Method for coating fluoroparylene and special coating device

A technology of p-xylene and coating equipment, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., and can solve the problems of high penetration ability, high requirements for hardware coating equipment, and low permeability. Achieve the effects of reducing costs, simplifying coating equipment, and reducing transitional carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

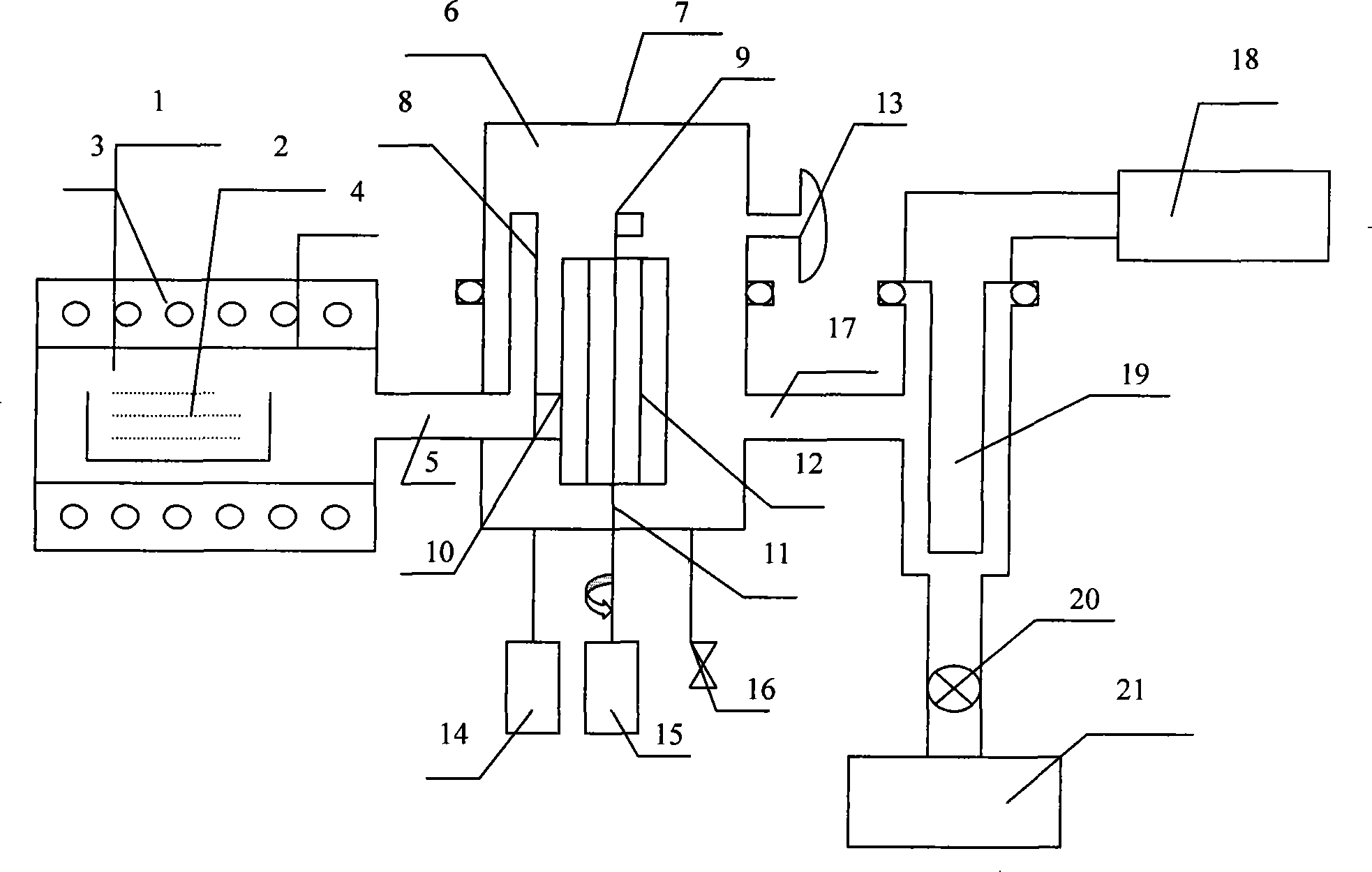

[0033] Referring to the accompanying drawings, the fluorinated parylene coating improvement equipment includes a gasification cracking chamber 1, a polymerization deposition chamber 6, a cold trap 19, a throttle valve 20, a vacuum mechanical pump 21, and a refrigerator 18. The gasification and cracking chamber has a gasification boat 2, a stainless steel cracking chamber 4, and an electric heating tube 3 is installed outside the stainless steel cracking chamber. The gasification and cracking chamber communicates with the polymerization deposition chamber 6 through a pipeline 5.

[0034] The polymerization deposition chamber 6 has a vacuum bell jar 7, and the vacuum bell jar 7 is provided with a vacuum sealing ring and an observation window 13. A gas splitter 8 is arranged in the vacuum bell jar 7, and the inlet of the gas splitter is connected with the outlet of the connecting pipe of the gasification cracking chamber. , the gas splitter has a gas splitter barrel, the upper and...

Embodiment 2

[0046] Referring to the accompanying drawings, the fluorinated parylene coating improvement equipment includes a gasification cracking chamber 1, a polymerization deposition chamber 6, a cold trap 19, a throttle valve 20, a vacuum mechanical pump 21, and a refrigerator 18. The gasification and cracking chamber has a gasification boat 2, a stainless steel cracking chamber 4, and an electric heating tube 3 is installed outside the stainless steel cracking chamber. The gasification and cracking chamber communicates with the polymerization deposition chamber 6 through a pipeline 5.

[0047] The polymerization deposition chamber 6 has a vacuum bell jar 7, and the vacuum bell jar 7 is provided with a vacuum sealing ring and an observation window 13. A gas splitter 8 is arranged in the vacuum bell jar 7, and the inlet of the gas splitter is connected with the outlet of the connecting pipe of the gasification cracking chamber. , the gas splitter has a gas splitter barrel, the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com