Medicament carrying microballoons of hydrophobic nature medicament and method of preparing the same

A hydrophobically modified, gel microsphere technology, applied in the field of gel microsphere synthesis and drug embedding materials, can solve the problems of harsh reaction conditions, low reactivity, affecting gelling performance, etc., and achieves drug loading capacity. Improve, the synthesis steps are simple, and the effect of slow release is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a single-necked flask covered with aluminum foil, prepare a sodium alginate (SA) solution (2% w / v, 250mL), add a certain amount of sodium periodate, seal it and stir it with magnetic force, react for 24 hours, add 1mL of ethylene glycol Alcohol terminates the oxidation reaction for 15 minutes, and it is very important to avoid light for this process. The resulting mixed solution was fully dialyzed and freeze-dried, and the oxidized sodium alginate ( OSA). The amount of sodium periodate added to 250 mL of the above 2% w / v sodium alginate solution is 0-0.022 mol, then oxidized sodium alginate with an oxidation degree of 0-62.4% can be obtained.

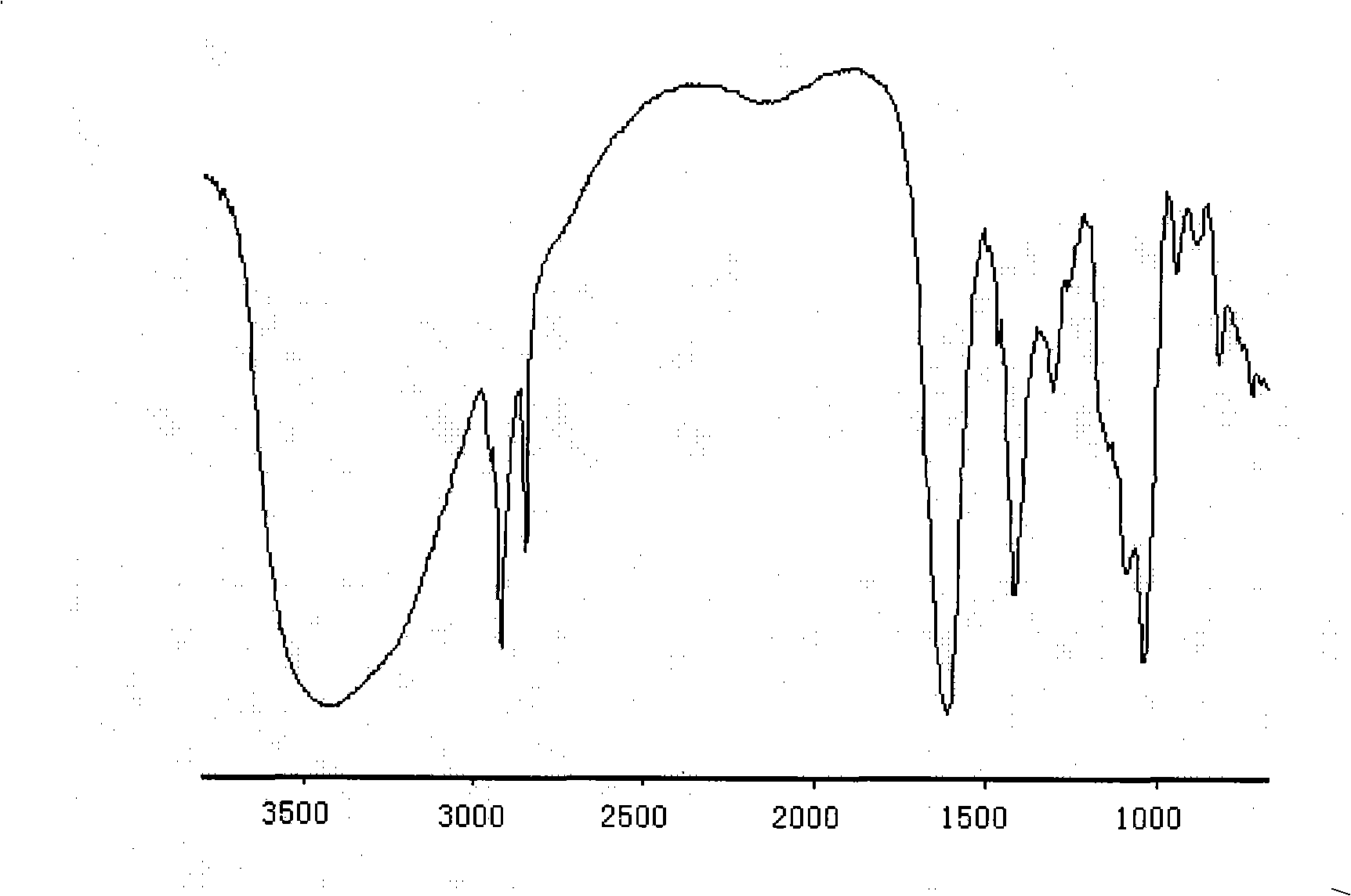

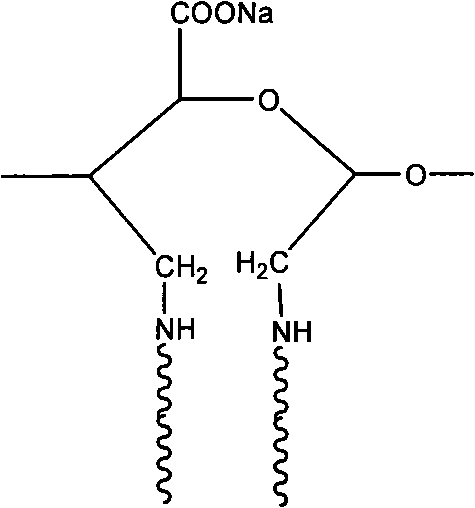

[0020] The introduction of the hydrophobic alkyl segment is in the reducing agent sodium cyanoborohydride (NaCNBH 3 ) under the action. Take 2.0g OSA and dissolve in 100mL phosphate buffer (pH 7.0) to make a uniform solution, add 0.46gNaCNBH 3 , then add 50mL of methanol solution containing dodecylamine 0.01-0.04g / mL, stir...

