Soybean oil based intaglio printing ink and bonding material thereof

An ink connecting material and connecting material technology, applied in the directions of ink, printing, printing device, etc., can solve the problems of harmful pollution of the air and the surface of the printed matter, endangering the health of the manufacturer and the user, etc. Cleaning performance, cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

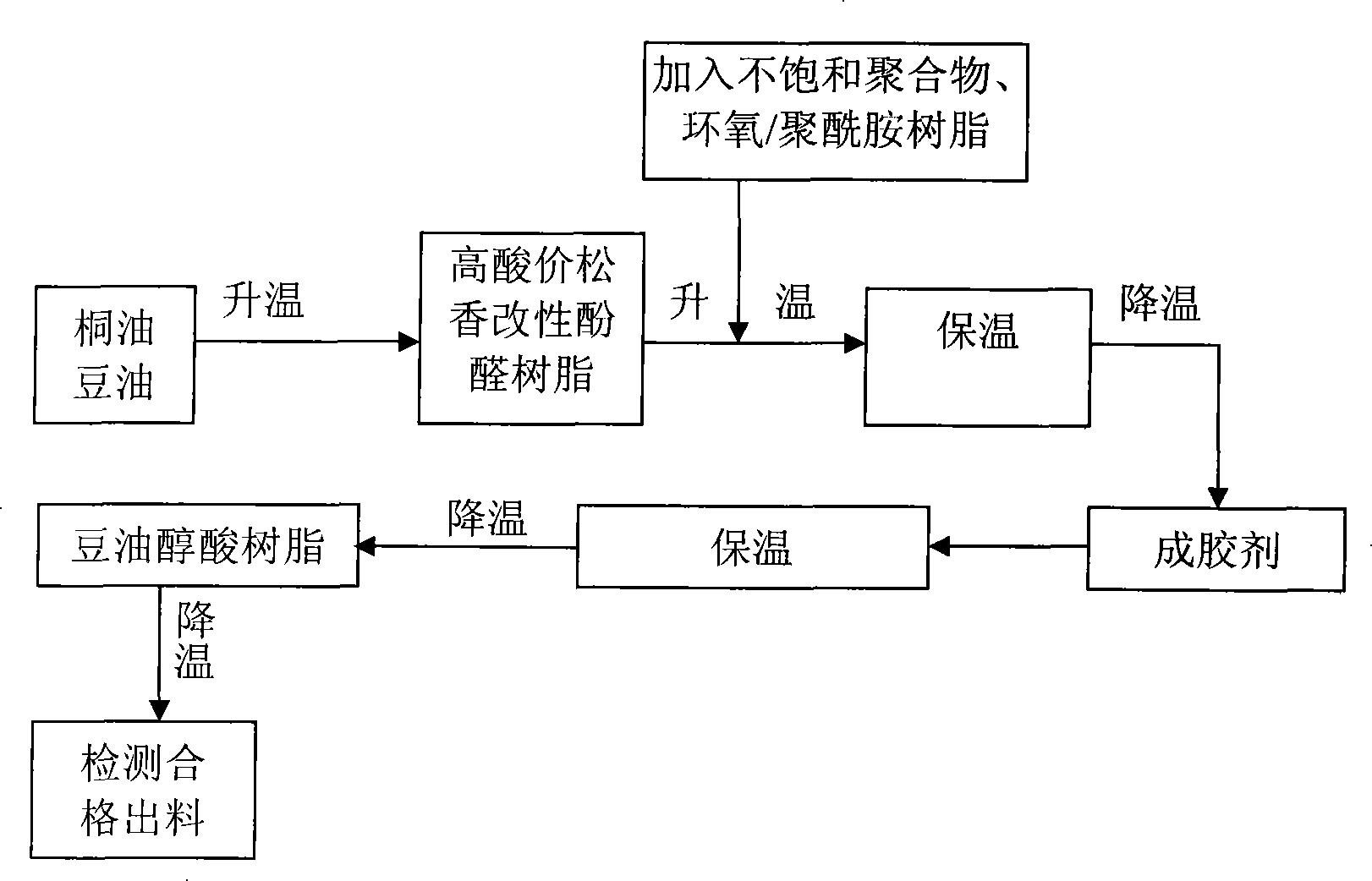

Method used

Image

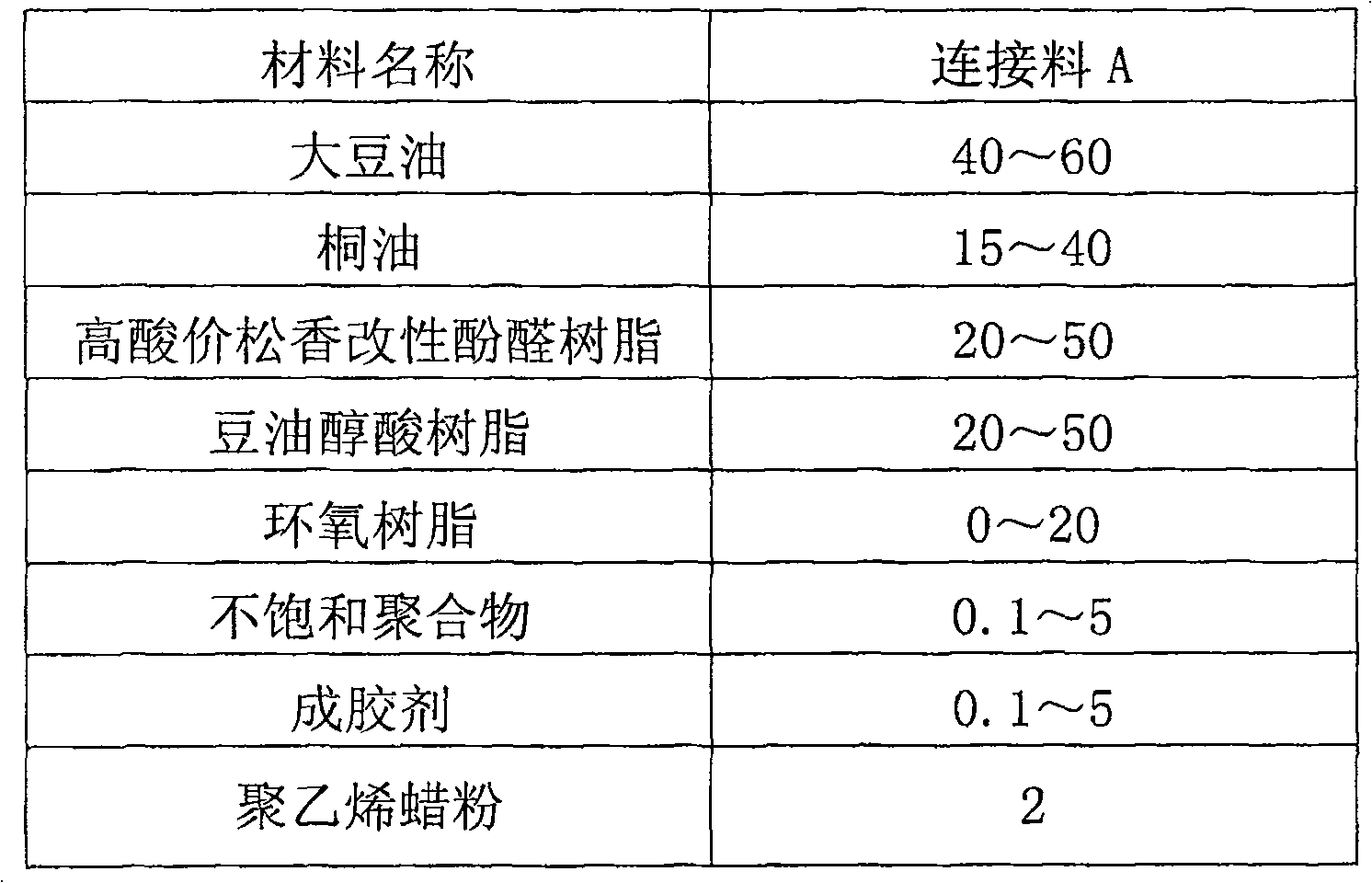

Examples

example 2

[0058] Binder B formula example 2 (by weight):

[0059]

example 3

[0060] Binder B formula example 3 (by weight):

[0061]

[0062] The technical indicators of binder B are as follows: viscosity 10-14PaS / 40℃.

[0063] The unsaturated polymer may be a low molecular weight polymer such as polyisobutylene, polybutadiene, polyisoprene, polyhexene, polyheptene, or a copolymer of two of them. Polybutadiene is recommended.

[0064] The phenol used in the phenolic resin can be selected from phenol, bisphenol A, butanol etherified cresol, phenol+cresol, p-tert-butylphenol, p-tert-octylphenol, diphenolic propane, p-1-t-octylphenol, p-1 Nonylphenol, p-dodecylphenol, etc. can be used alone or in combination, and p-nonylphenol formaldehyde novolac resin is recommended.

[0065] The phenol used in high acid value rosin modified phenolic resin can be selected from phenol, bisphenol A, butanol etherified cresol, phenol+cresol, p-tert-butylphenol, p-tert-octylphenol, diphenolic propane, One of octylphenol, p-nonylphenol, p-dodecylphenol, etc. or in comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com