Biomass stalk briquetting machine

A biomass straw and briquetting machine technology, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of high product density, high relative energy consumption, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

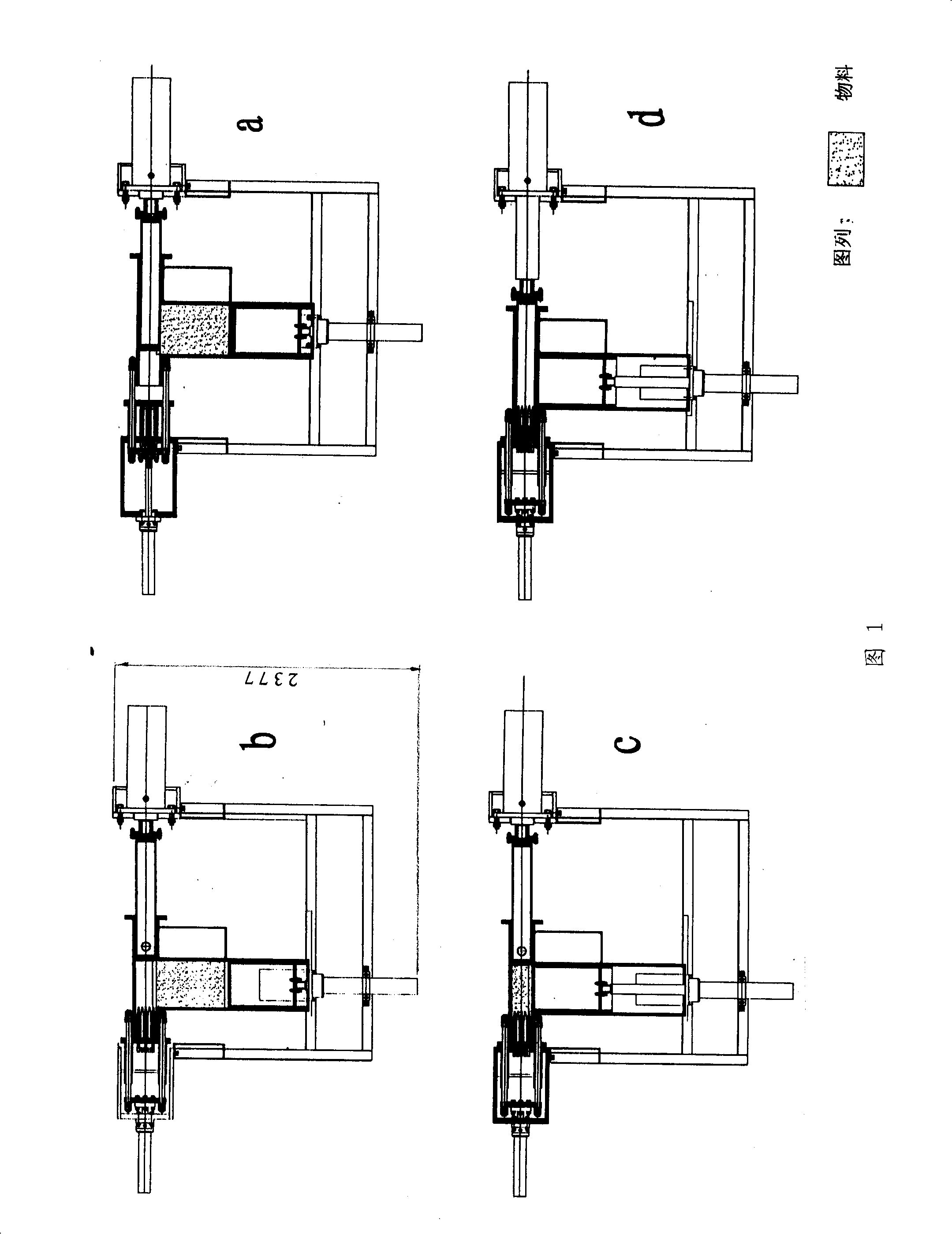

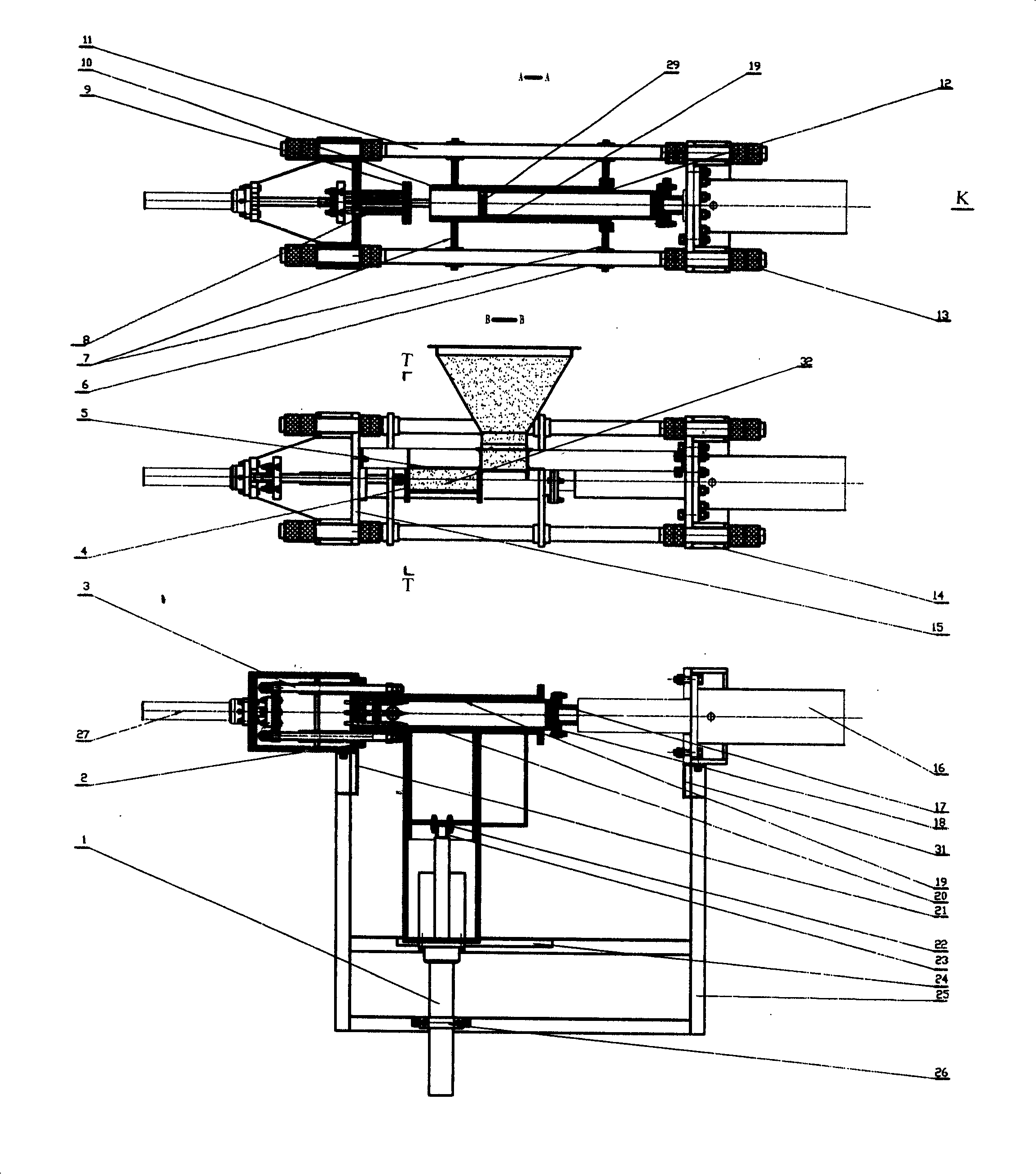

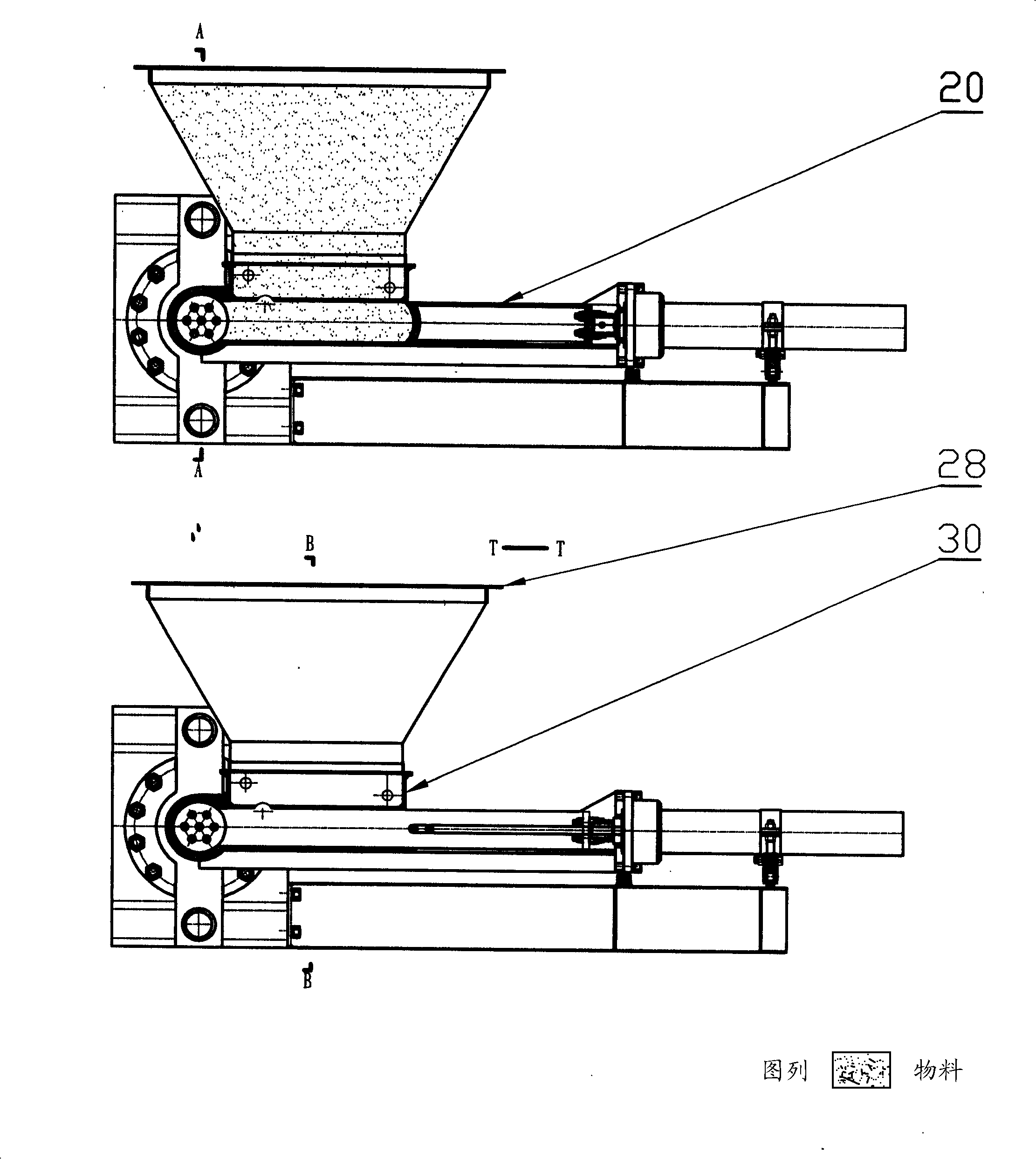

[0035] This machine adopts double units (left and right units), single oil cylinder bidirectional operation, eliminates non-working stroke, adopts large flow hydraulic pump, variable flow and constant power output, reduces no-load and light-load running time, high working performance, and effectively improves Improve the utilization rate of input energy and speed up the briquetting speed. In the case of constant input energy, the briquetting efficiency is increased by 1.5 times, and the energy consumption per ton is reduced by 50% compared with the forming machine with open mold structure.

[0036] The power system of this machine selects a motor with a power of 25-30kw and a speed of 1450r / min, and drives a variable flow hydraulic pump with a displacement of 160-250mL per revolution, and performs constant power output under pressure control. Corresponding hydraulic valves and oil tanks are selected from common standard parts to form the pumping station system, which will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com