Wide band high pressure intelligent resistance type current sensor

A current sensor and resistive technology, which is applied in the field of broadband high-voltage intelligent resistive current sensor, can solve problems such as interference, affecting test accuracy, and long signal transmission lines, achieving low-temperature drift, strong anti-interference ability, and no secondary open-circuit high voltage dangerous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

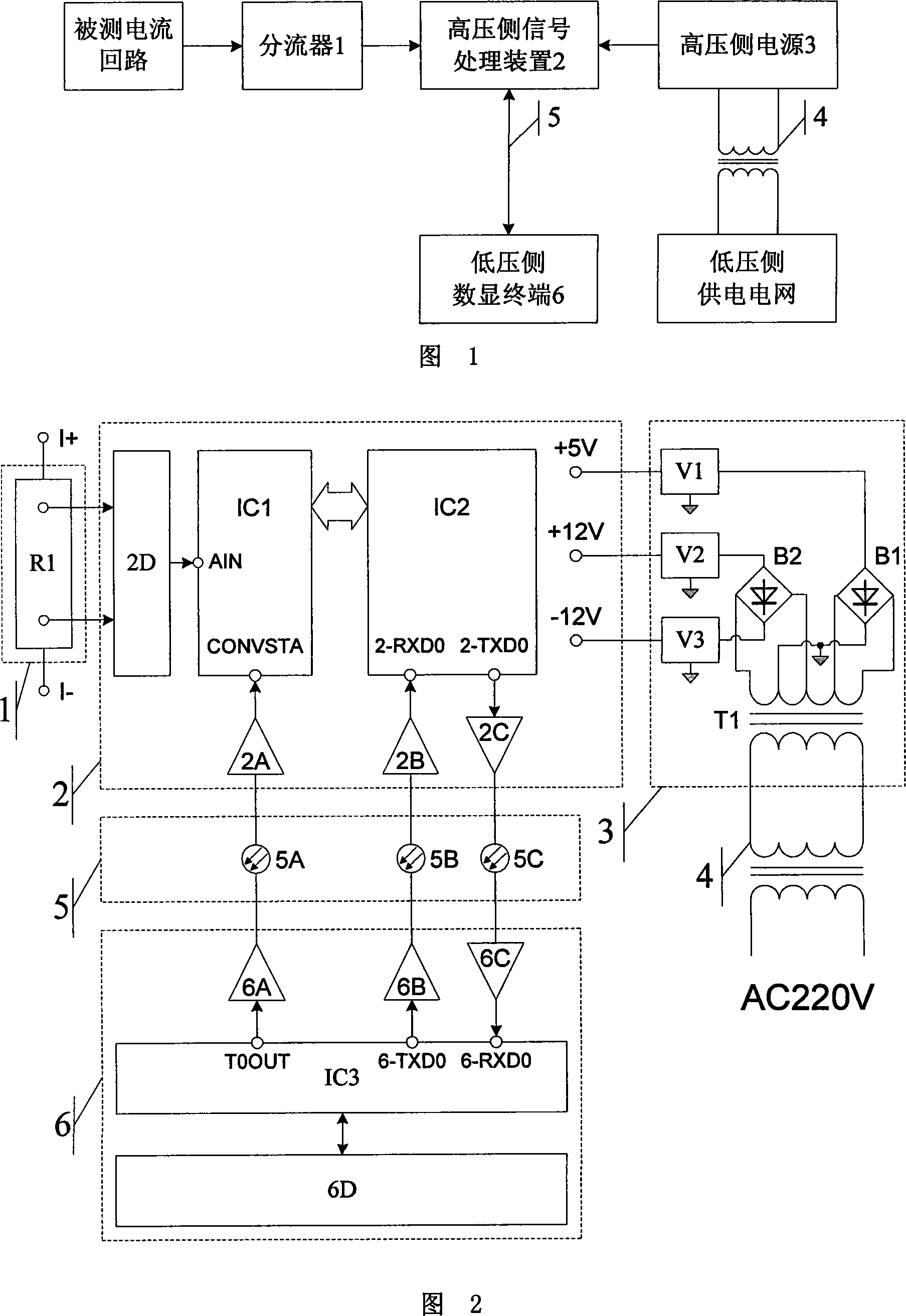

[0023] Embodiment 1: With reference to Fig. 1 and Fig. 2:

[0024] In this embodiment, the low-voltage side power supply grid adopts AC220V mains power.

[0025] As a current sensing device, the shunt (1) is connected to both ends of the measured current loop I+ and I-, and converts the measured current into a millivolt-level analog voltage signal and connects it to the high-voltage side signal processing device (2), and the high-voltage side signal processing The device (2) converts the analog voltage signal output by the shunt (1) into a digital signal and uploads it to the low-voltage side digital display terminal (6) through the optical fiber group (5) after calculation and processing, and the high-voltage side power supply (3) is the high-voltage side signal The processing device (2) provides working power, and the primary side and the secondary side of the high-voltage isolation transformer (4) are respectively connected to the AC220V mains power supply and the high-volt...

