Thin-walled body strengthen porcelain and production technique thereof

A technology for strengthening porcelain and alumina, which is applied in the field of thin-bore reinforced porcelain and its production technology, which can solve the problems of difficult molding, low glaze hardness, and many pores on the glaze surface, and achieve reduced resource consumption, high mechanical strength, and not easy deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A thin-bodied reinforced porcelain, the body of which includes the following components (by weight): 27.5% kaolin, 35.0% weathered potassium feldspar, 17.5% quartz, 9.0% α-alumina single crystal, 2.5% zirconia single crystal , Bentonite 7.0% and Talc 1.5%.

[0027] Described kaolin contains (by weight percentage): Al 2 O 3 36% and SiO 2 49%.

[0028] Described weathered potassium feldspar contains (by weight percentage): K 2 O5.5%, Al 2 O 3 19.5%, SiO 2 69%, Na 2 O0.008%, CaO0.008%, and MgO0.016%.

[0029] Described bentonite contains (by weight percentage): SiO 2 71.5%, Al 2 O 3 15%, MgOl.5%, K 2 O1%, Na 2 O0.018% and CaO0.4%.

[0030] SiO in the quartz 2 The content is 99.5% (by weight).

[0031] The content of the α-alumina single crystal corundum is 99.5% (percentage by weight).

[0032] The various minerals are selected to contain Fe 2 O 3 2 <0.02% premium product (percentage by weight).

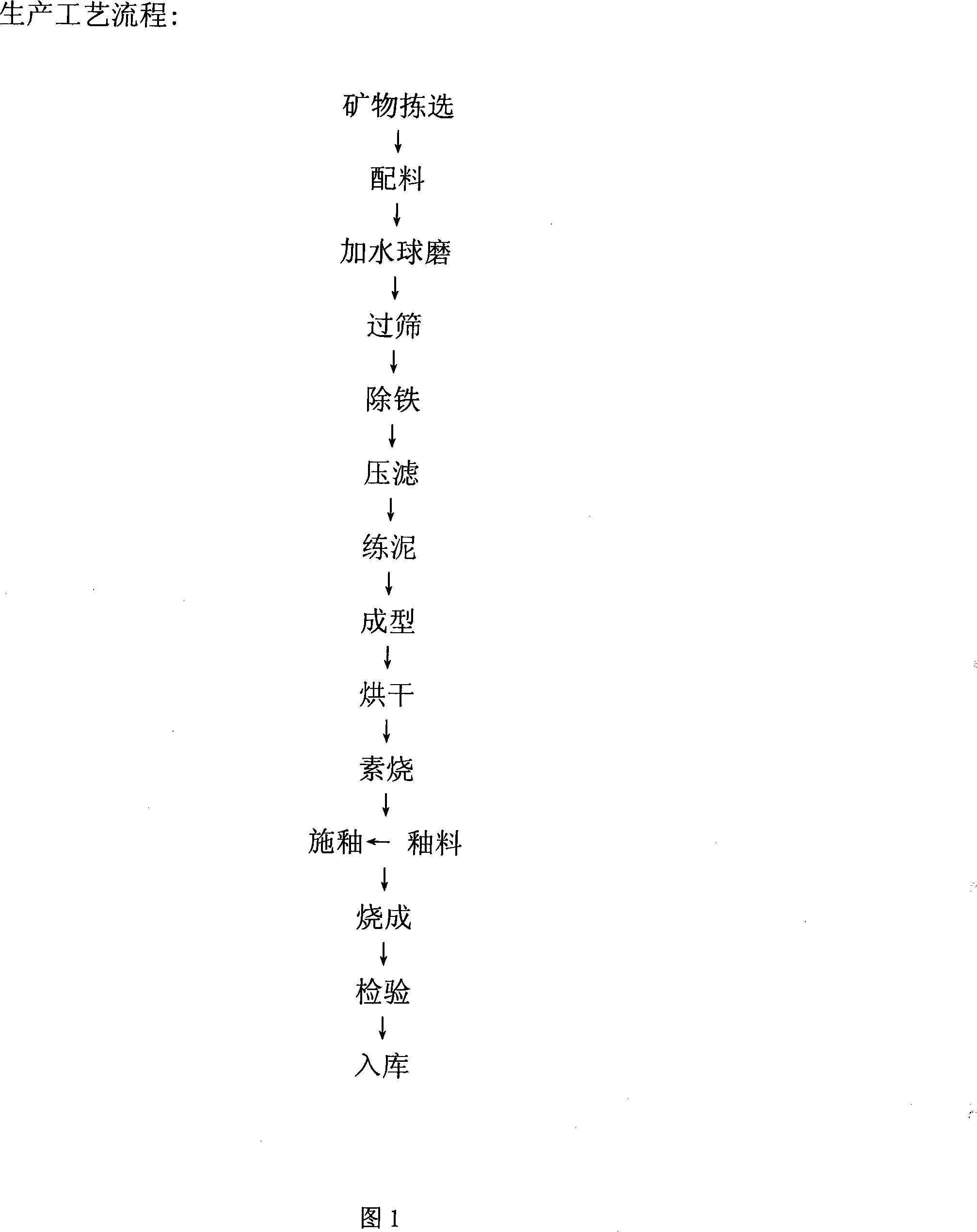

[0033] The production process of the thin body strengthe...

Embodiment 2

[0035] A kind of thin-bodied reinforced porcelain, whose green body includes the following components (by weight): 25% of kaolin, 38% of weathered potassium feldspar, 18% of quartz, 10% of α-alumina single crystal, 2% of zirconia single crystal , Bentonite 6% and Talc 1%.

[0036] Described kaolin contains (by weight percentage): Al 2 O 3 37% and SiO 2 48%. Weathered potassium feldspar contains (by weight percentage): K 2 O6%, Al 2 O 3 19%, SiO 2 70%, Na 2 O0.008%, CaO0.008%, and MgO0.018%. Bentonite contains (by weight percent): SiO 2 72%, Al 2 O 3 16%, MgO 2 %, K 2 Ol%, Na 2 O0.015% and CaO0.4%. SiO in quartz 2 The content is 99.2% (by weight). The content of α-alumina single crystal corundum is 99.2% (percentage by weight). Various minerals are selected to contain Fe 2 O 3 2 <0.02% premium product.

[0037] The production process of thin body reinforced porcelain includes the following steps: mineral selection, batching, ball milling with water, sieving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com