Treatment method of missile propellant waste water and mobile processing vehicle

A treatment method and propellant technology, applied in the field of propellant wastewater treatment, can solve the problems of difficult maintenance and management, secondary pollution, complicated operation, etc., and achieve the effects of reliable technology, maintaining integrity and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

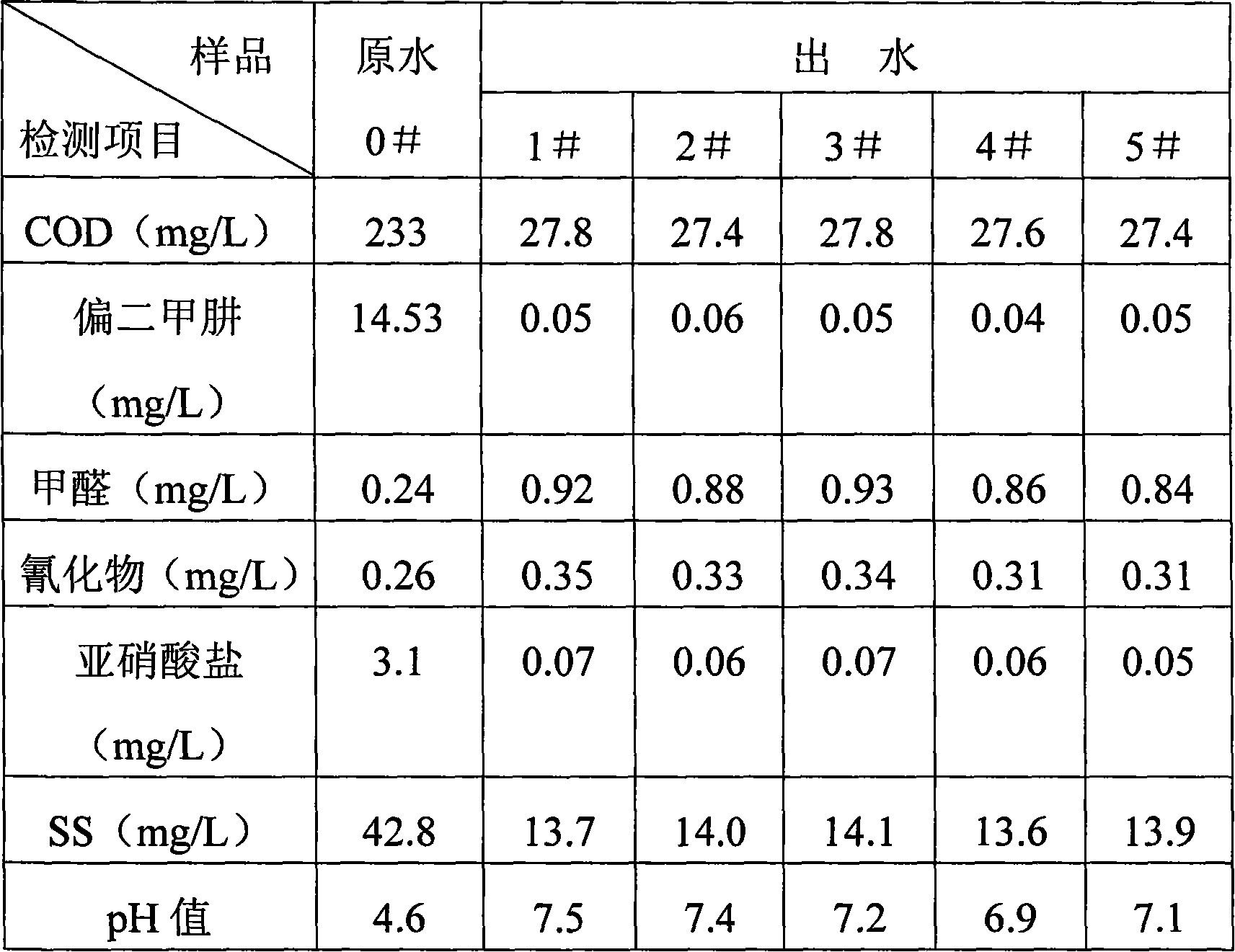

[0043] Embodiment 1 is used for processing launch site laboratory propellant waste water

[0044] Before the launch of the rocket or satellite, it is necessary to test the filled propellant. During the test, the laboratory propellant waste water will be generated by cleaning the test instruments. The waste water is collected in the underground waste water storage tank near the laboratory. It is characterized by high wastewater concentration, high acidity, and long storage time. Most of unsymmetrical dimethylhydrazine is converted into various intermediate products. Generally, COD reaches 200-250mg / L, unsymmetrical dimethylhydrazine concentration is about 10-25mg / L, and pH value is about 3.5~5.0.

