Photo-etching machine projection objective wave aberration on-line detection method

A projection objective lens, wave aberration technology, applied in optomechanical equipment, microlithography exposure equipment, optics, etc., can solve problems such as slow detection speed, and achieve the effect of improving measurement accuracy, measurement accuracy and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

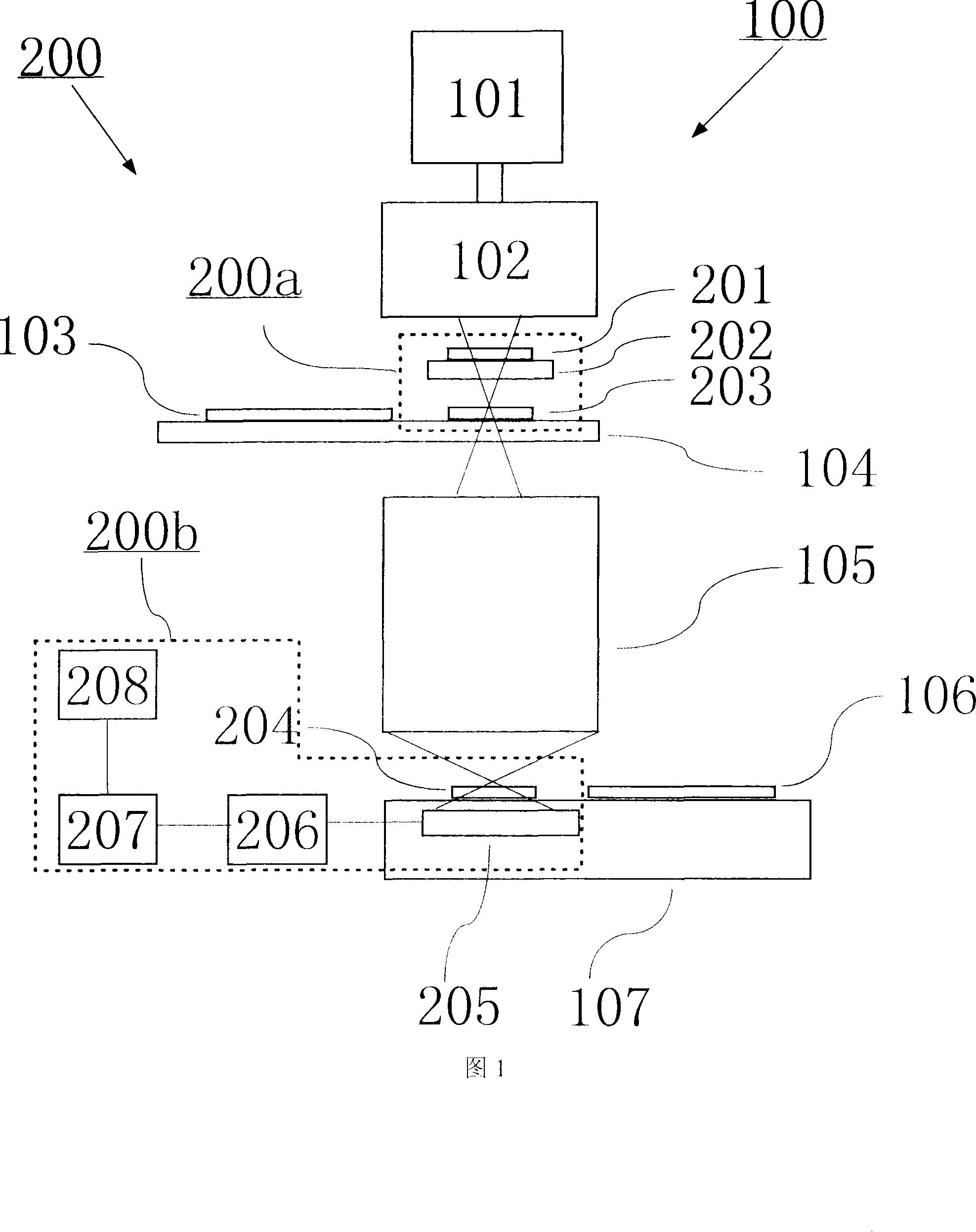

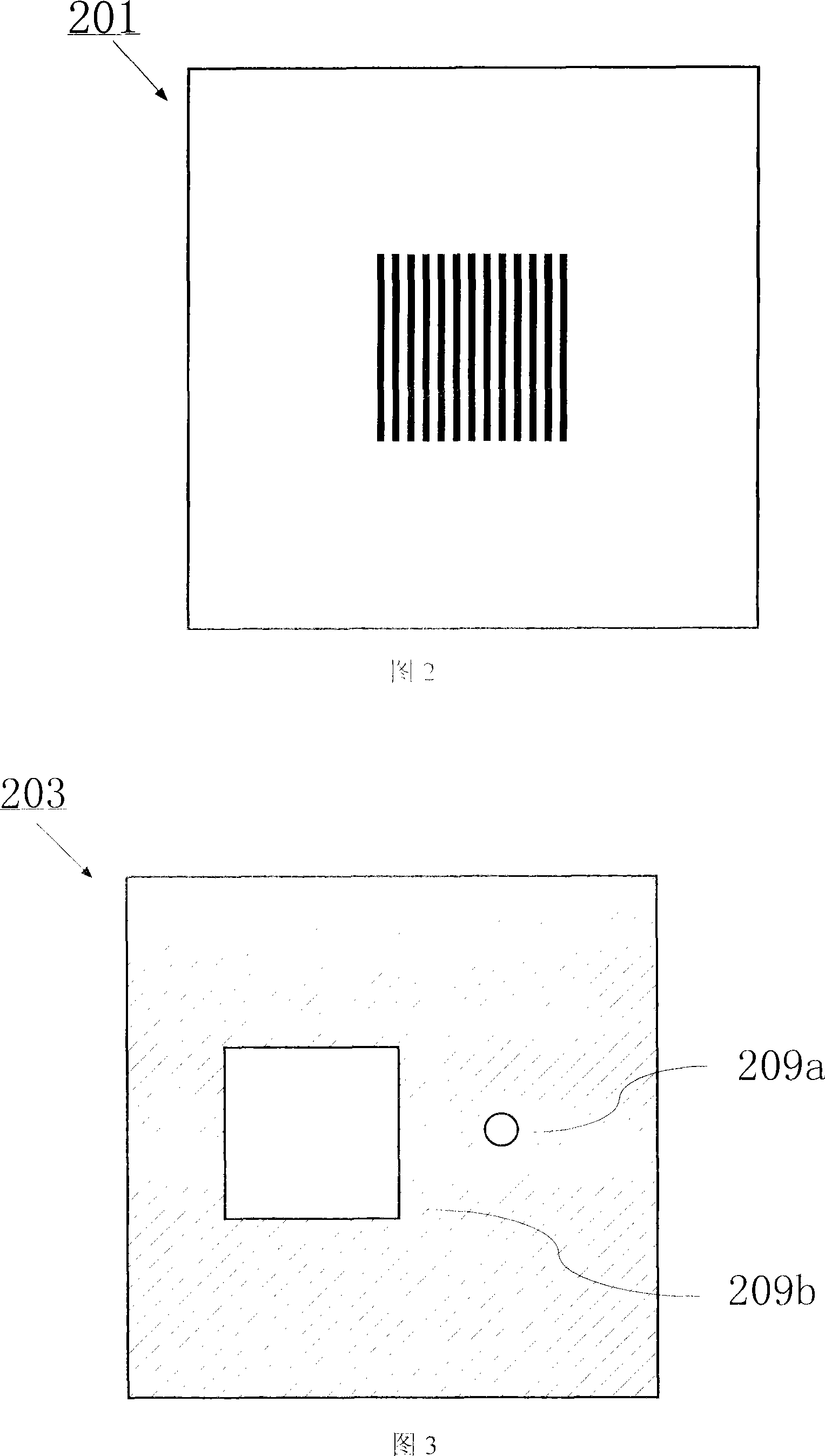

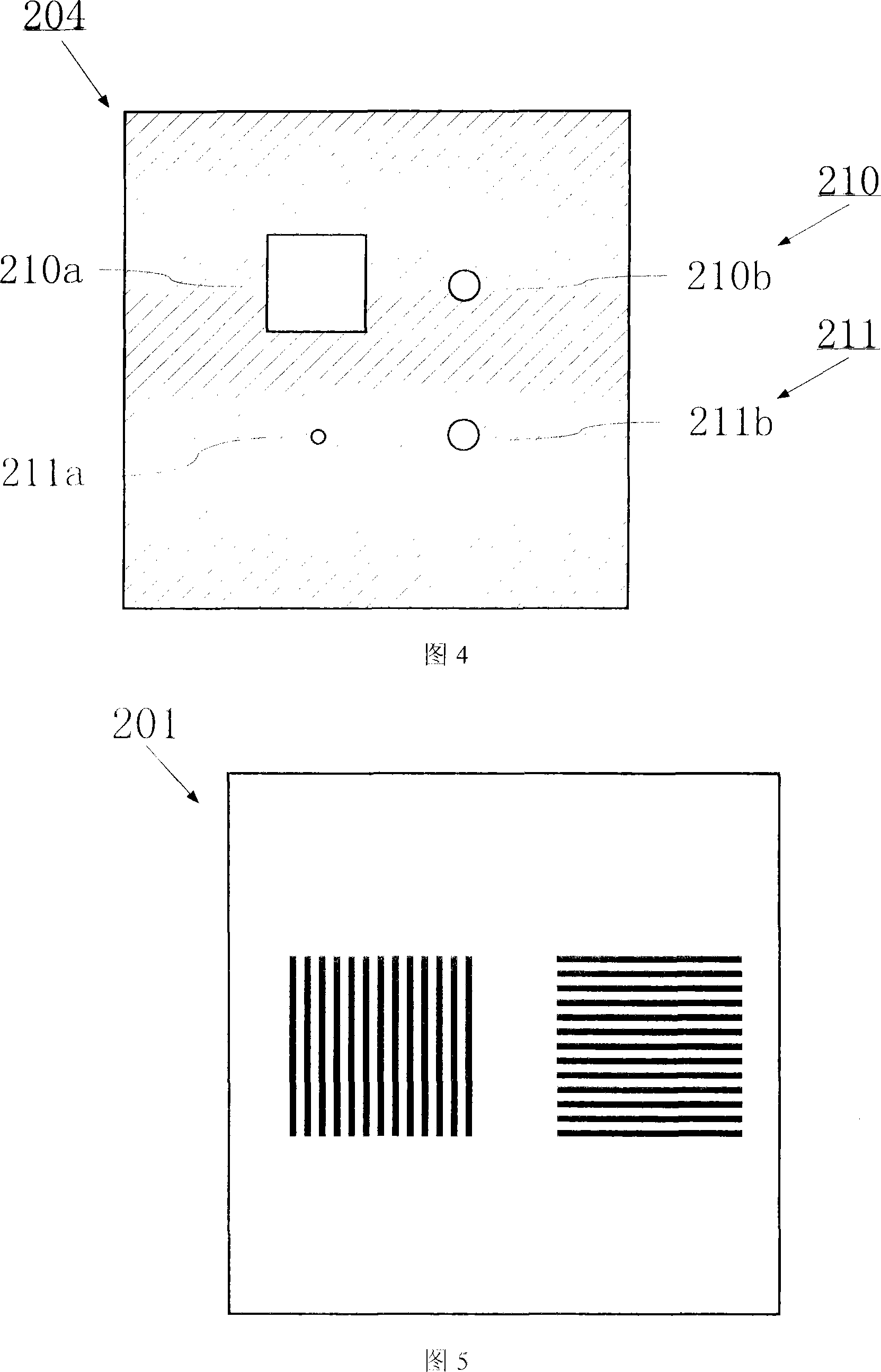

[0028] In this embodiment, an interferometer device 200 based on the principle of point diffraction interference is integrated on the lithography machine 100 to detect the wave aberration of the projection objective lens 105 online. As shown in FIG. 1 , the interferometer device 200 is structurally composed of two parts 