gallate (PG), is used to reduce thermal degradation of NM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com