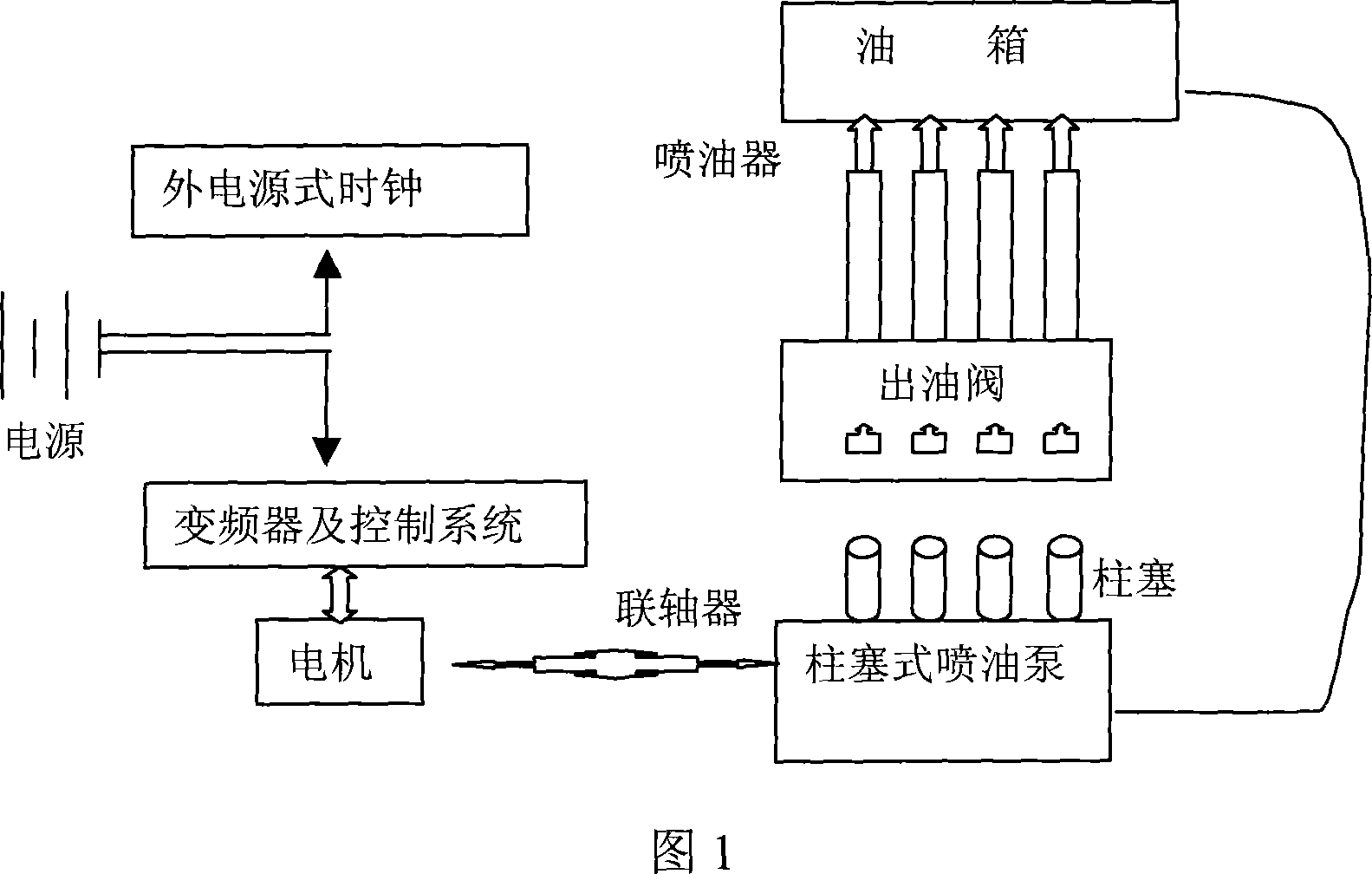

Method for assessing diesel actual abrasion resistance performance and bed test device

A bench test, diesel technology, applied in the direction of measuring device, engine test, machine/structural component test, etc., can solve problems such as large error and cumbersome procedures, and achieve the effect of low cost, good versatility and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The -10# diesel oil from Shengli Oil Refinery was used, its sulfur content was 0.169%, and the lubricity value of diesel oil evaluated by HFRR was 521 μm. The above-mentioned test device and method conditions were used to conduct a 750-hour bench test, that is, the oil pump was driven by the motor at 570r / min, the governor was relatively fixed, the initial circulation oil was 701, and the ambient temperature was kept at 25±5°C during the test. See Table 1 for the fuel injection atomization of the oil pump before and after the test, Table 2 for the shape change of the needle valve couple, Table 3 for the mass loss of the couple, and Table 4 for the performance change of the couple.

[0024] Table 1 Oil pump spray atomization after bench test

[0025] Test items

[0026] Table 2 Morphology analysis of needle valve couple before and after bench test

[0027] serial number

[0028] Table 3 The mass and loss of each pair before and after the bench test...

Embodiment 2

[0035] (1) Test oil: Hydrogenated diesel oil from Shengli Oil Refinery, sulfur content 0.004%, HFRR corrected wear scar value 560μm

[0036] (2) After the test, the drop value of the sealing performance of the diameter of the plunger coupling (the drop value of the pressure-holding seconds) is 3.675 seconds, and its actual anti-wear performance is poor, which cannot meet the actual anti-wear requirements of the high-pressure injection system.

Embodiment 3

[0038] (1) Test oil: diesel oil from Maoming Oil Refinery, sulfur content 0.061%, HFRR corrected wear scar value 422μm

[0039] (2) After the test, the drop value of the sealing performance of the diameter of the plunger coupling (the drop value of the pressure holding seconds) is 0.55 seconds, and its actual anti-wear performance is good, which meets the actual anti-wear requirements of the high-pressure injection system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com