Environmental protection highly effective additive for electrolyzing selenium-free manganese metal and preparation method thereof

A technology of metal manganese and additives, which is applied in the field of metallurgy, can solve the problems of reducing the amount of selenium, and achieve the effects of reducing the formation of manganese knots on the surface, convenient and safe operation, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

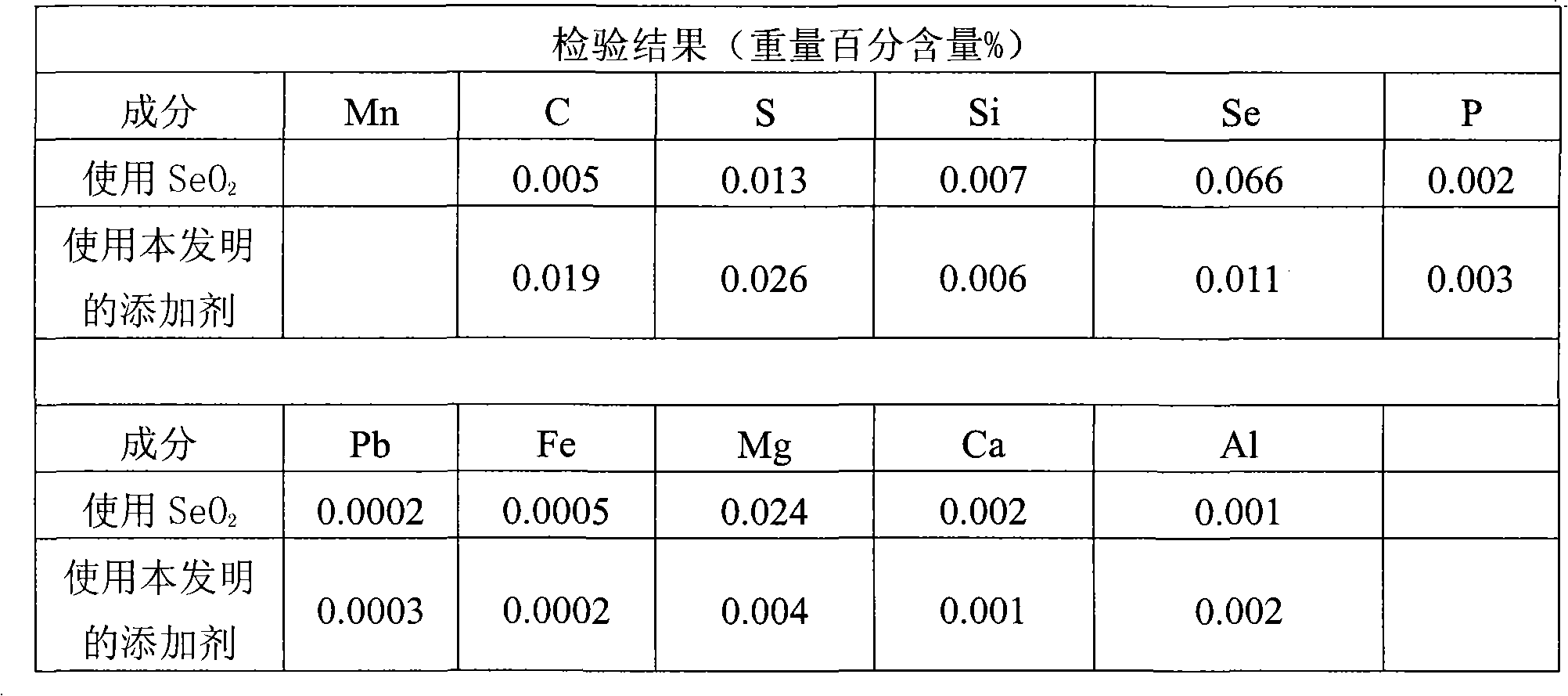

Image

Examples

Embodiment 1

[0015] The additive for environmentally friendly and efficient electrolysis of selenium-free metal manganese is prepared from water-soluble polyacrylamide, animal glue, polyethylene glycol, boric acid and water. The weight percentage of each raw material is: water-soluble polyacrylamide 8%, Animal glue 11%, polyethylene glycol 20%, boric acid 4%, water 57%.

[0016] The water-soluble polylactam is cationic with a molecular weight of 8 to 12 million; for example, Guangzhou Huabei Chemical Technology Co., Ltd. has a cationic 12 million.

[0017] The animal glue is bone glue, such as the industrial bone glue produced by Hebei Hengshui Brothers Gelatin Factory.

[0018] The molecular weight of the polyethylene glycol (PEG) is 2000-6000, such as PEG4000 produced by Fushun Jiahua Polyurethane Co., Ltd.

[0019] The method for preparing the above environmentally-friendly and efficient electrolytic selenium-free metal manganese additive includes the following steps:

[0020] 1) The weight...

Embodiment 2

[0027] The additive for environmentally friendly and efficient electrolysis of selenium-free metal manganese is prepared from water-soluble polyacrylamide, animal glue, polyethylene glycol, boric acid and water. The weight percentage of each raw material is: water-soluble polyacrylamide 5%, Animal glue 8%, polyethylene glycol 30%, boric acid 5%, water 52%.

[0028] The water-soluble polyacrylamide is cationic with a molecular weight of 8 million to 12 million; for example, CPF-800 produced by Gongyi Jinyuan Chemical Co., Ltd.

[0029] The animal glue is bone glue, such as the industrial bone glue produced by Dongguan Ande Gelatin Co., Ltd.

[0030] The molecular weight of the polyethylene glycol (PEG) is 2000-6000, such as PEG6000 produced by Fushun Jiahua Polyurethane Co., Ltd.

[0031] The method for preparing the above environmentally-friendly and efficient electrolytic selenium-free metal manganese additive includes the following steps:

[0032] 1) The weight percentage of eac...

Embodiment 3

[0039] The additive for environmentally friendly and efficient electrolysis of selenium-free metal manganese is prepared from water-soluble polyacrylamide, animal glue, polyethylene glycol, boric acid and water. The weight percentage of each raw material is: water-soluble polyacrylamide 10%, Animal glue 15%, polyethylene glycol 40%, boric acid 3%, water 32%.

[0040] The water-soluble polyacrylamide is cationic, with a molecular weight of 8 million to 12 million, such as CPF-1000 or CPF-1200 from Jiangdu Runhua Water Purifying Agent Co., Ltd.

[0041] The animal glue is gelatin, such as industrial gelatin produced by Hebei Hengshui Brothers Gelatin Factory.

[0042] The molecular weight of the polyethylene glycol (PEG) is 2000-6000. Such as PEG2000 produced by Fushun Jiahua Polyurethane Co., Ltd.

[0043] The method for preparing the above environmentally-friendly and efficient electrolytic selenium-free metal manganese additive includes the following steps:

[0044] 1) According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com