An electric harmonic reciprocating line motion impact device

A technology of reciprocating linear motion and percussion devices, which is applied in electromechanical devices, percussion drilling, reciprocating drilling rigs, etc., can solve the constraints on the development and application of electric motor percussion equipment, large pneumatic rock drilling system equipment and facilities, investment and operation High maintenance costs and other issues, to achieve significant energy saving effects, improve working conditions, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

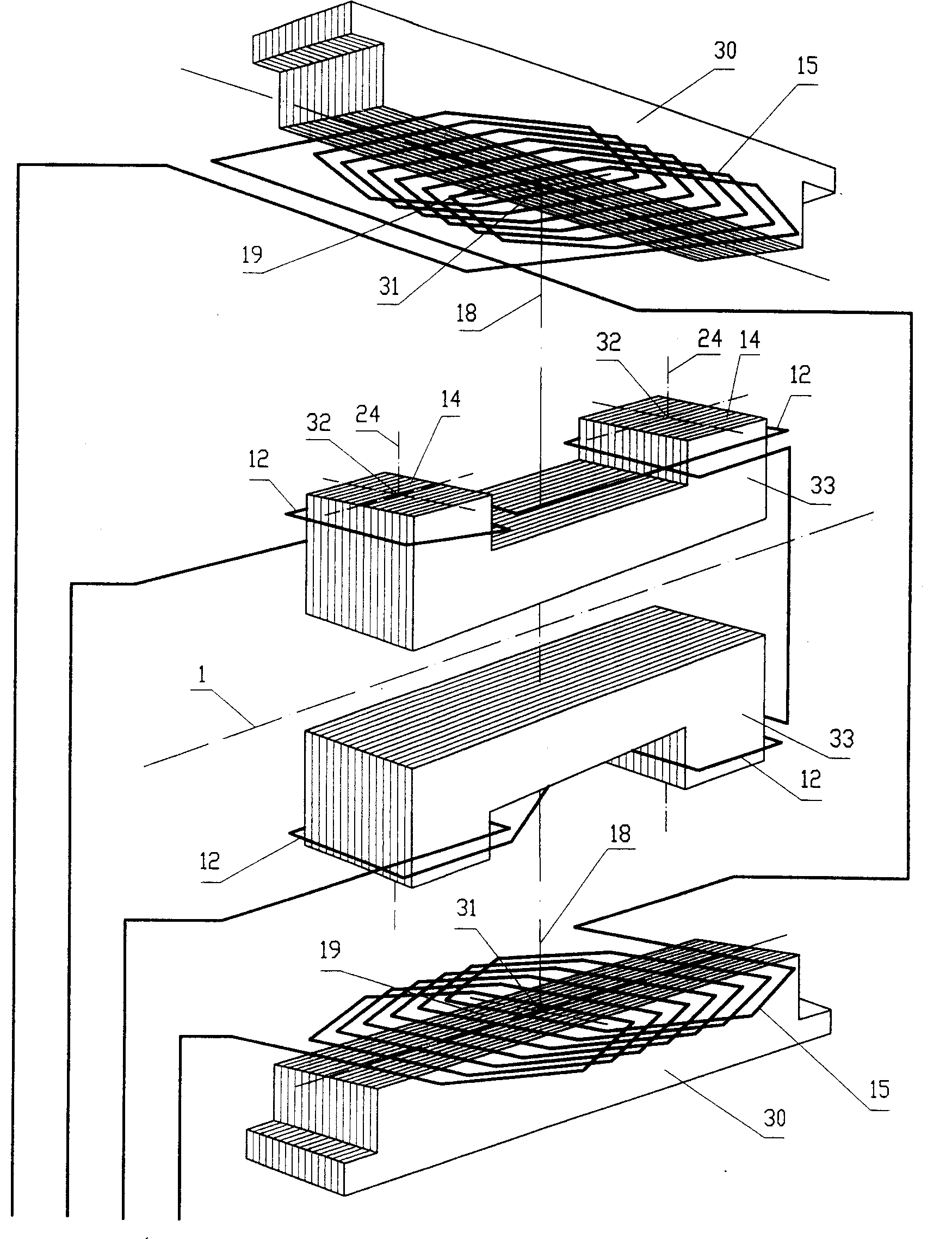

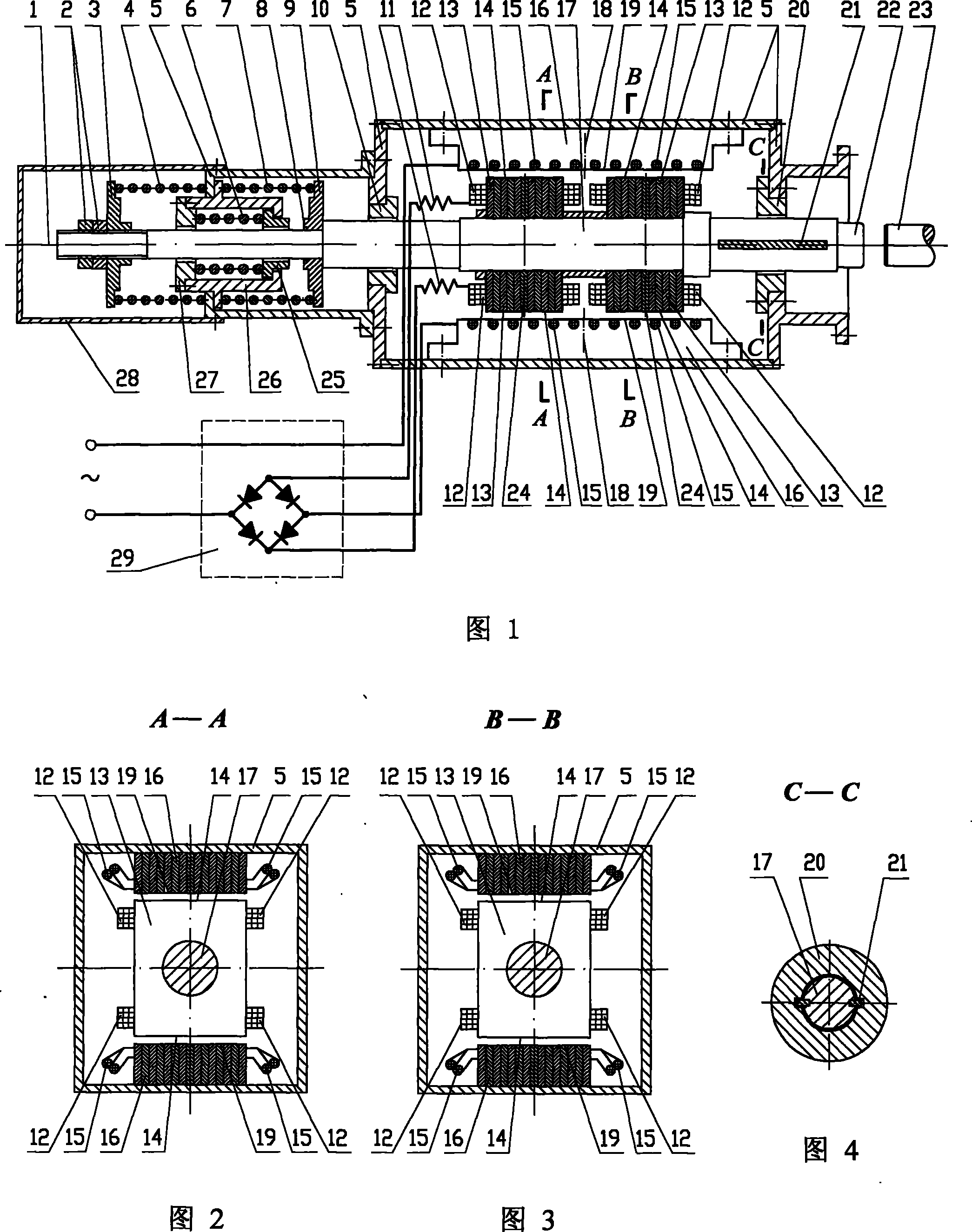

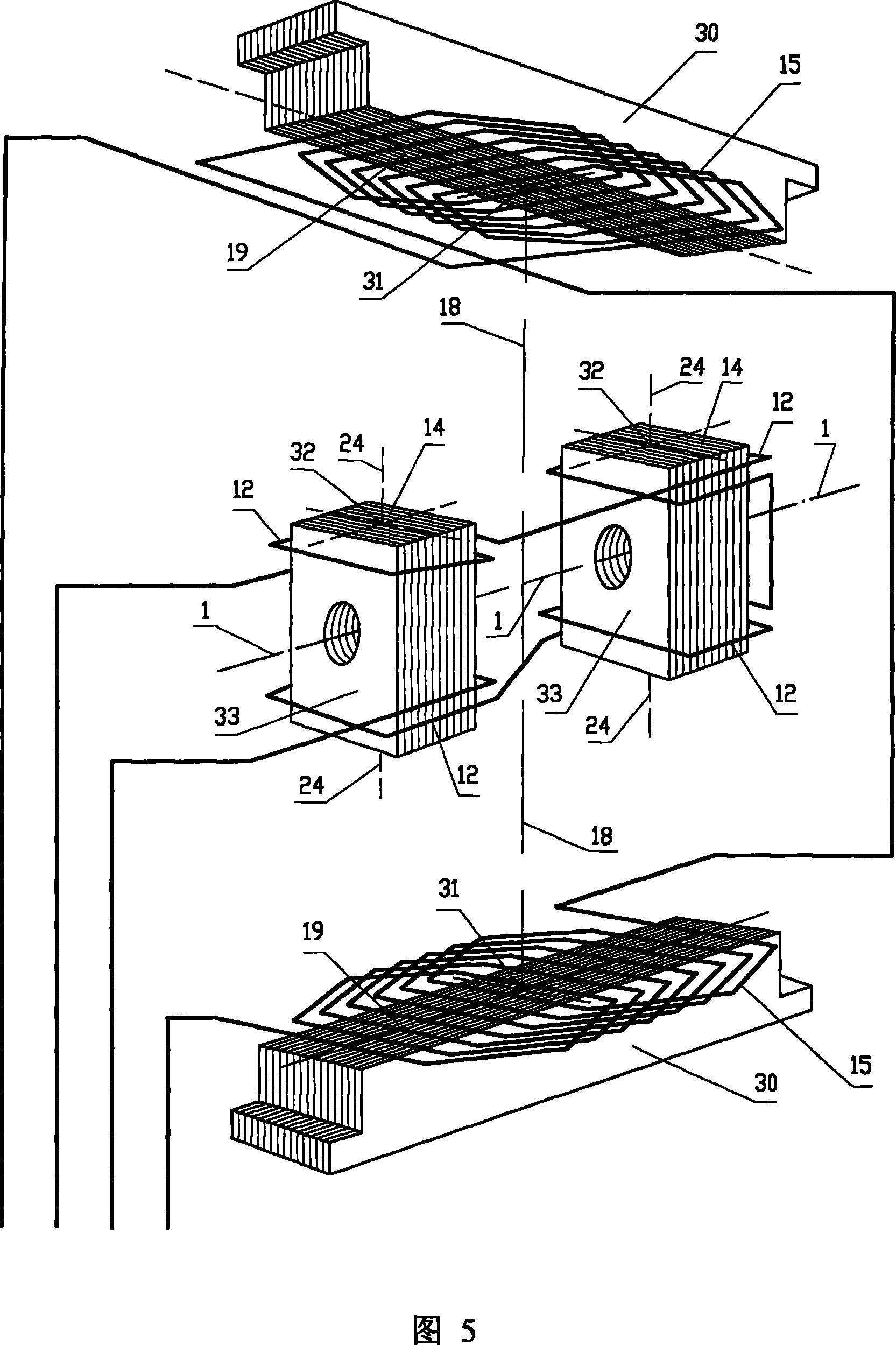

[0045] Such as figure 1 As shown, a sliding sleeve is provided on the frame 5, and the sliding sleeve includes two ordinary sliding sleeves 10 and an anti-twist sliding sleeve 20; It can slide linearly in the two sliding sleeves; two sections of movable iron core 13 are arranged on the impact rod 17, and the movable iron core 13 is composed of stacked silicon steel sheets, and the surface of the silicon steel sheets is provided with insulating paint film or oxide film insulating medium; Two sections of movable iron core 13 are spaced and fixed on the impact rod 17 along the axial direction of the impact rod. The axial direction of the impact rod refers to the direction parallel to the axial center line 1 of the impact rod; Movable iron core coils 12, each movable iron core coil 12 is an electromagnetic pole, and the pole coupling of two movable iron cores 13 is connected in series to form a pair of electromagnetic poles; Two fixed iron cores 16 are set on the frame 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com