Method for preparing attapulgite loaded nano cerium oxide

A technology of nano-cerium oxide and attapulgite, which is applied in the field of preparation of attapulgite-loaded nano-cerium oxide, to achieve good dispersion, wide application value, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

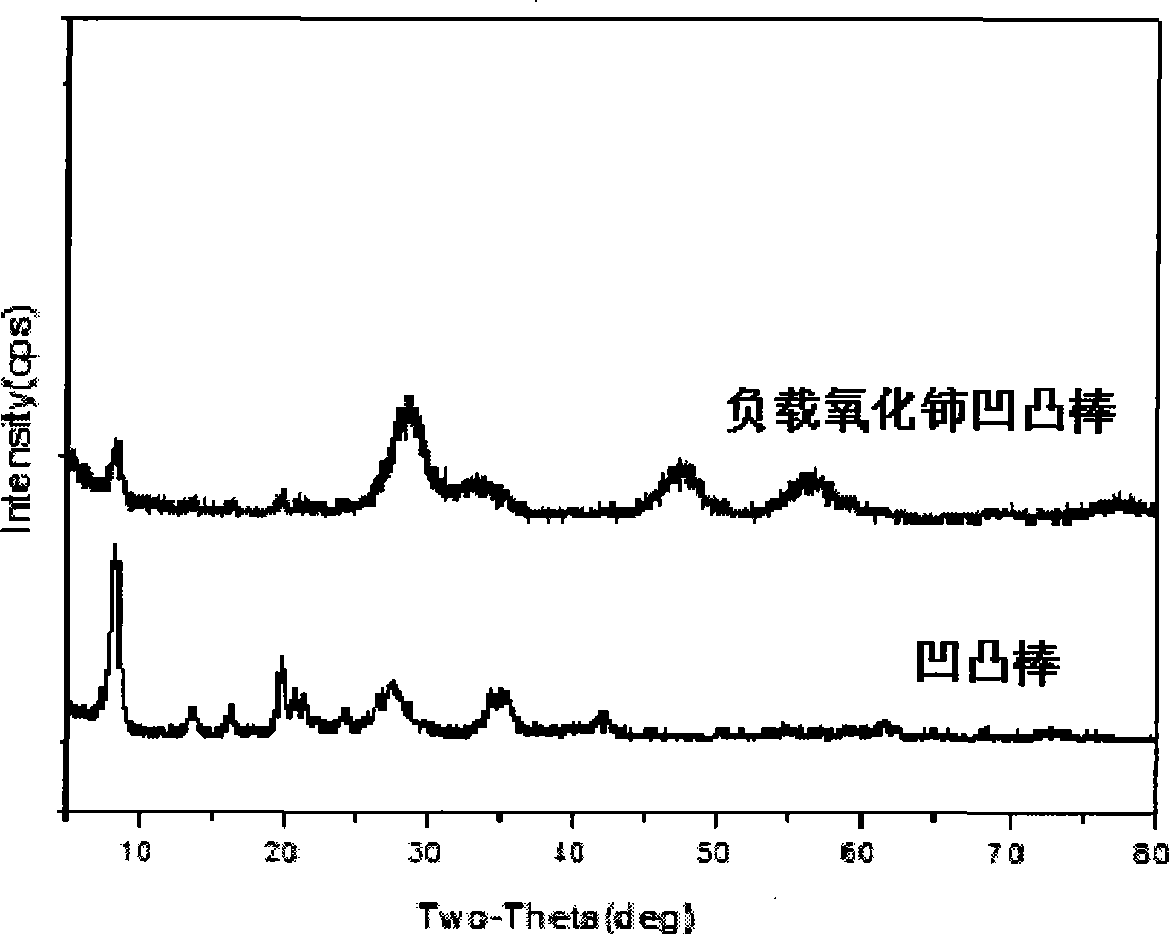

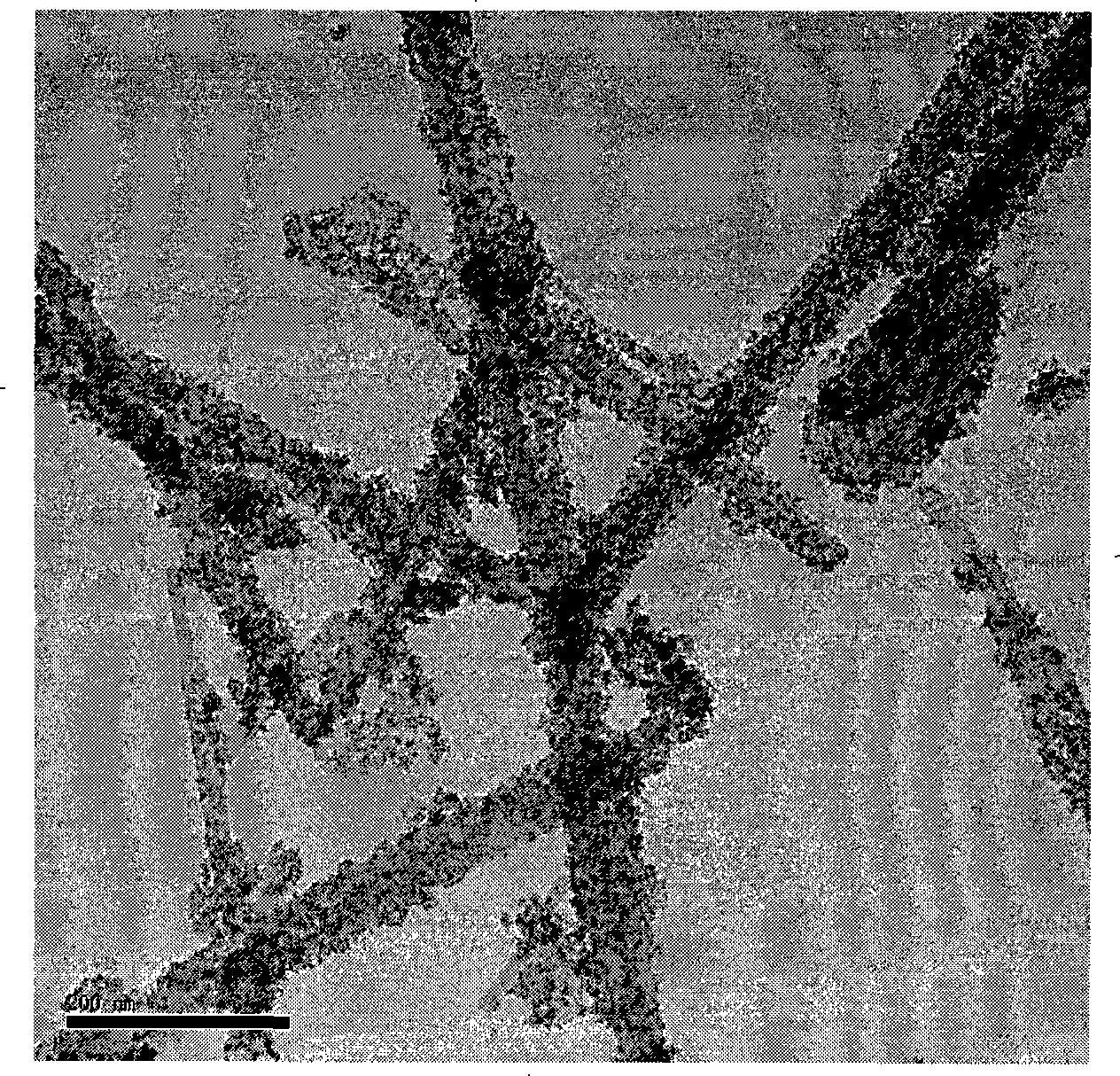

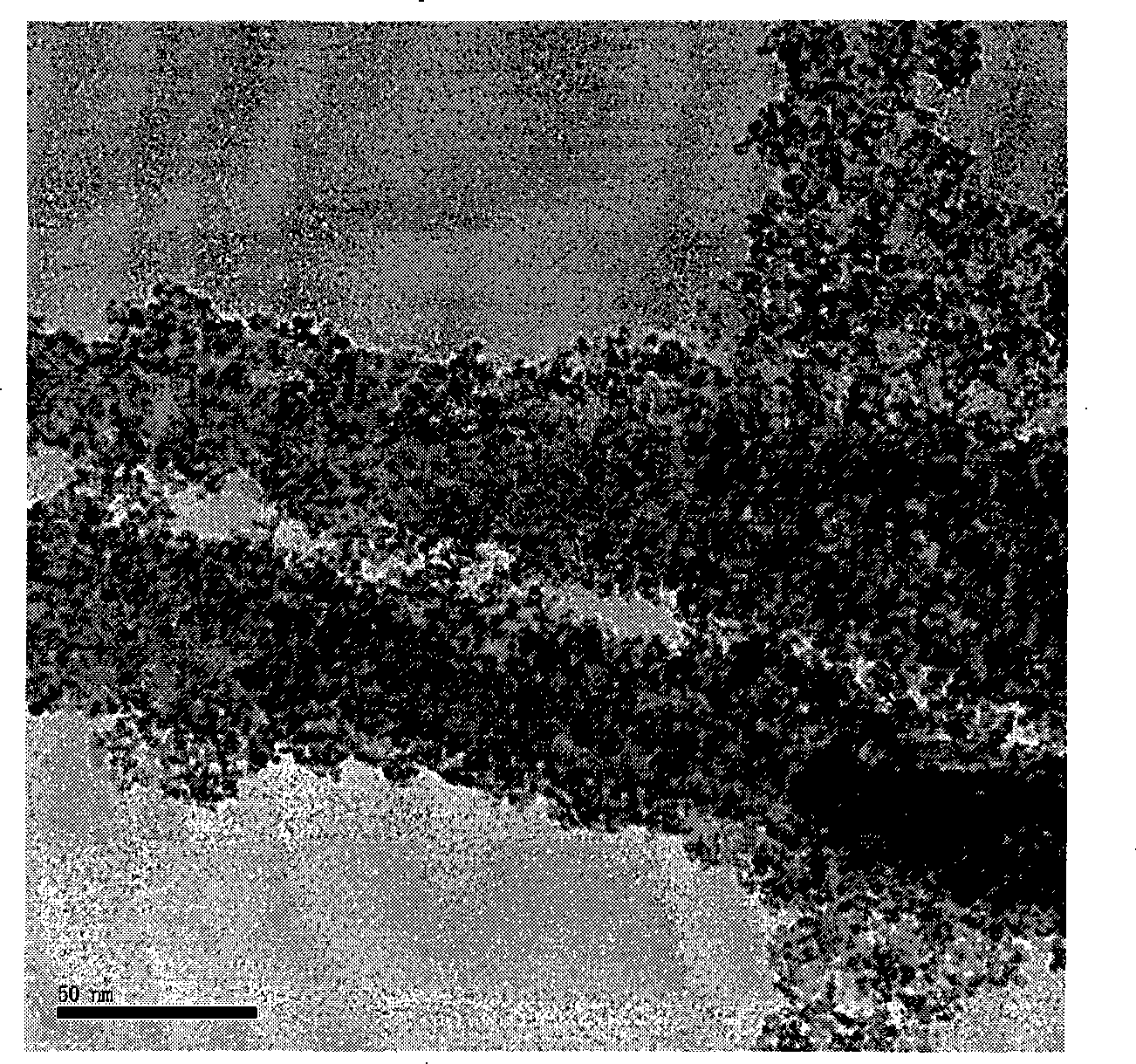

[0013] Embodiment 1: After the natural attapulgite clay is pretreated with hydrochloric acid, a slurry with a solid content of about 10% is made. Take 10 g of the slurry and add it to 90 ml of deionized water so that the concentration of the attapulgite is 10 g / l , then add