Technique for preparing potassium sodium dehydroandroandrographolide succinic by using potassium dehydroandrographolide succinate

A technology of andrographolide and Chuanhuning, which is applied in antipyretics, organic chemistry, non-central analgesics, etc., can solve the problems of unstable pH value of preparations, incomplete removal of impurities, low product yield, etc., and achieve less impurities , Reduce energy consumption, high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] Weigh 200g of Chuanhuning, add 650ml of absolute ethanol to make a suspension, weigh another 29.5g of sodium bicarbonate, add water to dissolve it in a water bath, add the Chuanhuning suspension in a 45°C water bath dropwise sodium bicarbonate solution, slowly Add dropwise and stir until the liquid medicine is clear and impurities are precipitated out at the same time, pass through a 0.22 μm membrane, add 1500ml of absolute ethanol under stirring, stir for 10 minutes, and let it stand at room temperature for 15 hours to naturally crystallize. Filter, wash twice with 1000ml of absolute ethanol, filter, and dry under reduced pressure at 50°C to obtain 176g of light yellow powder.

Embodiment 2

[0142] Weigh 400g of Chuanhuning, add 2000ml of absolute ethanol to make a suspension, weigh another 63.2g of sodium bicarbonate, add water to dissolve it in a water bath, add the Chuanhuning suspension in a 50°C water bath dropwise with sodium bicarbonate solution, slowly Slowly add dropwise and stir until the liquid medicine is clear and impurities are precipitated at the same time. After passing through a 0.22μm membrane, add 3600ml of absolute ethanol under stirring, stir for 20 minutes, and let it stand at room temperature for 18 hours to naturally crystallize. Filter, wash 3 times with 2300ml of absolute ethanol, filter, and dry under reduced pressure at 55°C to obtain 336g of light yellow powder.

Embodiment 3

[0144] Weigh 600g of Chuanhuning, add 3600ml of absolute ethanol to make a suspension, weigh another 91.3g of sodium bicarbonate, add water to dissolve it in a water bath, add the Chuanhuning suspension in a 60°C water bath dropwise with sodium bicarbonate solution, slowly Slowly add dropwise, stir until the liquid medicine is clear, and impurities are precipitated at the same time, pass through a 0.22 μm membrane, add 7200ml of absolute ethanol under stirring, stir for 30 minutes, and stand at room temperature for 20 hours, and crystallize naturally. Filter, wash 3 times with 3600ml of absolute ethanol, filter, and dry under reduced pressure at 60°C to obtain 498g of light yellow powder.

