Anti-oxidation protection of pieces made from a composite material containing carbon

A technology of composite materials and parts, which is applied in the field of anti-oxidation protection of parts made of carbon-containing composite materials, and can solve problems such as complete problems, environmental problems, and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

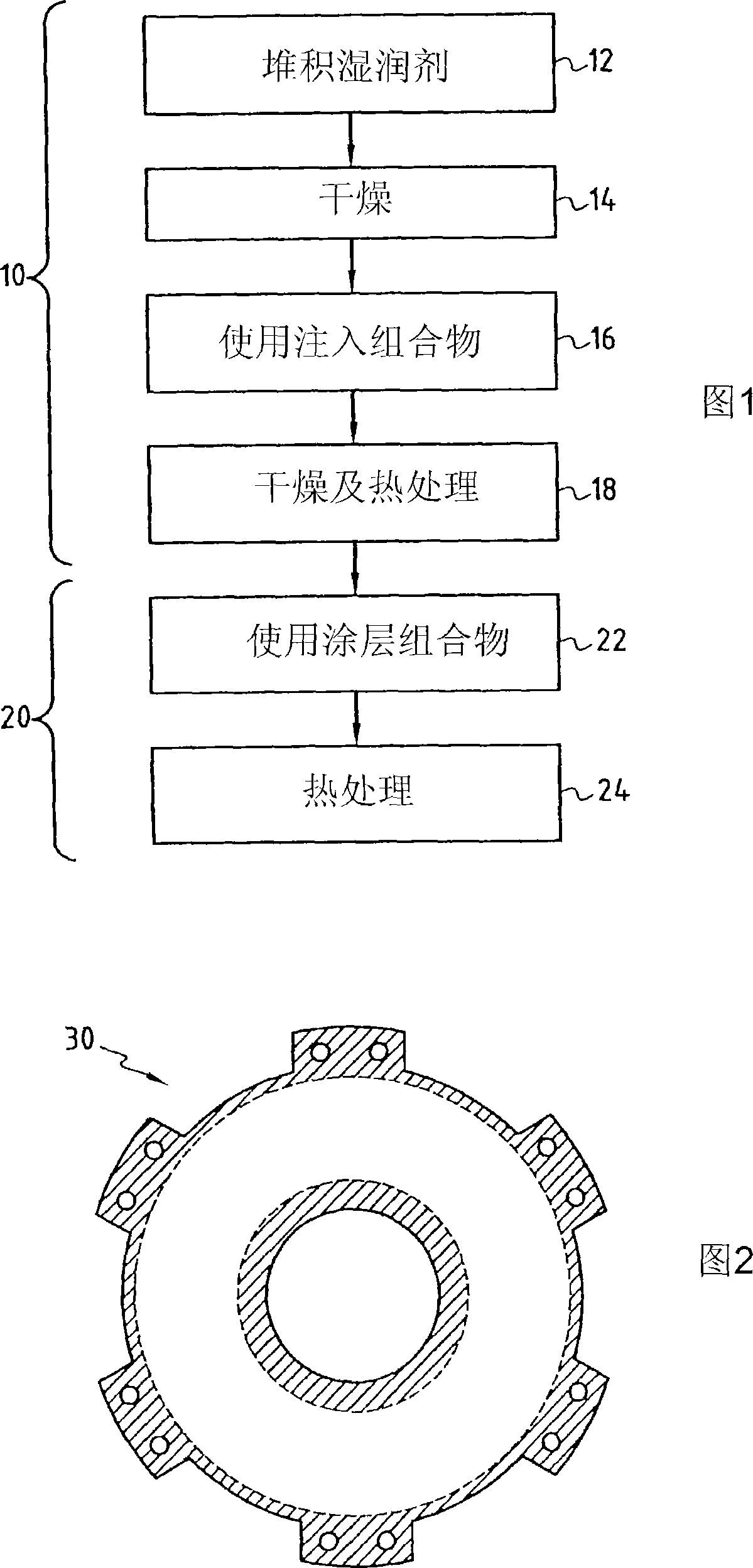

Method used

Image

Examples

Embodiment 1

[0075] Samples of C / C composites were prepared by:

[0076] Overlap three carbon fiber unidirectional thin plates with an angle of ±60° between them, and combine the thin plates with each other through light needling to form a fiber ply;

[0077] superimposing the fibreboard layers formed and bonding the plies to each other by needling as they are superimposed to obtain a thickness of a few centimeters;

[0078] cutting ring-shaped rough products from the fibrous sheet prepared as described above; and

[0079] The crude product was densified by a pyrolytic carbon matrix formed by chemical vapor infiltration to achieve a relative density of about 1.73.

[0080] The formed samples were injected with an aqueous solution containing 0.5% by weight of a wetting agent (surfactant) sold under the name "Marlophen 89" by the German supplier Hüls. For this purpose, the sample is immersed in said solution, which is located in a tank associated with an ultrasonic generator to facilitate ...

Embodiment 2

[0117] Sample D of the C / C composite was provided with the same outer protective layer as Sample C in Example 1, but the phosphate based inner protection was omitted. Table II below shows the results (relative weight loss) obtained for samples C and D under two oxidizing environments.

[0118] Table II

[0119]

[0120] The results obtained show that the combination of internal and external protection shows a great improvement compared to external protection alone.

Embodiment 3、4 and 5

[0122] Sample E was obtained by providing sample A of Example 1 with an external protection obtained by the following steps:

[0123] - Using 36.4 parts by weight of "FFB33K" colloidal silica at a concentration of 30%, 4.8 parts of water, 12.2 parts of "Pyrex" glass powder and 46.6 parts of TiB supplied by the supplier Alfa Aesar 2 The aqueous composition, the mass used is about 17mg / cm 2 ;and

[0124] - Heat treatment in air at 90°C for 2 hours.

[0125] Sample F was obtained similar to sample E but heat treated at 700° C. in nitrogen for 1 hour.

[0126] Sample F similar to sample E but obtained by heat treatment in air at 800° C. for 15 minutes was obtained.

[0127] Table III below shows the results (relative weight loss) obtained after carrying out the oxidation tests on samples E, F and G.

[0128] Table III

[0129] Oxidation conditions

[0130] Industrially, a short heat treatment in air at 800°C is preferred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com