Embodiment 2

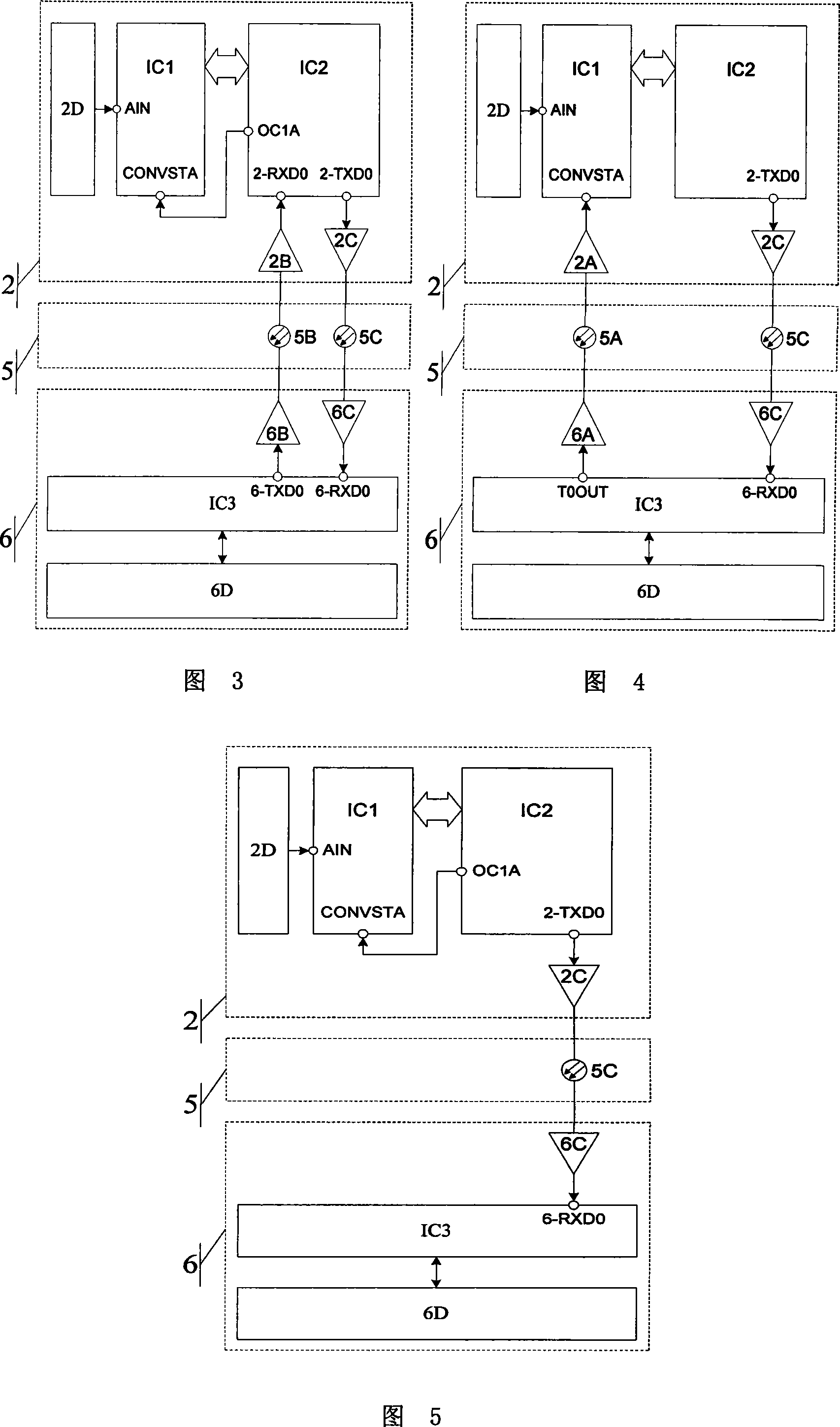

[0036] With reference to accompanying drawing 3: (omit among the figure 2 identical shunt 1, high-voltage side power supply 3, high-voltage isolation transformer 4), the difference of this embodiment and embodiment 1 is, in the present embodiment, broadband high-voltage smart resistance The current sensor does not care about the sampling time of the measured signal, that is, it does not need to sample synchronously with other signals or perform phase comparison, so the high-voltage side signal processing device (2) saves the sampling clock receiver 2A, and the communication optical fiber group (5) saves The communication optical fiber 5A, the low-voltage side digital display terminal (6) saves the sampling clock transmitter 6A, and simultaneously connects the A / D conversion start signal CONVSTA of the A / D converter IC1 directly to the clock output pin OC1A of the microprocessor IC2, The sampling clock signal is provided by IC2.

Embodiment 3

[0038] With reference to accompanying drawing 4: (omit among the figure 2 same shunt 1, high-voltage side power supply 3, high-voltage isolation transformer 4), the difference between this embodiment and embodiment 1 is, in the present embodiment, broadband high-voltage smart resistance The current sensor does not need to set various instructions, so the high-voltage side signal processing device (2) saves the serial data receiver 2B, the communication fiber group (5) saves the communication fiber 5B, and the low-voltage side digital display terminal (6) saves the serial data row data transmitter 6B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com