200 a and 200 b : 200 a is integrated on the mask workpiece stage 104 , and 200 b is integrated on the silicon wafer workpiece stage 107 . The working principle of the interferometer device in this embodiment will be described below. The light beam emitted by the light source 101 is first shaped by the illumination system 102 and irradiated onto the beam splitting device 201. In this embodiment, the beam splitting device 201 is a binary grating prepared by electron beam exposure of a chromium mask, and the base material is fused silica. The light-shielding layer is metal chromium, and the chromium layer is engraved with a periodic structure with a duty ratio of...

Embodiment 2

[0059] In this embodiment, an interferometer device 200 based on the principle of slit diffraction interference is integrated on the lithography machine 100 to detect the wave aberration of the projection objective lens 105 online. The slit diffraction interferometer in this embodiment is similar in principle and structure to the point diffraction interferometer in Embodiment 1. The system error calibration method is similar to the wave aberration detection method. The differences are as follows.

[0060] In the principle of interferometer measurement, this embodiment uses a slit instead of the round hole in Embodiment 1, and uses the slit to diffract the output beam of the projection objective lens, and an ideal spherical wave is generated in the one-dimensional direction of space as a reference wave. The wave aberration of the projection objective lens is obtained by two measurements in the space orthogonal direction;

[0061] In terms of the structure of the interferometer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com