Modelling method for dimethylbenzene oxidation reaction industry device model

A technology of p-xylene and modeling methods, applied in adaptive control, instruments, control/regulation systems, etc., can solve problems such as difficult to obtain, limited experimental data, and easy models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The description of the following embodiments will help understand the present invention, but does not limit the content of the present invention.

[0071] The following examples further illustrate the present invention:

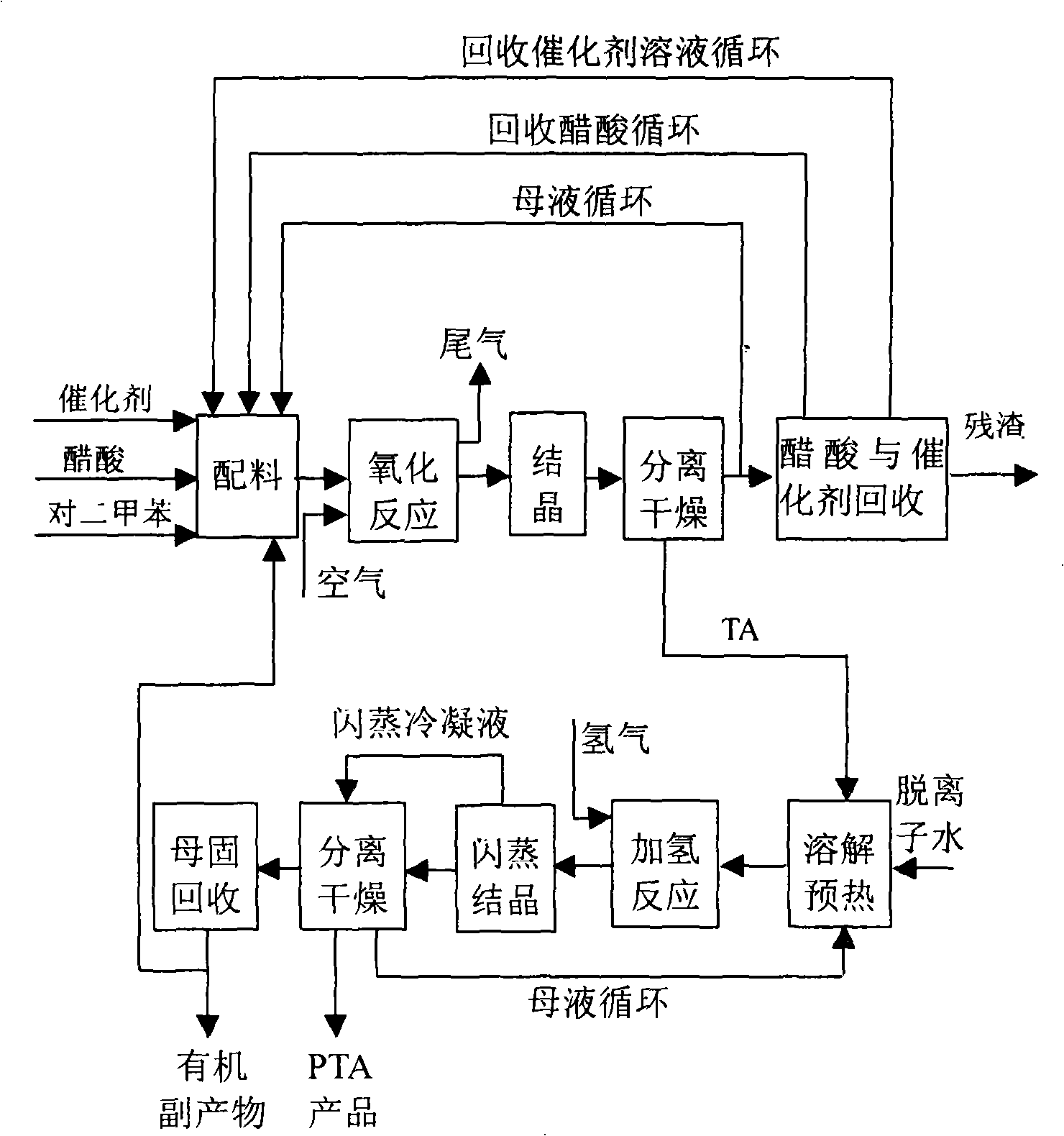

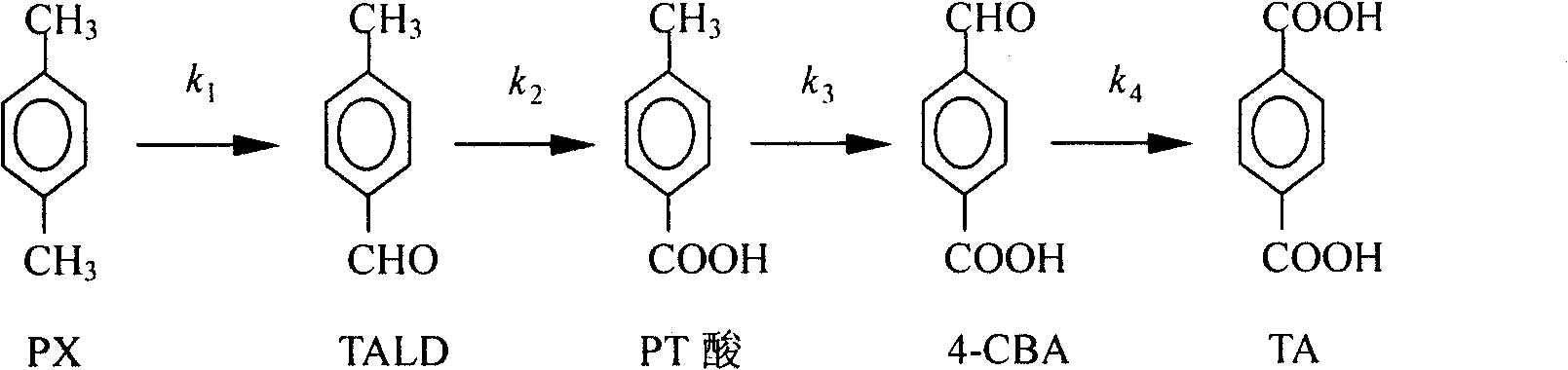

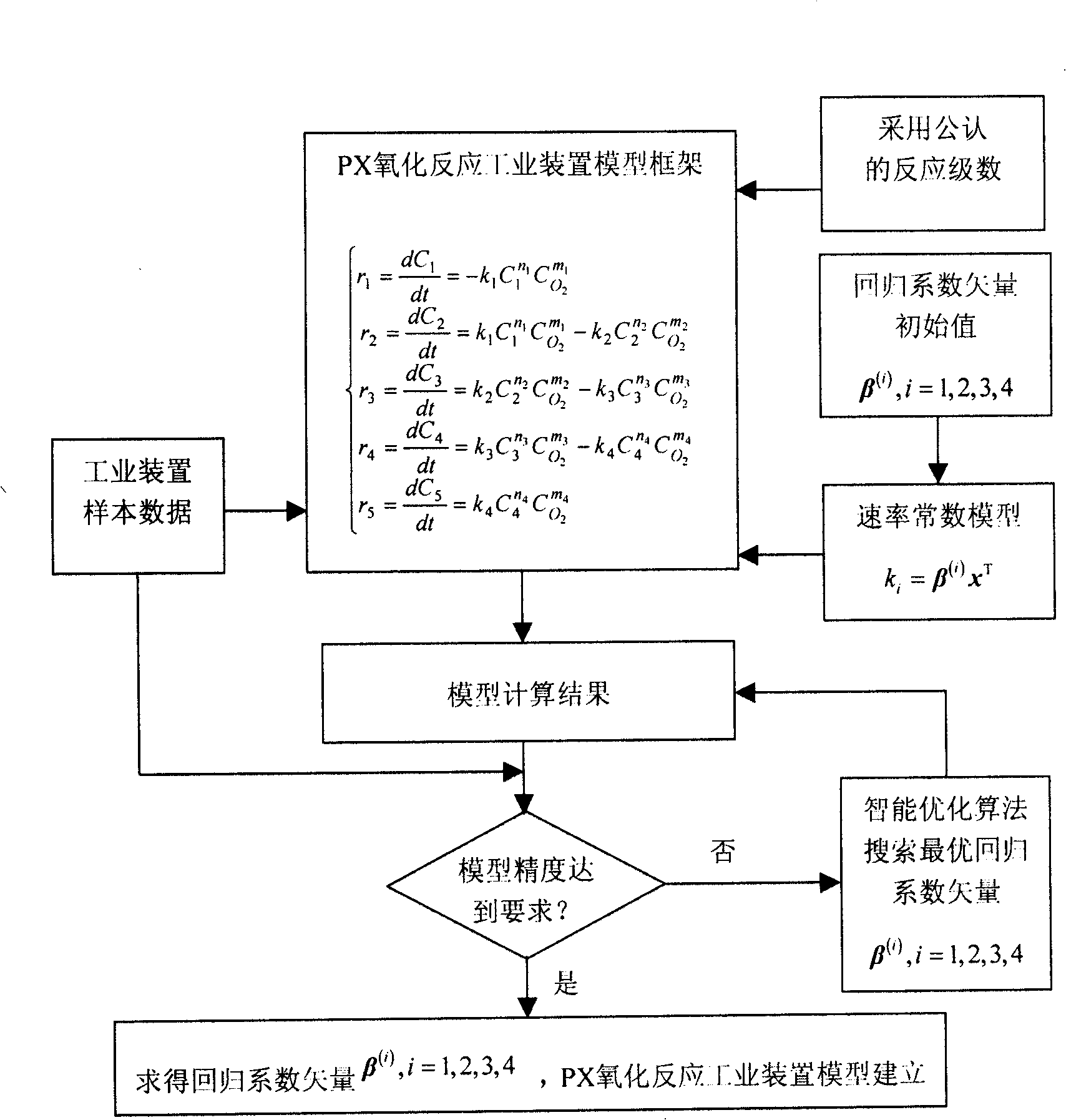

[0072] Such as figure 1 The PX oxidation reaction takes p-xylene as the raw material, acetic acid as the solvent, and under the action of cobalt acetate and manganese acetate catalysts, hydrogen bromide is used as a promoter to react with oxygen in the air to generate terephthalic acid. Consider important intermediate components and final reaction products, using such as figure 2 As shown in the reaction network, the reaction rate equation (1) of each component is established. The establishment of the PX oxidation reaction industrial device model, that is, the identification of model regression parameters such as image 3 As shown, the specific implementation steps are as follows:

[0073] Suppose, for the rate constant correlation model, add the m=2 orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com