Technique for synthesizing and purifying sucrose trichloride

A synthesis process, the technology of sucralose, applied in the field of synthesis and purification process of sucralose, can solve the problems of high production cost, cumbersome process, unfavorable application, etc., achieve high conversion rate and purity, mild reaction conditions, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

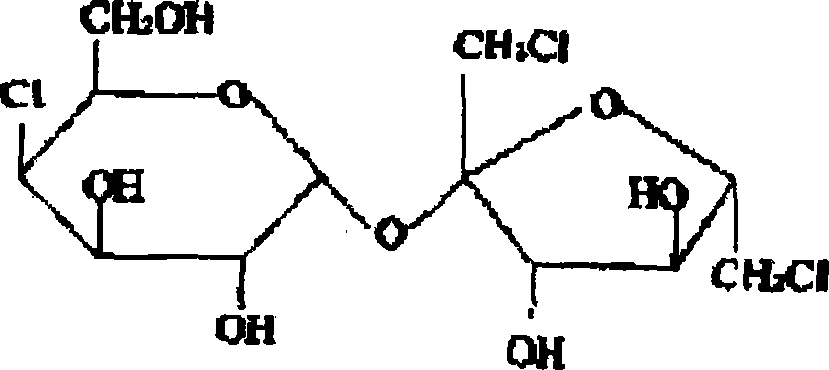

Image

Examples

Embodiment Construction

[0040] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0041] Synthesis of Sucrose-6-Acetate

[0042] Add 100g sucrose, 350ml N, N-dimethylformamide, 100ml cyclohexane, 2g catalyst (sodium acetate: DMAP=0.5: 1.5) in a 1000ml four-neck flask, heat to reflux, and dehydrate for 3 hours under stirring , then cooled to 25°C, added dropwise 40g of acetic anhydride, and then incubated for 5 hours, filtered to recover the catalyst, and the mother liquor was decompressed to recover DMF to obtain 108g of syrup. Ester 90.2%.

[0043] Synthesis of Sucralose-6-Acetate

[0044] Take the above 108g syrup and dissolve it with 500ml N,N-dimethylformamide for later use, add 500ml N,N-dimethylformamide into a 2000ml four-necked bottle, cool to -10°C, add 300ml thionyl chloride dropwise, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com