Ce(NO 3 ) 3 0.005mol, making Ce 3+ The concentration relative to the solution is 0.05mol / l, stir the solution evenly with an electric stirrer, and then add the relative Ce 3+ About 0.025 mol of HMT with 5 times the molar amount was stirred evenly, and the mixed solution was stirred by an electric stirrer and placed in a water bath at 75°C for 2 hours, then taken out and cooled to room temperature, filtered, washed with deionized water for 3 times, and then Washed with absolute ethanol for 3 times, dried at 80°C, calcined at 200°C for 2h, and fully ground the sample after cooling to obtain attapulgite powder loaded with nano-cerium oxide. The X-ray powder diffraction experiment was carried out on the obt...

Embodiment 2

[0016] Embodiment 2: Change Ce(NO 3 ) 3 The addition amount of HMT was 0.01mol, the addition amount of HMT was 0.02mol, the concentration of the attapulgite was controlled at 2g / l, reacted in a water bath at 70°C for 3h, and then calcined at 300°C for 5h, and the subsequent detection was as in Example 1.

Embodiment 3

[0017] Embodiment 3: change Ce(NO 3 ) 3 The addition amount of HMT was 0.05mol, the addition amount of HMT was 1.0mol, the concentration of the attapulgite was controlled at 50g / l, reacted in a water bath at 100°C for 1h, and then calcined at 700°C for 5h, and the subsequent detection was as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com