Method for extracting high-pure shikimic acid from scarlet octagonal fruit

A shikimic acid, high-purity technology, applied in the direction of pharmaceutical formulations, separation/purification of carboxylic acid compounds, medical preparations containing active ingredients, etc., can solve problems such as containing alkali and consuming large acidic cationic resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

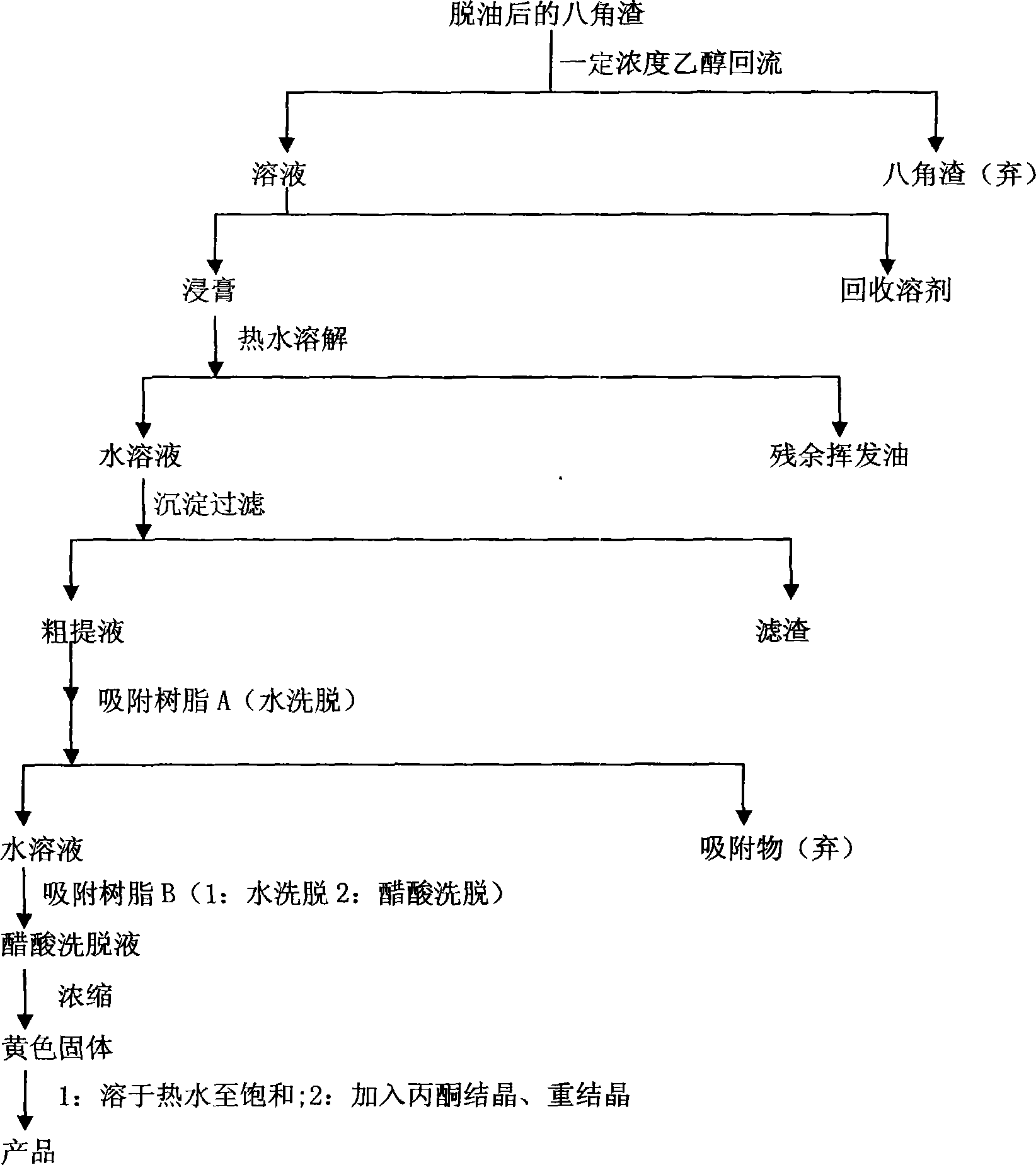

Method used

Image

Examples

Embodiment 1

[0027] Take 500 grams of dried star anise fruit powder and crush it to 30-40 meshes, use 1.5 L of petroleum ether (boiling range: 60°C-90°C) as a solvent, use a reflux device to reflux extract for 3 hours, and then vacuum separate it under the condition of 60-90°C The star anise oleoresin is deoiled star anise slag, and the star anise slag is dried in the air. Reflux the dried star anise slag with 1.5L, 1.25L, 1.0L, 1.0L of 85% ethanol for 3, 3, 2.5, 2 hours respectively, combine the extracts and concentrate in vacuo to a density of 1.3-1.4g / mL extract. Dissolve the obtained extract in 5 times the volume of hot water and heat at about 78°C for about one hour, remove a small amount of grease from the upper layer, cool, precipitate, and filter to obtain an orange-red liquid. The obtained liquid is subjected to column chromatography with 400 g of neutral macroporous adsorption resin 201*7 (type 717) that has been treated, and is eluted with water to a light color, and the eluate...

Embodiment 2

[0029]Take 800g of dried red star anise fruit powder and crush it to 30-40 meshes, use 2.2L of petroleum ether (boiling range: 60°C-90°C) as a solvent, and use a reflux device to reflux for 3 hours, and then vacuum-separate the star anise under the condition of 60-90°C Oleoresin obtained deoiled star anise slag, and the star anise slag was air-dried, and the dried star anise slag was refluxed with 2.4L, 2.0L, 1.6L, 1.6L 85% ethanol for 3, 3, 2.5 , 2 hours, the combined extracts were vacuum concentrated to an extract with a density of 1.3-1.4 g / mL. Dissolve the obtained extract in 7 times the volume of hot water and heat at about 80°C for about one hour, remove a small amount of grease from the upper layer, cool, precipitate, and filter to obtain an orange-red liquid. The obtained liquid is subjected to column chromatography with 560 g of neutral macroporous adsorption resin 201*7 (type 717) that has been treated, eluted with water to a light color, and the eluate is collected ...

Embodiment 3

[0031] Take 1Kg of dried star anise fruit powder and crush it to 30-40 meshes, use 3.2L of petroleum ether (boiling range: 60°C-90°C) as a solvent, and use a reflux device for reflux extraction for 3 hours, and then vacuum-separate the star anise under the condition of 60-90°C Oleoresin is deoiled star anise slag, and the star anise slag is dried in the air. Reflux the dried star anise slag with 3.0L, 2.5L, 2.0L, and 2.0L of 80% ethanol for 3, 3, 2.5, and 2 hours respectively, combine the extracts and concentrate in vacuum to a density of 1.3-1.4g / mL extract. Dissolve the obtained extract in 6 times the volume of hot water and heat at about 76°C for about one hour, remove a small amount of grease from the upper layer, cool, precipitate, and filter to obtain an orange-red liquid. The resulting liquid is subjected to column chromatography with 600 g of neutral macroporous adsorption resin 201*7 (type 717) that has been treated, eluted with water to a light color, and the eluate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com