Polymer/porous ceramics structure and function integrated gradient composite material and preparation method thereof

A technology of porous ceramics and composite materials, applied in chemical instruments and methods, ceramic layered products, synthetic resin layered products, etc., can solve the problems of easy delamination of multilayer composite structure materials, poor safety and reliability, etc., and achieve excellent mechanical properties Excellent performance, good thermal stability, and the effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

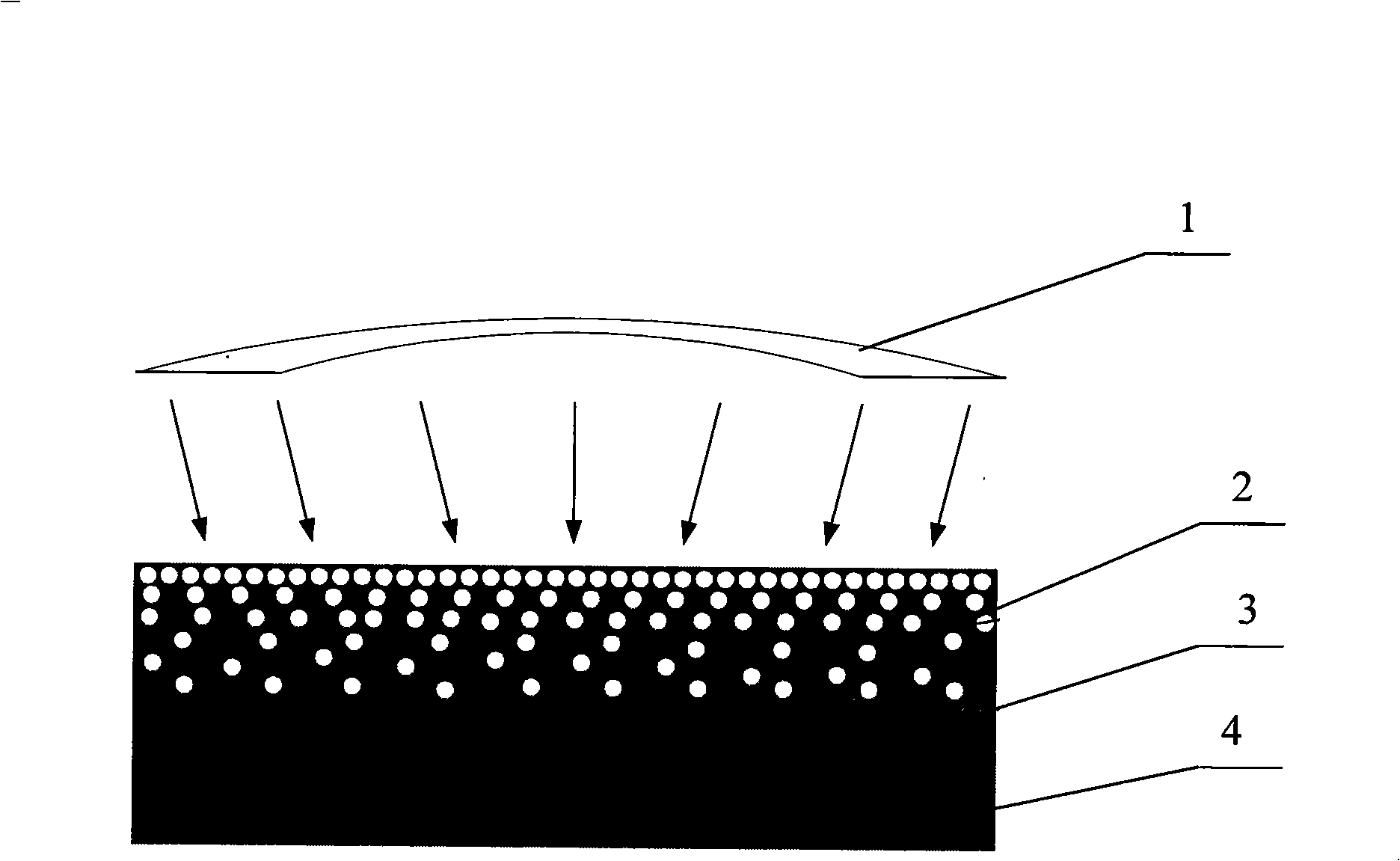

[0012] Embodiment 1: In this embodiment, the polymer / porous ceramic structure-function integrated gradient composite material is made from a polymer layer, a gradient connection layer and a ceramic layer from the inside to the outside; the polymer layer is made of polymer-impregnated fibers The gradient connection layer is made of fiber reinforcement impregnated with polymer and ceramic slurry, of which the gradient connection layer has two to five layers, and the content of the ceramic slurry in each layer of the gradient connection layer increases gradually from the inside to the outside. The polymer content gradient is reduced; the ceramic layer is made of fiber reinforcement impregnated with ceramic slurry.

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment is different from Embodiment 1 in that: the fiber reinforcement in the gradient connection layer is quartz fiber or glass fiber. Others are the same as in the first embodiment.

[0014] The fiber reinforcement in this embodiment is in the form of chopped fibers, continuous long fibers or three-dimensional fiber fabrics.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment is different from Embodiment 1 in that: the fiber reinforcement in the ceramic layer is quartz fiber or glass fiber. Others are the same as in the first embodiment.

[0016] The fiber reinforcement in this embodiment is in the form of chopped fibers, continuous long fibers or three-dimensional fiber fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com