Method for preparing Lactoferrins antibiotic peptide by enzyme method

A technology of lactoferrin and enzymatic preparation, applied in fermentation and other directions, can solve problems such as poor heat resistance, and achieve the effects of improving health level, high digestion and absorption rate, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

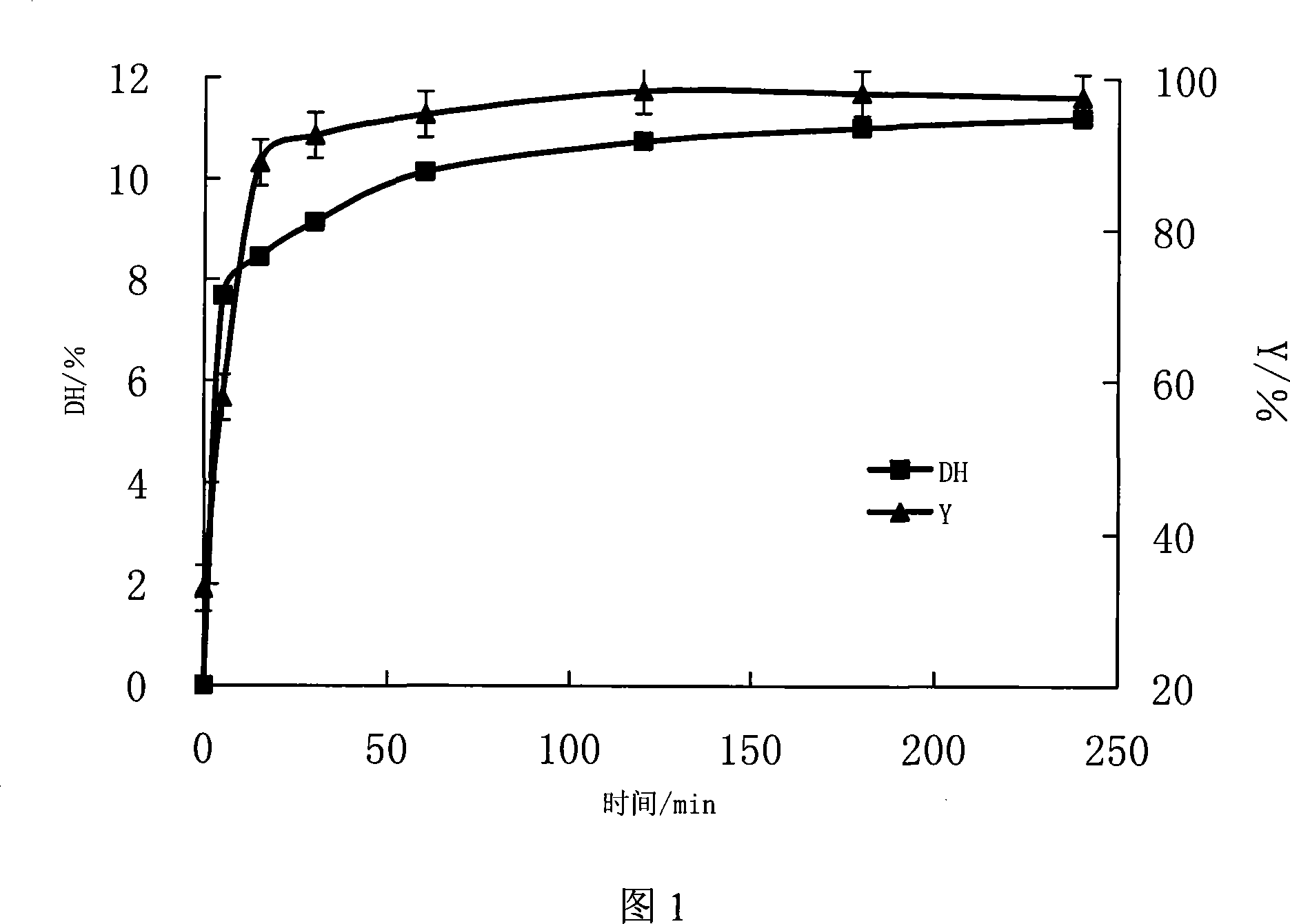

[0052] According to the above-mentioned process route in the specification, the lactoferrin solution with a mass concentration of 3% was added to a constant temperature reaction vessel with constant stirring. After reaching 45°C, the temperature was kept for 5 minutes, and the pH was adjusted to 2.5 with 1.0 mol / L HCl. Add porcine pepsin, the amount of enzyme added is 1% of the mass of the substrate lactoferrin. During the reaction, stirring was continued, and 1.0 mol / L HCl was added dropwise to maintain a constant pH. Enzymatic hydrolysis at 45°C for 2h, the reaction reached the end, the measured DH value was 13%, the stirring was stopped, and the temperature was quickly raised to 80°C and maintained for 15min to inactivate the enzyme. Add 1.0mol / L NaOH to adjust the pH to 7.0, and centrifuge at 15000×g for 30 min. The supernatant is freeze-dried, and the freeze-dried powder obtained is the lactoferrin antibacterial peptide with a bacteriostatic rate of 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com