Method of preparing water treatment material anionic dye sorbent

An anionic dye and adsorbent technology, which is applied in the direction of adsorption of water/sewage treatment, chemical instruments and methods, and other chemical processes, and can solve problems such as poor adsorption effect, poor adsorption performance, and increased interlayer spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

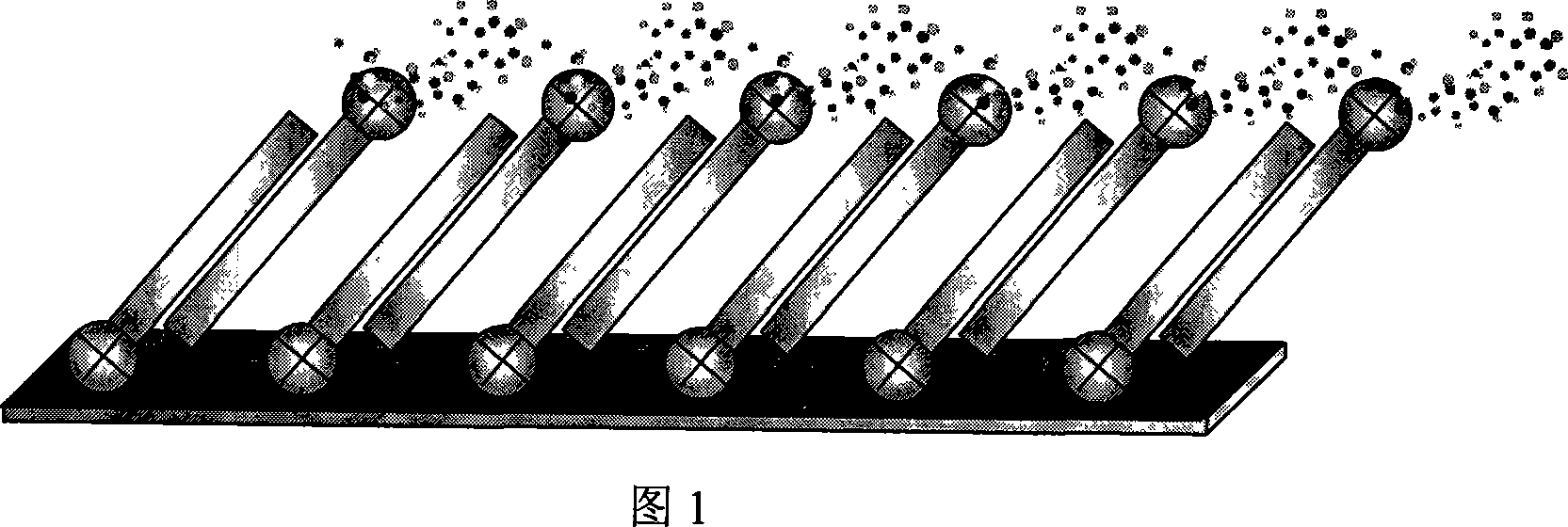

Image

Examples

Embodiment 1

[0012] Add the pulverized 80-mesh calcium-based bentonite into the solution in which the cationic surfactant cetyltrimethylammonium bromide is dissolved, the amount of the surfactant is 100% of the cation exchange capacity of bentonite, and stir for 2 hours; then add ten Tetraalkyltrimethylammonium bromide, the amount of which is also 100% of the cation exchange capacity of bentonite, was stirred for 2 hours; the precipitate was washed 3 times with distilled water, baked at 110°C for 3 hours, ground, and passed through a 60-mesh sieve.

[0013] The obtained product was used for wastewater treatment containing Dye Orange II, and the results showed that the removal rate of Dye Orange II was 98% when the concentration of wastewater was 80 mg / L and the weight ratio of adsorbent to wastewater was 1:1000.

Embodiment 2

[0015] Add the pulverized 150-mesh sodium bentonite into the solution in which the cationic surfactant octadecyltrimethylammonium bromide is dissolved, the amount of the surfactant is 100% of the cation exchange capacity of bentonite, and stir for 3 hours; then add ten Dialkyltrimethylammonium chloride and octaalkyltrimethylammonium chloride, the total amount of which is 100% bentonite cation exchange capacity, stirred for 3 hours; washed the precipitate with distilled water for 5 times, baked at 120°C for 4 hours, and ground , through a 100-mesh sieve.

[0016] The obtained product was used for the treatment of wastewater containing dye acid red, and the results showed that the removal rate of dye acid red was 95% when the concentration of wastewater was 80 mg / L and the weight ratio of adsorbent to wastewater was 1:500.

Embodiment 3

[0018] Add the pulverized 200-mesh calcium-based bentonite into the solution in which the cationic surfactant octadecyltrimethylammonium chloride is dissolved, the amount of the surfactant is 100% of the cation exchange capacity of bentonite, and stir for 2.5 hours; then add Dodecylpyridinium chloride and cetyltrimethylammonium bromide, the total amount of which is 100% bentonite cation exchange capacity, was stirred for 3 hours; the precipitate was washed with distilled water for 4 times, baked at 115°C for 3.5 hours, and ground. Pass 80 mesh sieves.

[0019] The obtained product was used for wastewater treatment containing Dye Orange II, and the results showed that the removal rate of Dye Orange II was 97% when the wastewater concentration was 50 mg / L and the weight ratio of adsorbent to wastewater was 1:500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com