Embodiment 2

[0024] Dissolve 400mg SA-NHR polymer in 40mL water, stir this high viscosity liquid mechanically for 8h (speed 5000rpm), add drug 100mg ibuprofen into the polymer solution, and disperse in 2%w / v. In 40mL NaCl aqueous solution, add NaCl (2% w / v) and CaCl after stirring at high speed 2 (3% w / v) 1:1 (v / v) mixed solution 80 mL.

[0025]

[0026] The obtained microspheres were centrifuged, the surface was rinsed with deionized water, and dried. In vitro simulated release was performed in pure water and PBS buffer (pH 6.8). Taking sodium alginate gel microspheres modified with dodecylamine as an example, the embedding rates of the hydrophobic drug ibuprofen were 69.3%, 12%, and 15% respectively for SA-NHR with grafting rates of 8%, 12%, and 15%. 74.6%, 80.3%, while the original sodium alginate is only 46.6%.

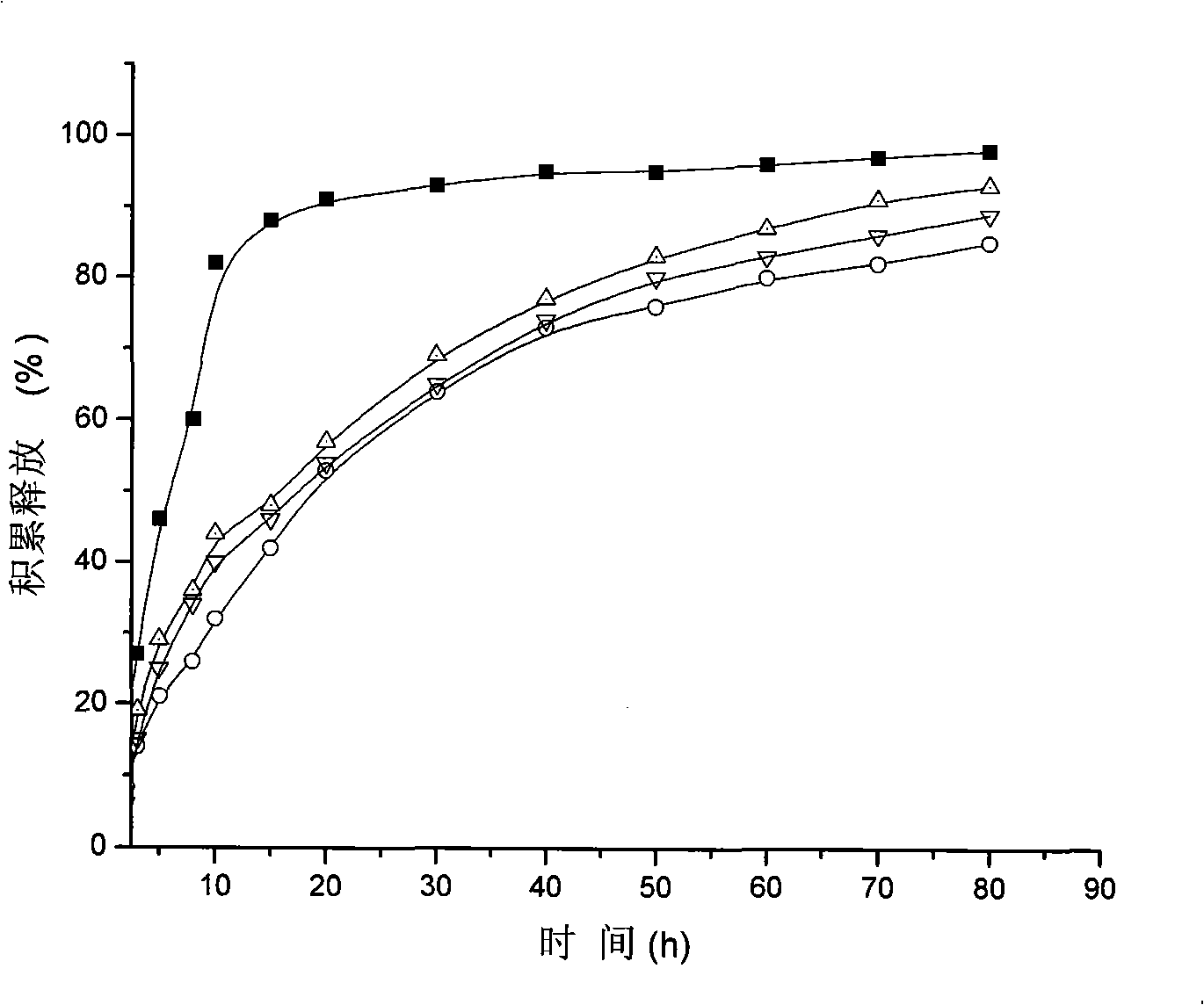

[0027] Sustained release results such as figure 2 As shown, the modified SA-NHR microspheres stabilize the polymer network due to the hydrophobic association, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com