PUM

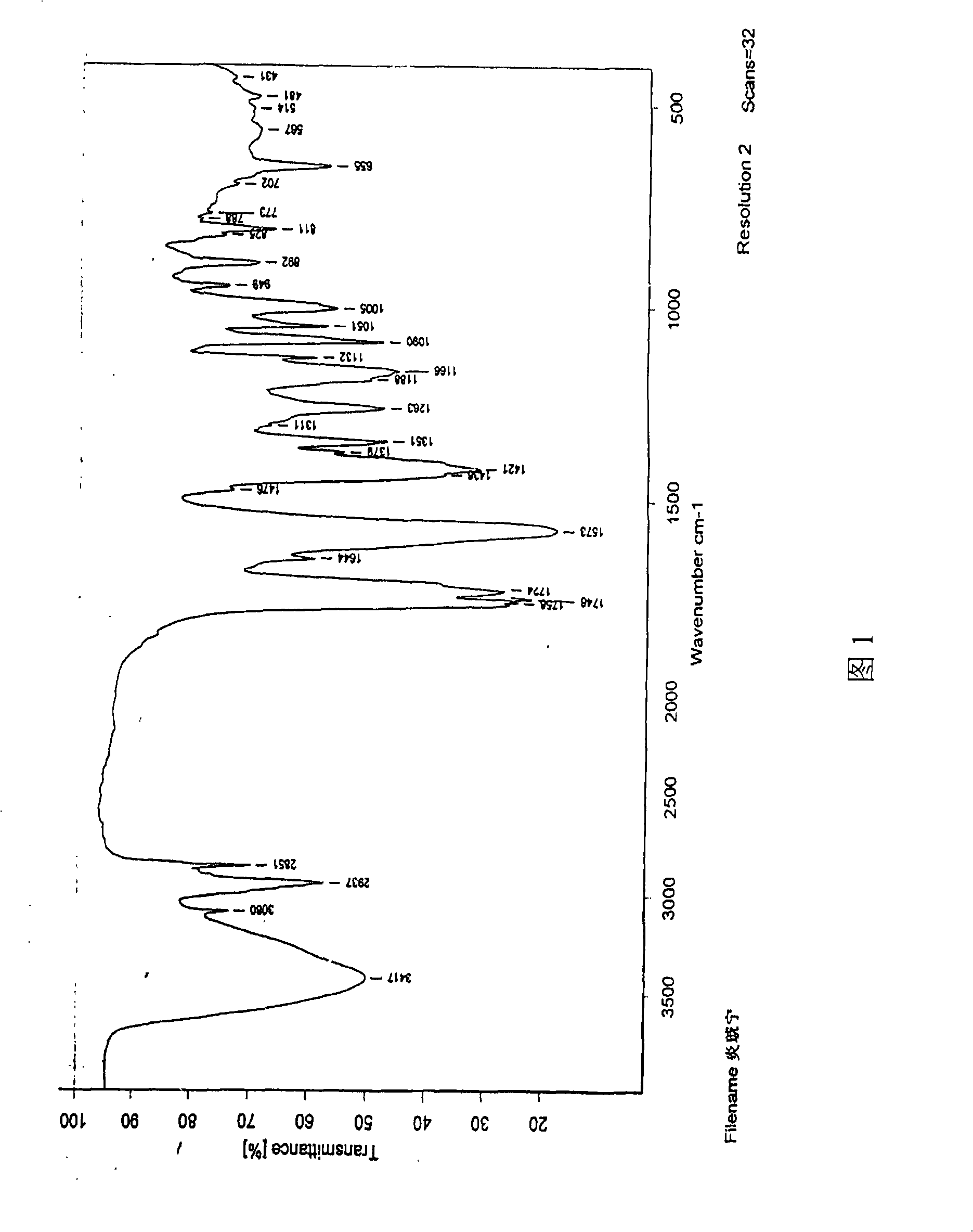

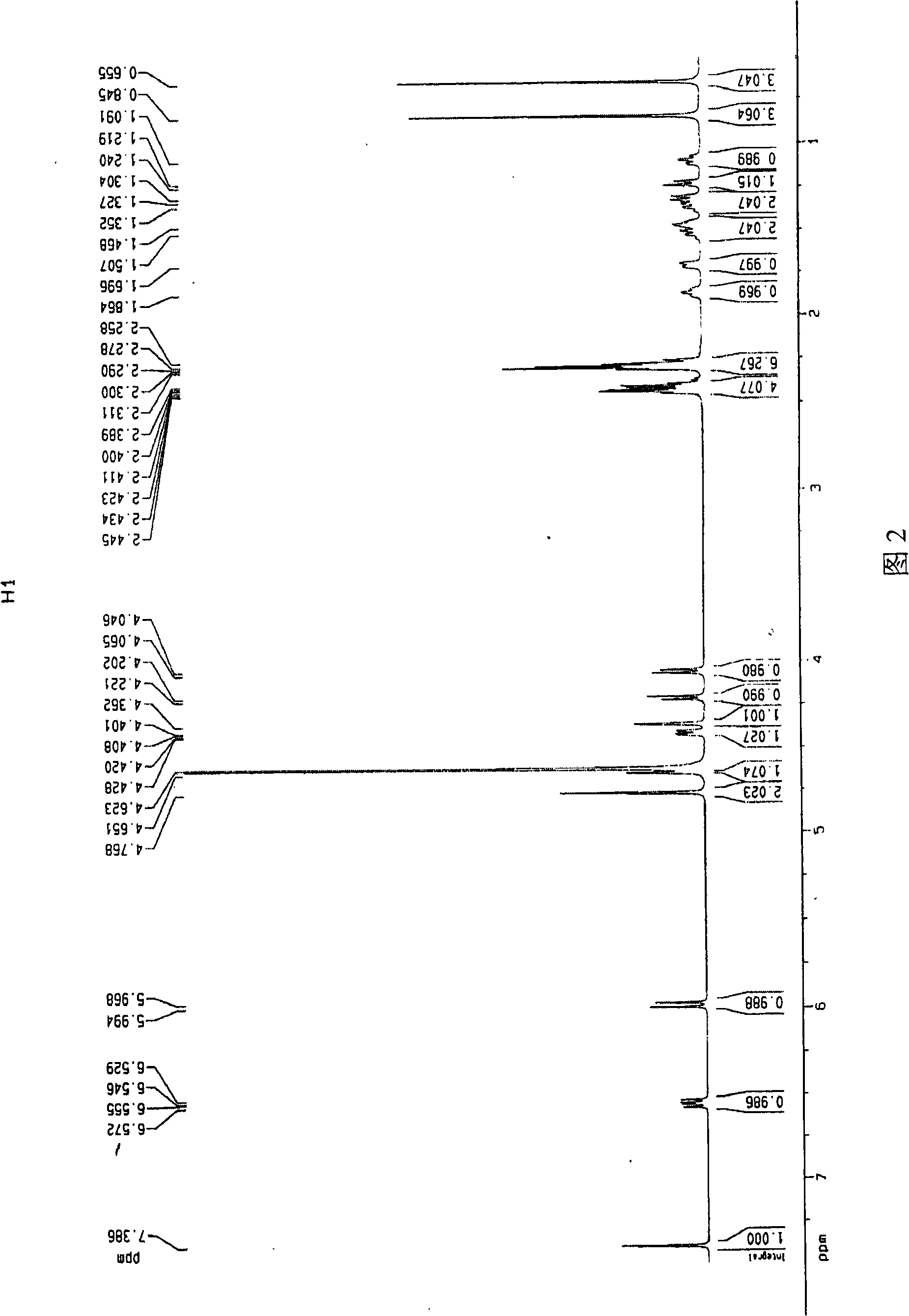