[0045] When using a mobile propellant wastewater treatment vehicle to treat laboratory wastewater, first drive the treatment vehicle to the vehicle operation field near the wastewater storage tank. After the car stops, connect the water inlet pipe, water outlet pipe, air outlet pipe...

Embodiment 2

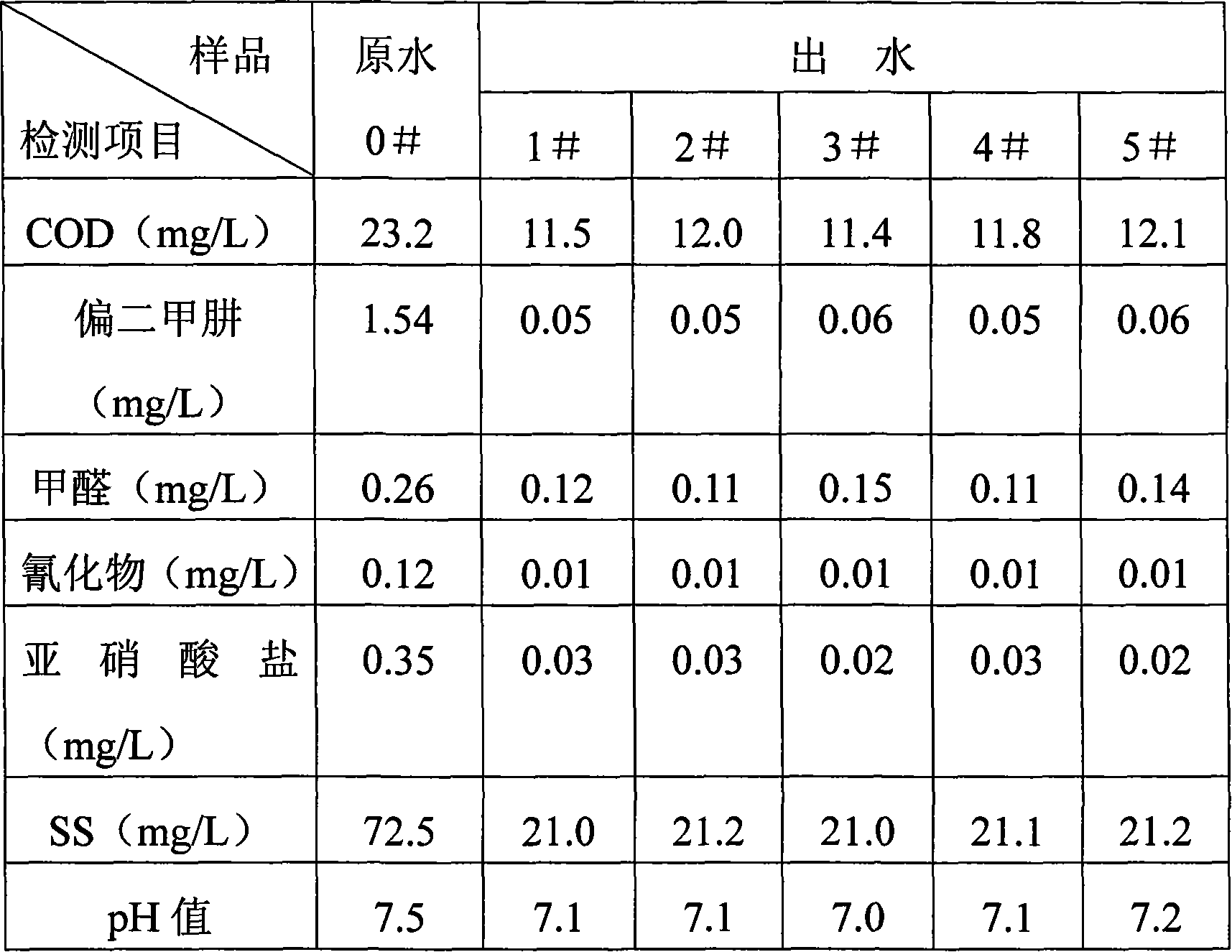

[0048] Embodiment 2 is used to treat the propellant wastewater of the diversion tank of the launch site

[0049] Before the launch of the rocket, a large amount of water will be injected into the diversion tank to reduce the temperature of the diversion tank during launch. After launch, there will be waste water that has absorbed the launch exhaust. The water spray cooling system during launch and the launch tower after launch Washing also introduces residual propellant into the diversion tank wastewater. The wastewater from the diversion tank is characterized by a large amount of water and low concentration of pollutants. Generally, the COD is only 10-50 mg / L.

[0050] When a mobile propellant wastewater treatment vehicle is used to treat diversion tank wastewater, the operation steps are the same as in Example 1, and a water sample (0#) is taken to detect the wastewater quality. The results are shown in Table 3. According to the quality of wastewater, select operation mode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com