Quench hardening type easy-cutting mirror-surface plastic die steel

A plastic mold steel, free cutting technology, applied in the field of advanced plastic mold steel and steel materials, can solve the problems of insufficient corrosion resistance, insufficient wear resistance, affecting the service life of the mold, and achieve the effect of low cost and low cost

Inactive Publication Date: 2008-09-10

NINGBO ZHEDONG PRECISION CASTING

View PDF4 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The pre-hardening hardness of 4CrNiMnMoVSCa (4NiSCa) and 5CrNiMnMoVSCa (5NiSCa) is 35-45HRC. Due to the addition of easy-cutting elements S and Ca, it has good machinability and mirror polishing, but the wear resistance is not enough, which affects the mold Service life, and not corrosion resistance; 8Cr2MnMoVS (8Cr2S) compared with 4NiSCa and 5NiSCa, the hardness has been greatly improved, pre-hardened hardness can reach 40 ~ 48HRC, is a kind of machinability, wear resistance and polishability New steel grades, but also lack of corrosion resistance

There is no specially developed hardened plastic mold steel in the die steel industry. The existing steel grades are replaced by hot work die steel and cold work die steel. Incorporated directly with 4Cr5MoSiV1, SMCr12Mo1V1 is directly incorporated by cold work die steel Cr12Mo1V1, and in terms of metallurgical process, it needs to be refined and processed by ESR, VAR and other processes. The hardness of these steels can reach 45-60HRC, with good polishing, etching and mechanical performance, but poor processing performance at high hardness, and high material cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0027] The present invention will be further described below through embodiment.

[0028] The manufacturing process of the plastic mold steel 4Cr8NiBCu of the present invention is as follows: electric arc furnace smelting→casting mold steel ingot→primary forging blank opening→hot annealing→blank cutting→secondary forging module→spheroidizing annealing→heat treatment (quenching and tempering)→finished product module into library.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

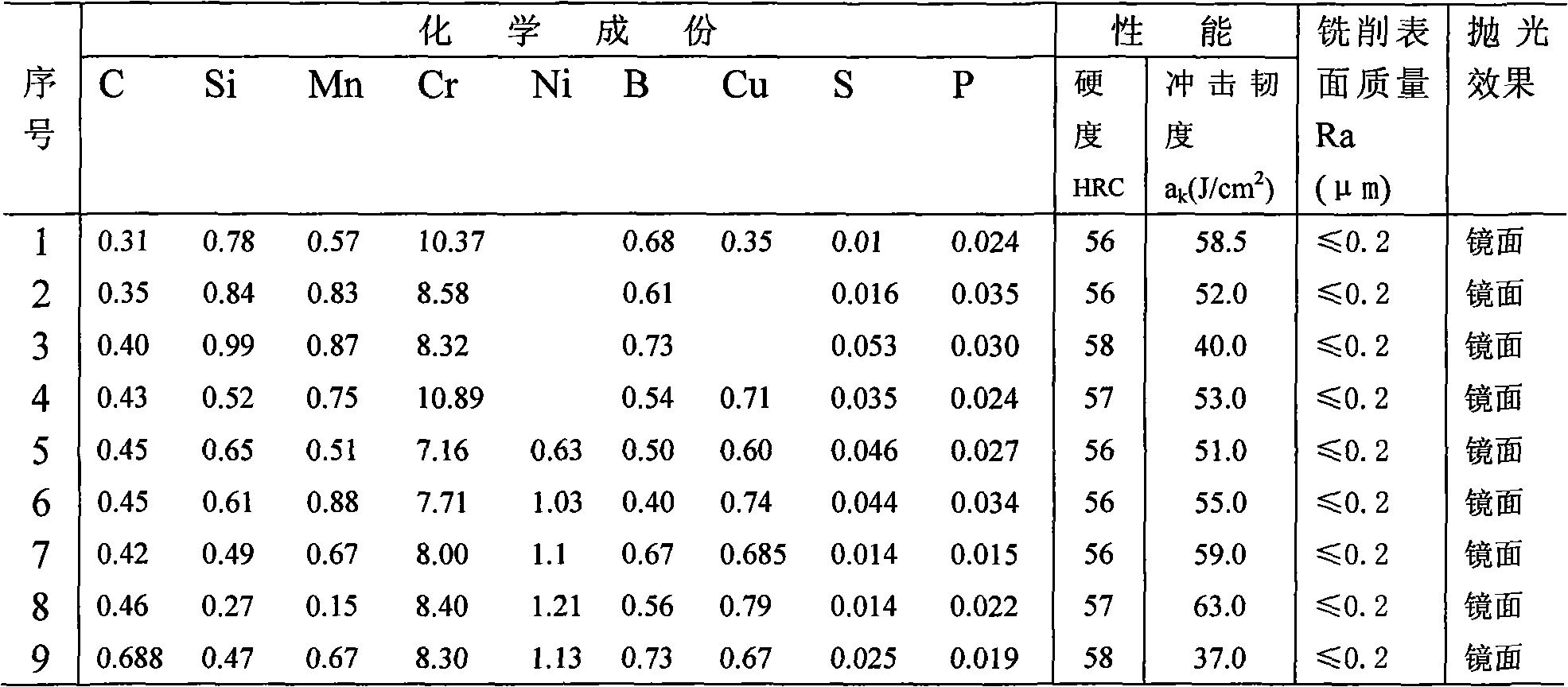

The invention relates to a harden quench type easy-cutting anticorrosive mirror face plastic die steel which is characterized by comprising the follow chemical compositions in percentage by weight (wt percent): 0.30 to 0. 70 percent of C, less than or equal to 1.0 percent of Si, less than or equal to 0.9 percent of Mn, 7.0 to 11.5 per cent of Cr, less than or equal to 2.5 percent of Ni, 0.03 to 0.75 percent of B, less than or equal to 1.0 percent of Cu, less than or equal to 0.1 percent of S, less than or equal to 0.04 percent of P, the balance being Fe and inevitable impurities. A metallographic structure consists of a martensite substrate and a few eutectic borides; mass fine granular secondary boron carbides are distributed on the martensite substrate and can be quenched to be hard; the hardness is between 56 HRC and 58 HRC; the harden quench type easy-cutting anticorrosive mirror face plastic die steel has easy cutting, corrosion resistance and mirror face polishing performance.

Description

technical field [0001] The hardened free-cutting mirror plastic mold steel involved in the invention relates to the field of iron and steel materials, especially the field of high-grade plastic mold steel. Background technique [0002] The ideal plastic mold steel is the best combination of hardenability, machinability, mirror polishing and corrosion resistance. Existing plastic mold steels with one or more of the aforementioned properties include: [0003] Pre-hardened plastic mold steel. SM3Cr2Mo (P20) and SM3Cr2NiMo (P20+Ni) are common pre-hardened plastic mold steels, the pre-hardened hardness is 28-37HRC, P20+Ni has better hardenability and mechanical properties than P20, and is called advanced plastic mold Steel, the processing performance of these two mold steels is acceptable, except for a small amount of high-quality steel, it is difficult to achieve a mirror effect when polished. Due to the low hardness and poor wear resistance, the mold life is not long and it ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/54

Inventor 胡开华

Owner NINGBO ZHEDONG PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com