Preparation method of benzaldehyde

A technology of benzaldehyde and cinnamaldehyde, applied in the direction of ozonolysis preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of strict control of reaction temperature, reduction of natural degree of benzaldehyde, ozone Problems such as low utilization rate, to achieve the effect of low equipment requirements, high naturalness, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

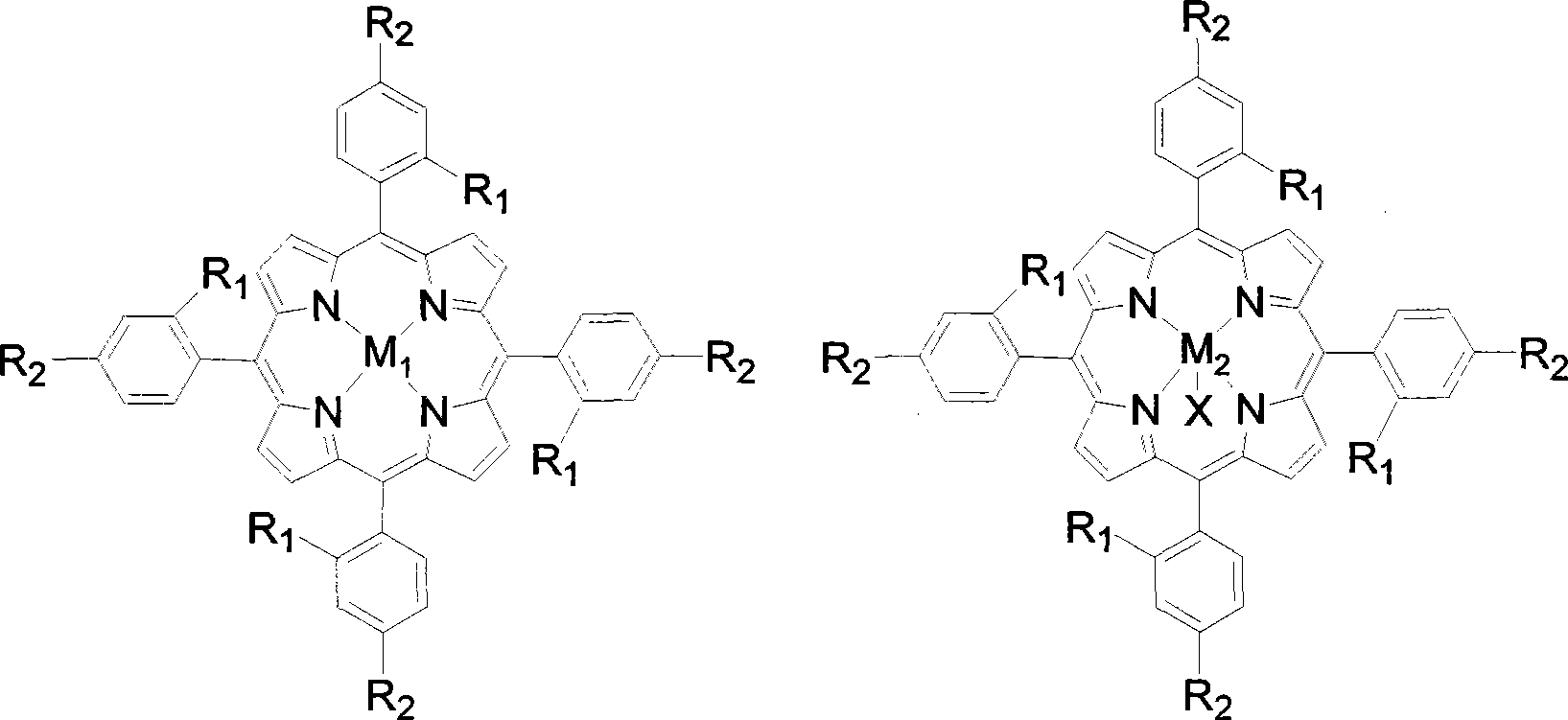

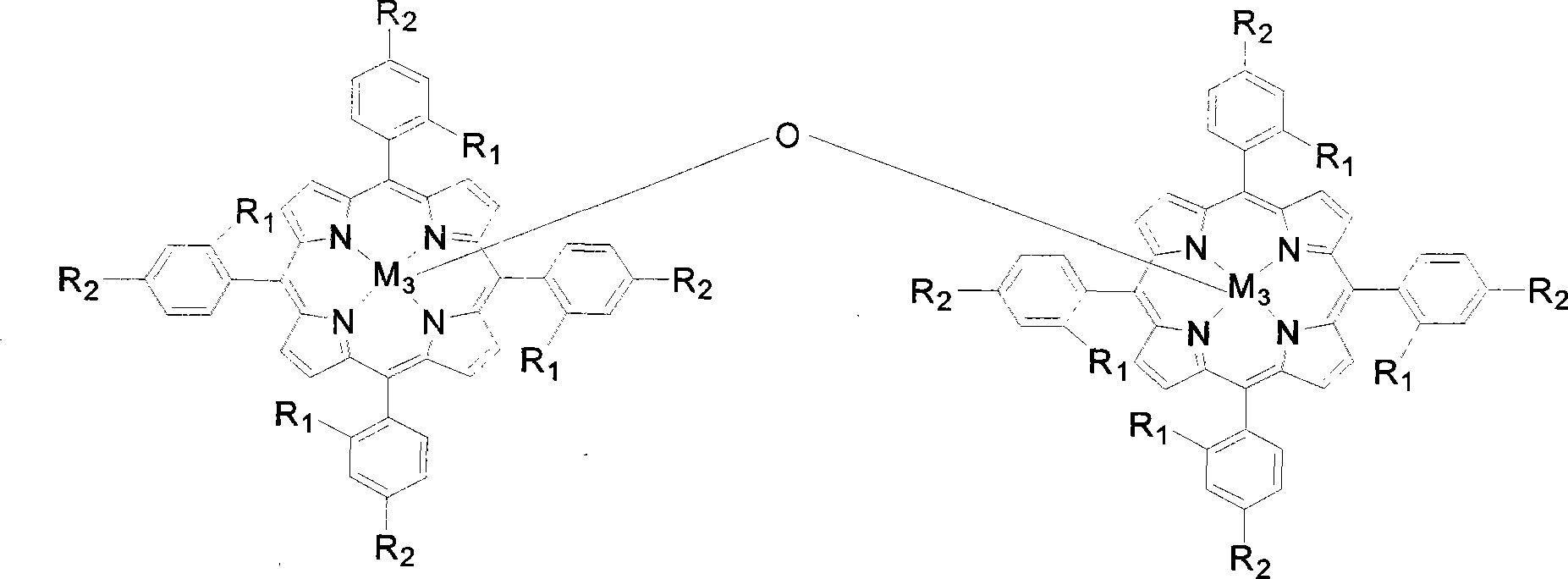

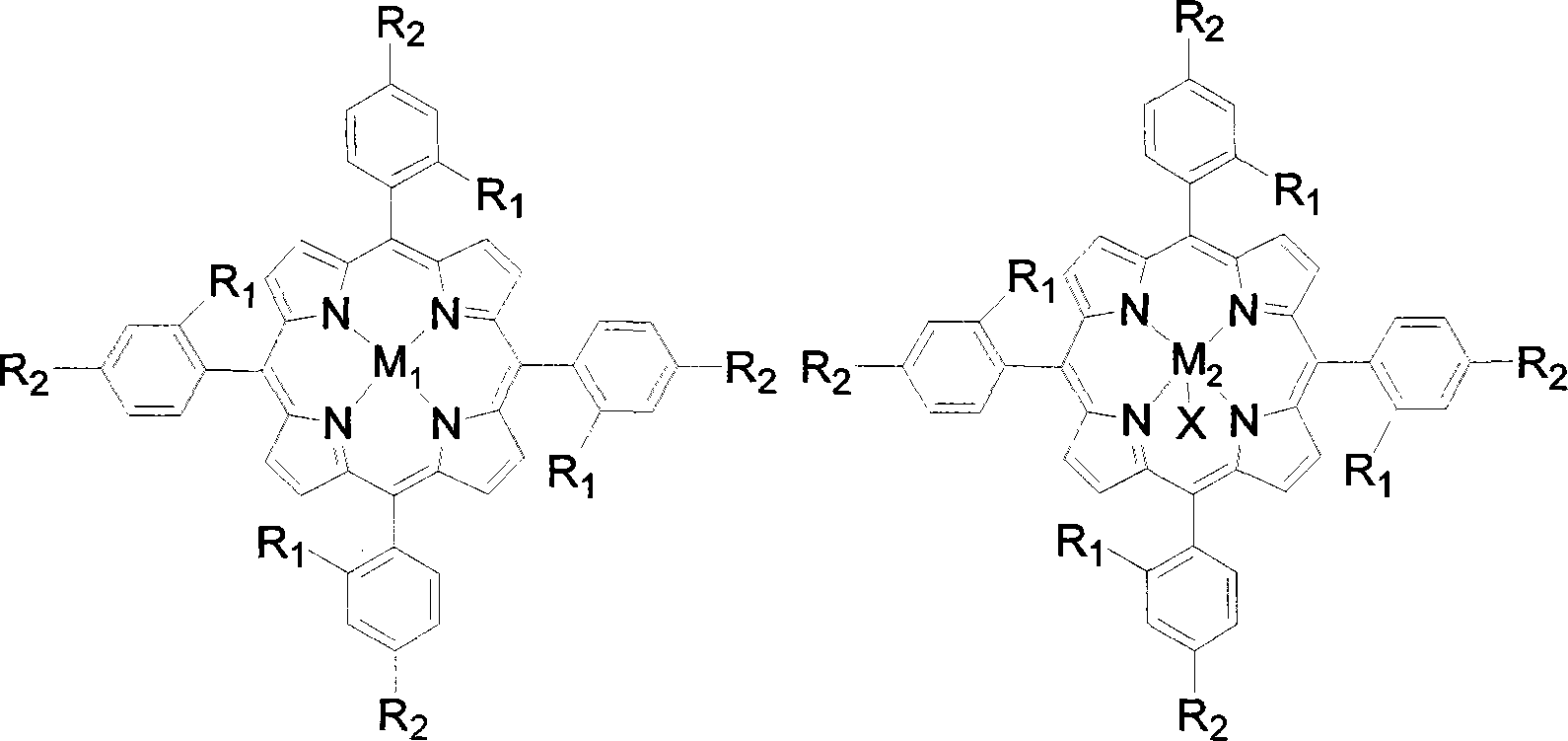

[0020] Contains 2 x 10 in 5 mL -5 Four-(ortho-nitrophenyl) manganese porphyrin catalyst of mol / L (i.e. R in the general formula (I) 1 = NO 2 , R 2 = H, M 1 =Mn) in the benzene solution, add the cinnamaldehyde of 1mmol and the