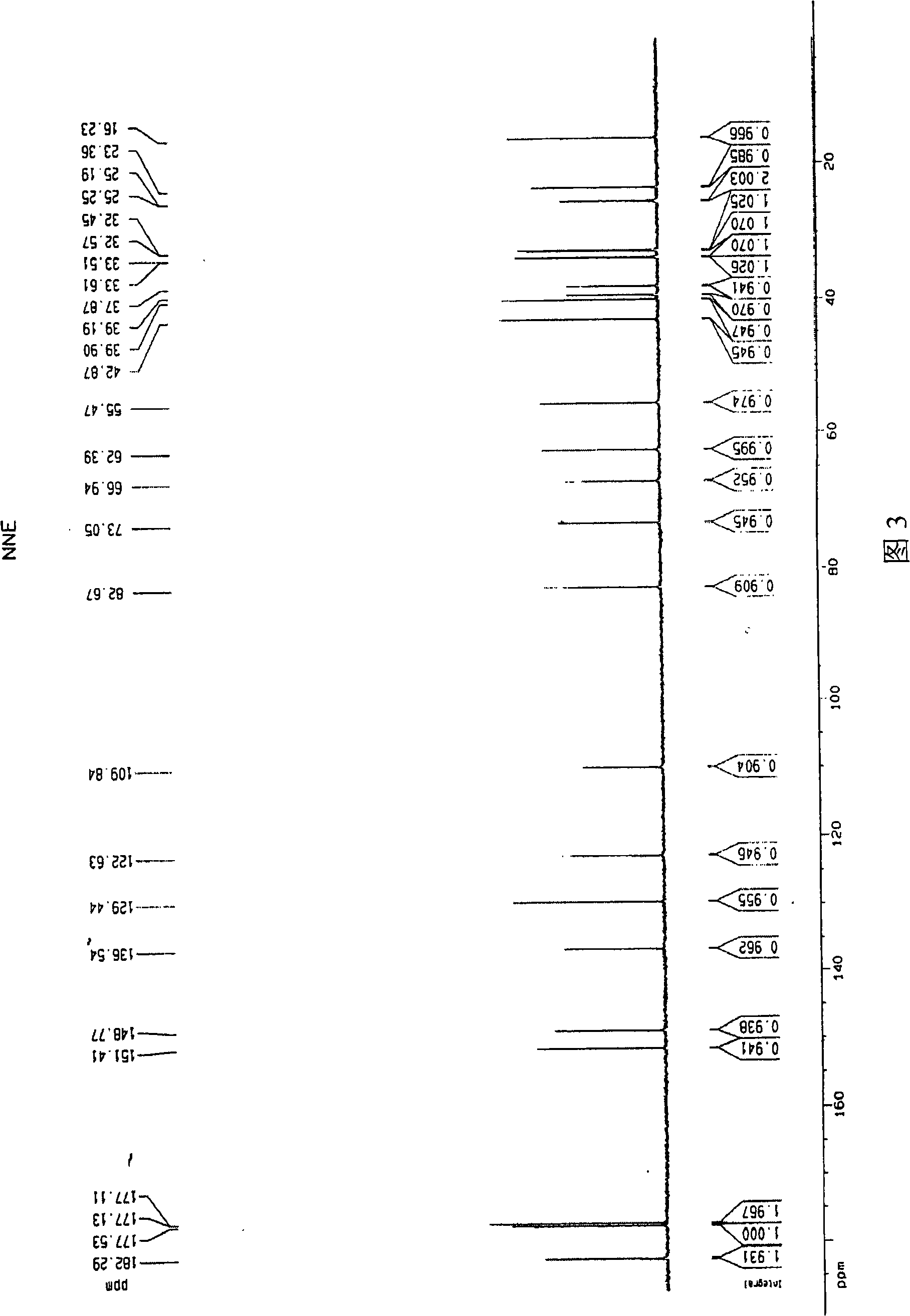

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com