isobutyraldehyde of 1mmol, pass into the oxygen of 0.2MPa, at 30 ℃ with the stirrer speed of 600 revs / min after stirring the reactant for 12 hours, through gas chromatography analysis, The conversion rate of cinnamaldehyde was 65%, and the yield of benzaldehyde was 30%. The reaction only needs to be carried out in a temperature-controlled reactor, while the ozonation method requires an ozone generator and a bubbling reactor, and after the ozonation is completed, it is necessary to add thiourea aqueous solution to reduce the ozonated intermediate. quite complicated.

Embodiment 2

[0022] Contains 2 x 10 in 5 mL -4 The four-(p-chlorophenyl) iron porphyrin catalyst of mol / L (being R in the general formula (I) 1 = H, R 2 =Cl,M 1 =Fe) in the toluene solution, add 1mmol of cinnamaldehyde and 3mmol of isobutyraldehyde, feed the oxygen of 0.5MPa, stir the reactant at 60°C with a stirring speed of 600 rev / min for 6 hours, analyze by gas chromatography, The conversion rate of cinnamaldehyde was 75%, and the yield of benzaldehyde was 40%.

Embodiment 3

[0024] Contains 2 x 10 in 5 mL -3 The four-(ortho-methylphenyl) cobalt porphyrin catalyst of mol / L (being R in the general formula (I) 1 =CH 3 , R 2 = H, M 1 =Co) in the acetonitrile solution, add 1mmol of cinnamaldehyde and 5mmol of isobutyraldehyde, feed 1.0MPa of oxygen, stir the reactant at 60°C with a stirring speed of 600 rev / min for 4 hours, analyze by gas chromatography, The conversion rate of cinnamaldehyde was 80%, and the yield of benzaldehyde was 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com